In the electronics and electrical industries, PTFE rods are primarily utilized to fabricate high-performance wire insulation, critical components for printed circuit boards (PCBs), and insulators for high-voltage equipment. Their value comes from a unique combination of electrical, thermal, and chemical properties that other materials cannot easily match.

The core reason for PTFE's widespread use is not simply that it's an insulator, but that it maintains its exceptional electrical properties with extreme consistency across a wide range of frequencies, temperatures, and harsh chemical environments.

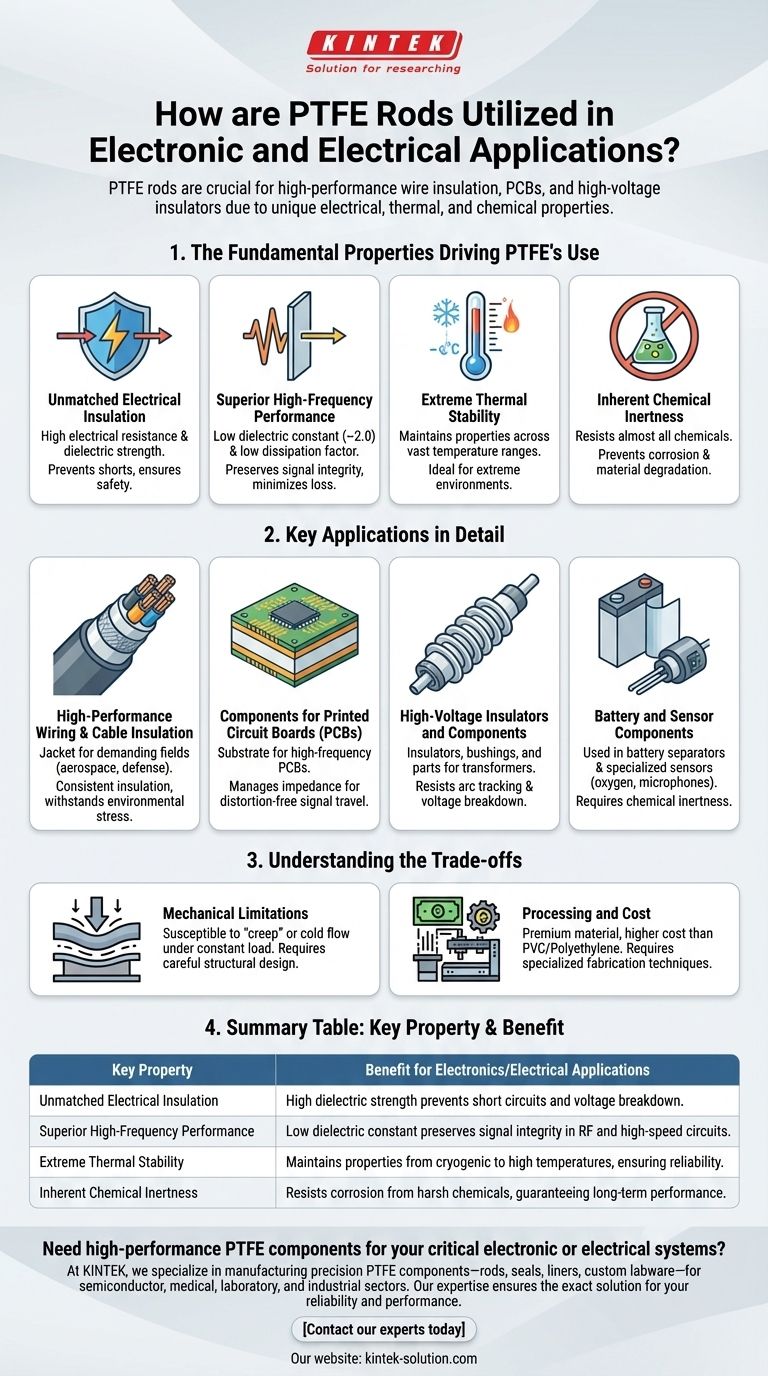

The Fundamental Properties Driving PTFE's Use

To understand where to use PTFE, we must first understand why it is so effective. Its highly symmetric molecular structure is the source of its most valuable characteristics.

Unmatched Electrical Insulation

PTFE is one of the best known electrical insulators. It exhibits extremely high electrical resistance and dielectric strength.

This means it strongly resists the flow of current and can withstand very high voltages before breaking down, preventing shorts and ensuring component safety.

Superior High-Frequency Performance

For applications like radio circuits and high-speed data components, PTFE's low dielectric constant (around 2.0) and low dissipation factor are critical.

These properties ensure that the material absorbs very little signal energy as it passes through, preserving signal integrity and minimizing loss, which is essential for high-frequency performance.

Extreme Thermal Stability

PTFE maintains its excellent electrical and mechanical properties over a vast temperature range.

This stability makes it ideal for components that operate in extreme heat or cold, from aerospace electronics to industrial transformers, without degrading or losing insulating capability.

Inherent Chemical Inertness

PTFE is almost universally inert, resisting virtually all industrial chemicals and solvents.

In electrical systems, this prevents corrosion and material degradation, ensuring the long-term reliability of insulators and protective jackets exposed to harsh environments.

Key Applications in Detail

These fundamental properties translate directly into specific, high-value applications where performance and reliability are non-negotiable.

High-Performance Wiring and Cable Insulation

PTFE is used as a jacket or insulator for wires and cables, especially in demanding fields like aerospace and defense.

Its ability to withstand high temperatures and provide consistent insulation protects critical wiring from environmental stress and electrical interference.

Components for Printed Circuit Boards (PCBs)

In high-frequency PCBs, PTFE is used as the substrate material.

Its low dielectric constant is essential for managing impedance and ensuring that high-speed digital or radio frequency (RF) signals travel without distortion or significant loss.

High-Voltage Insulators and Components

PTFE rods are machined into insulators, bushings, and other parts for transformers, capacitors, and motors.

The material's resistance to arc tracking and voltage breakdown is crucial for preventing failure in high-voltage environments.

Battery and Sensor Components

Due to its chemical inertness and insulating properties, PTFE is used for battery separators and electrodes.

It is also used in specialized sensors, such as oxygen sensors or microphones, where its unique material properties are required for proper function.

Understanding the Trade-offs

While its performance is exceptional, PTFE is not the default choice for every application. Acknowledging its limitations is key to using it effectively.

Mechanical Limitations

PTFE is a relatively soft material and can be susceptible to "creep" or cold flow, meaning it can deform over time when subjected to a constant load.

Design considerations must account for this, especially for structural parts that are under continuous compression.

Processing and Cost

PTFE is a premium performance material, and its cost is higher than that of more common insulators like PVC or Polyethylene.

Its fabrication also requires specialized techniques, which can add to the final component cost. Its use is therefore typically reserved for applications where lesser materials would fail.

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on specific engineering requirements.

- If your primary focus is high-frequency performance (e.g., RF circuits): PTFE's low and stable dielectric constant is its most critical advantage.

- If your primary focus is high-voltage insulation: Its excellent dielectric strength and resistance to arcing make it a primary candidate.

- If your primary focus is reliability in extreme environments: Its combined thermal stability and chemical inertness justify its use over less robust materials.

Ultimately, selecting PTFE is a decision to prioritize unwavering electrical performance and long-term reliability in demanding conditions.

Summary Table:

| Key Property | Benefit for Electronics/Electrical Applications |

|---|---|

| Unmatched Electrical Insulation | High dielectric strength prevents short circuits and voltage breakdown. |

| Superior High-Frequency Performance | Low dielectric constant preserves signal integrity in RF and high-speed circuits. |

| Extreme Thermal Stability | Maintains properties from cryogenic to high temperatures, ensuring reliability. |

| Inherent Chemical Inertness | Resists corrosion from harsh chemicals, guaranteeing long-term performance. |

Need high-performance PTFE components for your critical electronic or electrical systems?

At KINTEK, we specialize in manufacturing precision PTFE components—including rods, seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get the exact solution to meet your demanding requirements for reliability and performance.

Contact our experts today to discuss how our PTFE components can enhance your application's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the primary materials used for oil seals? NBR vs. PTFE for Your Application

- What post-machining treatments are applied to Teflon parts? Stabilize and Clean, Don't Modify.

- What is the temperature rating for PTFE gaskets? Maximize Performance from -200°C to 260°C

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What role does the stainless steel spring play in PTFE seals? The Engine for Reliable Sealing Performance

- What makes Teflon (PTFE) suitable for food handling equipment? Discover its Safety & Efficiency Benefits

- What can happen if excess pressure is applied during PTFE machining? Avoid Costly Part Failure and Deformation

- Why are expanded PTFE gaskets considered a reliable sealing solution? Achieve Leak-Free Performance in Demanding Environments