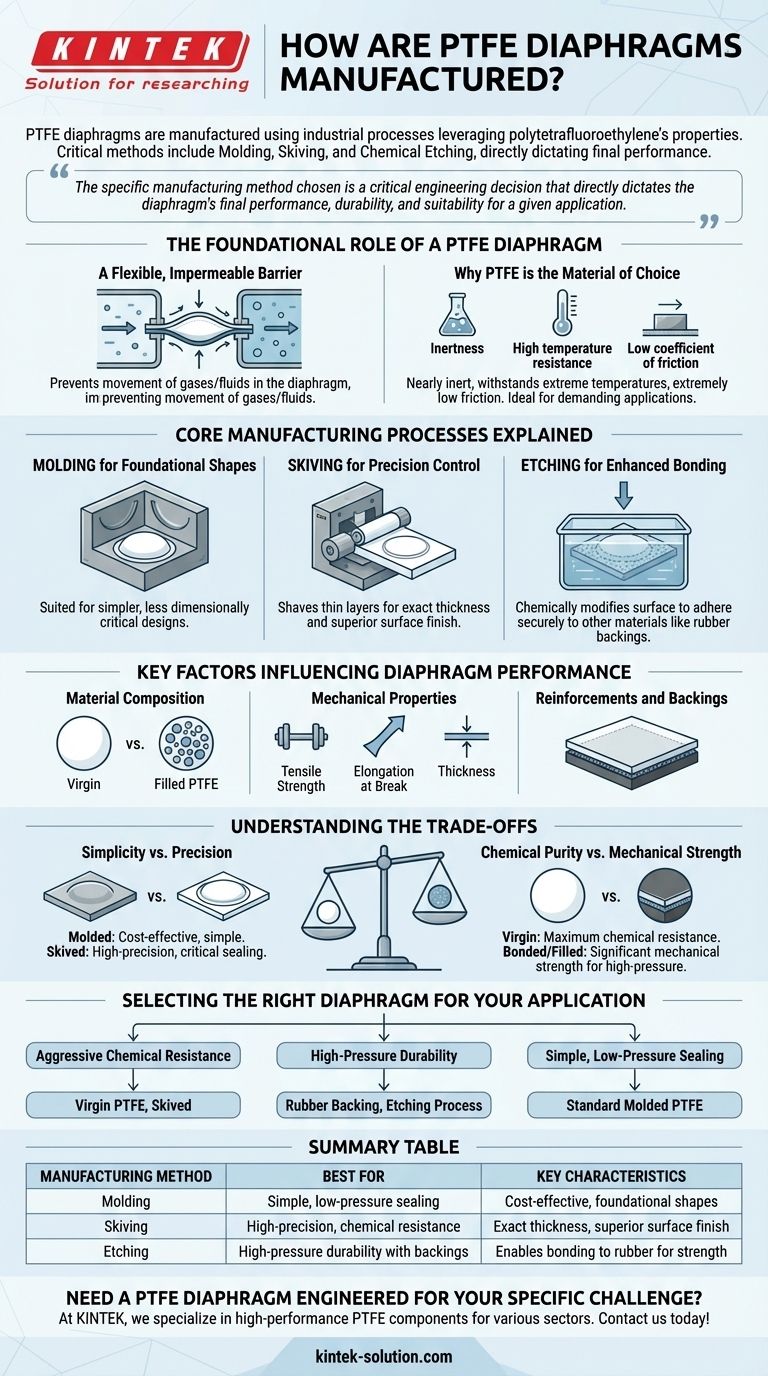

PTFE diaphragms are manufactured using a few key industrial processes designed to leverage the unique properties of polytetrafluoroethylene. The primary methods include molding for creating simpler designs, skiving for achieving precise thickness and shape control, and chemical etching as a surface treatment to enhance bonding with other materials like rubber backings.

The specific manufacturing method chosen is not arbitrary; it is a critical engineering decision that directly dictates the diaphragm's final performance, durability, and suitability for a given application.

The Foundational Role of a PTFE Diaphragm

A Flexible, Impermeable Barrier

At its core, a PTFE diaphragm functions as a flexible barrier between two chambers. Its purpose is to prevent the movement of fluids, gases, or contaminants from one side to the other while allowing for pressure changes or mechanical motion.

Why PTFE is the Material of Choice

PTFE, or polytetrafluoroethylene, is selected for its exceptional material properties. It is nearly inert to all chemicals, can withstand extreme temperatures, and has an extremely low coefficient of friction.

These characteristics make PTFE diaphragms the ideal choice for demanding applications where other materials would quickly fail due to chemical attack, high heat, or abrasive conditions.

Core Manufacturing Processes Explained

Molding for Foundational Shapes

Molding is a common method used to form the basic shape of the diaphragm. This process is generally suited for simpler, less dimensionally critical designs.

Skiving for Precision Control

Skiving is a machining process that shaves thin, precise layers from a solid block of PTFE. This technique is essential for applications requiring exact thickness and superior surface finish, which are critical for consistent performance and sealing.

Etching for Enhanced Bonding

PTFE is famously non-stick, which makes it difficult to bond to other materials. To overcome this, the diaphragm surface can be chemically etched.

This process modifies the surface chemistry of the PTFE, allowing it to adhere securely to other materials, such as a rubber backing, for added strength and flexibility.

Key Factors Influencing Diaphragm Performance

Material Composition

The diaphragm can be made from virgin PTFE for maximum chemical purity or filled PTFE, which includes additives to enhance properties like wear resistance or reduce creep.

Mechanical Properties

Key technical specifications like tensile strength (resistance to pulling forces) and elongation at break (how much it can stretch before failing) are critical indicators of mechanical durability. The diaphragm's thickness is also a primary factor in its pressure resistance and flexibility.

Reinforcements and Backings

For high-pressure or physically demanding applications, a PTFE diaphragm is often combined with a rubber backing. The PTFE provides the chemical resistance, while the rubber backing provides additional strength, resilience, and sealing capability.

Understanding the Trade-offs

Simplicity vs. Precision

A simple molded diaphragm may be sufficient and more cost-effective for a basic application. However, a skived diaphragm offers far greater control over thickness and flatness, which is non-negotiable for high-performance, critical sealing environments.

Chemical Purity vs. Mechanical Strength

Using pure, virgin PTFE ensures the highest possible chemical resistance. However, a diaphragm bonded to a rubber backing or made from filled PTFE gains significant mechanical strength and durability, which may be a necessary trade-off in abrasive or high-pressure systems.

Selecting the Right Diaphragm for Your Application

Understanding the manufacturing process empowers you to select the correct component for your specific engineering challenge.

- If your primary focus is aggressive chemical resistance: A diaphragm made from virgin PTFE with a precisely skived thickness is the optimal choice.

- If your primary focus is high-pressure durability: A diaphragm with a rubber backing, enabled by the etching process, will provide the necessary mechanical strength.

- If your primary focus is a simple, low-pressure sealing task: A standard molded PTFE diaphragm may provide the required performance cost-effectively.

By matching the manufacturing method to your operational demands, you ensure reliability and longevity for your equipment.

Summary Table:

| Manufacturing Method | Best For | Key Characteristics |

|---|---|---|

| Molding | Simple, low-pressure sealing | Cost-effective, foundational shapes |

| Skiving | High-precision, chemical resistance | Exact thickness, superior surface finish |

| Etching | High-pressure durability with backings | Enables bonding to rubber for strength |

Need a PTFE diaphragm engineered for your specific challenge? At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom diaphragms for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the chemical purity of virgin PTFE, the precision of skived layers, or the reinforced strength of a bonded design, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a component that delivers reliability and longevity.

Contact us today to discuss your application requirements and let our precision production capabilities work for you!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are PTFE gaskets and how are they made? A Guide to High-Performance Sealing Solutions

- Why is high temperature stability important for Teflon gland fillers? Ensuring Leak-Free Seals in Harsh Chemical Processes

- How do energized PTFE seals work? Achieve Reliable Sealing from Zero to High Pressure

- How do PTFE-coated O-rings contribute to system reliability? Enhance Seal Life and Performance

- What types of PTFE machined parts are commonly produced? Essential Components for Demanding Industries

- What factors should be considered when selecting between PTFE and EPDM valve seats for butterfly valves? Ensure Long-Term Reliability and Avoid Costly Failures

- What printing applications are Teflon sheets suitable for? Achieve Flawless Heat Transfers

- Why is ePTFE preferred over PTFE in certain applications? Unlock Superior Sealing & Filtration