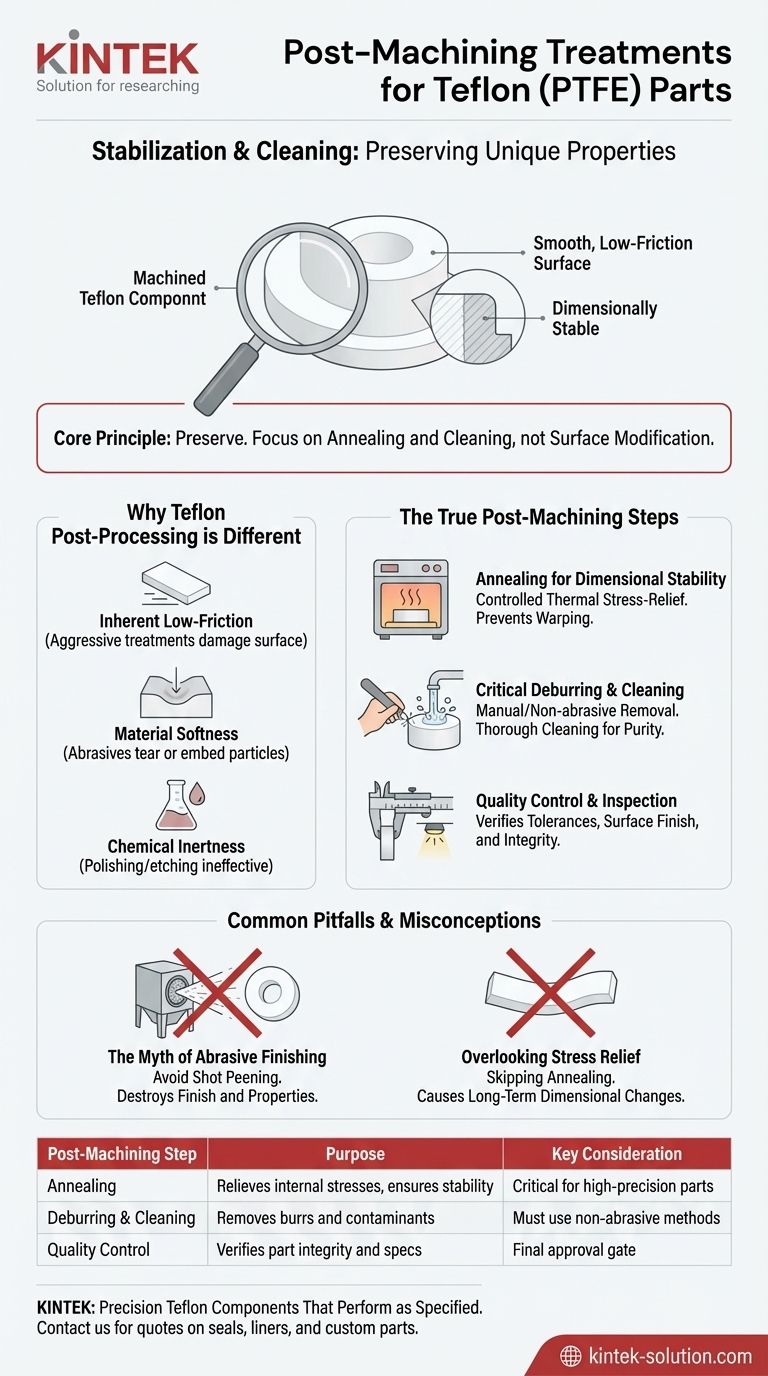

Unlike metals or harder plastics, post-machining treatments for Teflon (PTFE) parts focus on stabilization and cleaning rather than aggressive surface modification. Because of Teflon's inherent softness, chemical inertness, and low-friction surface, most conventional treatments are not only unnecessary but can be actively harmful to the component's final performance.

The core principle of post-processing Teflon is to preserve its unique properties. The most critical steps are not surface treatments like peening, but rather thermal annealing to ensure dimensional stability and meticulous cleaning to meet application-specific purity standards.

Why Teflon Post-Processing is Fundamentally Different

Teflon's material characteristics dictate a unique approach after machining. Understanding these properties is key to specifying the correct finishing steps.

Inherent Low-Friction Surface

Teflon has one of the lowest coefficients of friction of any solid material. Aggressive mechanical finishing processes like grinding, blasting, or shot peening would damage this surface, increase roughness, and negate the very reason Teflon is often chosen.

Material Softness

PTFE is a relatively soft polymer. Abrasive treatments can easily tear the material or embed media particles into the surface, which is unacceptable for nearly all applications, especially in medical, food, or semiconductor industries.

Chemical Inertness

Teflon is resistant to almost all chemicals. This means that chemical polishing or etching, common post-processing steps for other materials, are generally ineffective and unnecessary.

The True Post-Machining Steps for Teflon

Instead of altering the surface, the essential post-machining processes for Teflon are about ensuring the part is stable, clean, and free of machining artifacts.

Annealing for Dimensional Stability

Machining induces internal stresses in polymers. For high-precision Teflon components, a post-machining annealing (stress-relieving) cycle is the most critical treatment. This involves carefully heating the part in a controlled oven and then slowly cooling it to relax these internal stresses, preventing warping and ensuring long-term dimensional stability.

Critical Deburring and Cleaning

The machining process can create fine burrs or "hairs" on part edges. These must be removed carefully using manual or non-abrasive methods. Afterward, a thorough cleaning process is performed to remove any cutting fluids, oils, and handling contaminants to meet purity requirements.

Quality Control and Inspection

Every machined Teflon part undergoes rigorous inspection. This step confirms that dimensional tolerances, surface finish specifications, and overall part integrity meet the design requirements. This is less a "treatment" and more a final, critical gate before the part is approved.

Common Pitfalls and Misconceptions

Misapplying treatments intended for other materials can ruin Teflon components. It is crucial to avoid these common errors.

The Myth of Abrasive Finishing

Information suggesting that Teflon is shot peened is incorrect for standard applications. Shot peening is a process used to create compressive stress in metals to improve fatigue life. Applying this to soft Teflon would destroy its surface finish and functional properties. The goal with Teflon is to achieve the final finish during machining with sharp tools and proper techniques.

Overlooking Stress Relief

Skipping the annealing step is a primary cause of failure for high-tolerance Teflon parts. A part that is perfectly in-spec immediately after machining can slowly warp or change dimensions over time if internal stresses are not properly relieved.

Making the Right Choice for Your Application

Your final post-processing specification depends entirely on the component's function.

- If your primary focus is high dimensional stability: Mandate a post-machining annealing cycle to relieve internal stresses and prevent future deformation.

- If your primary focus is purity for medical or food-grade use: Specify a rigorous, validated cleaning process and strict handling protocols to prevent contamination.

- If your primary focus is optimal low-friction performance: Ensure the machining process itself is the final finishing step, using sharp tooling and precise parameters to achieve a smooth surface.

Ultimately, proper post-machining for Teflon is about stabilization and preservation, not aggressive surface alteration.

Summary Table:

| Post-Machining Step | Purpose | Key Consideration |

|---|---|---|

| Annealing | Relieves internal machining stresses to prevent warping and ensure dimensional stability. | A critical step for high-precision components. |

| Deburring & Cleaning | Removes fine burrs and contaminants to meet application-specific purity standards (e.g., medical, semiconductor). | Must use non-abrasive methods to avoid damaging the soft PTFE surface. |

| Quality Control & Inspection | Verifies that dimensional tolerances, surface finish, and part integrity meet design requirements. | The final gate before a part is approved for use. |

Need Precision Teflon Components That Perform as Specified?

At KINTEK, we understand that the true value of a PTFE part lies in its stable dimensions and flawless surface. Our post-machining protocols are tailored to preserve Teflon's unique properties.

We ensure your parts are right, from the first prototype to the last high-volume order, by:

- Guaranteeing Stability: We perform controlled thermal annealing on critical components to lock in dimensions and prevent future warping.

- Ensuring Purity: Our rigorous, validated cleaning processes meet the strictest standards for medical, semiconductor, laboratory, and industrial applications.

- Protecting Performance: We use sharp tooling and precise machining parameters to achieve the final low-friction surface finish directly, avoiding any damaging post-processing.

Let us apply our expertise to your most challenging applications.

Contact KINTEB today to discuss your project requirements and receive a quote for precision-machined PTFE seals, liners, labware, and custom components.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments