At its core, the stainless steel spring in a PTFE seal serves as a resilient engine, providing the constant mechanical force required to create and maintain a reliable seal. It energizes the otherwise rigid PTFE jacket, compensates for wear and imperfections, and ensures sealing integrity when system pressure is too low to do the job alone.

The effectiveness of a modern PTFE seal hinges on its stainless steel spring. The spring transforms the low-friction, chemically inert PTFE jacket into a dynamic, resilient sealing element, providing the consistent outward force that PTFE inherently lacks.

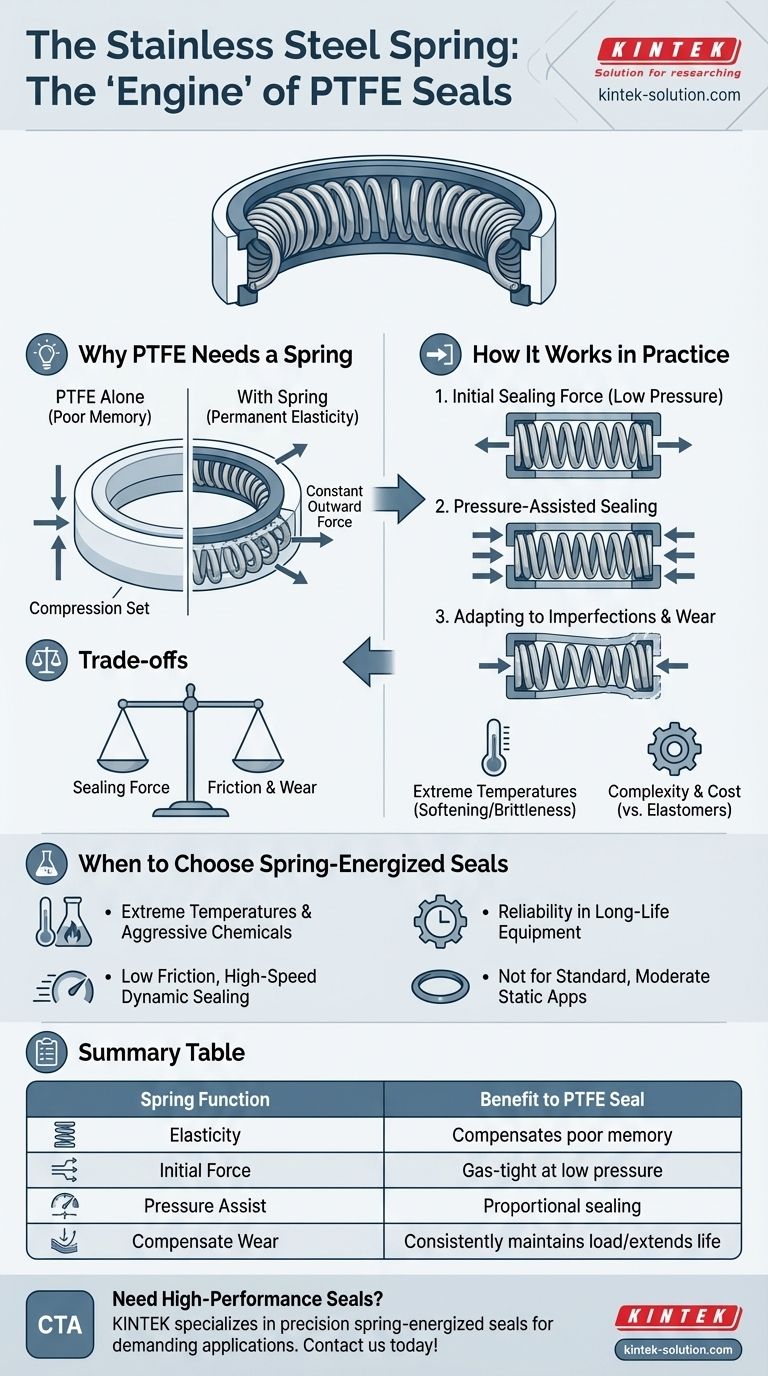

The Core Problem: Why PTFE Needs a Spring

To understand the spring's role, you must first understand the properties of the material it supports: Polytetrafluoroethylene (PTFE).

The Limitation of PTFE Alone

PTFE is an exceptional polymer, known for its extremely low friction, universal chemical resistance, and wide temperature tolerance.

However, it is not an elastomer like rubber. It has poor "memory" and is highly susceptible to compression set, meaning it does not spring back to its original shape after being compressed.

A seal made only of PTFE would quickly lose its sealing force, creating a leak path, especially in dynamic applications or as it wears.

The Spring as the "Engine"

The stainless steel spring solves this problem by providing permanent elasticity.

When the seal is installed, the spring is compressed within the PTFE jacket. It responds with a constant, predictable outward force, pushing the PTFE sealing lips firmly against the mating surfaces.

This spring force is the "engine" that drives the seal's performance, ensuring it remains energized and effective throughout its service life.

How the Spring-Energized Seal Works in Practice

The spring's function is most critical at key stages of operation, from initial installation to long-term performance under pressure.

The Initial Sealing Force

Upon installation into the gland, the seal is compressed. The spring immediately pushes the sealing lips outward to create a gas-tight seal, even before any system pressure is applied.

This initial load is crucial for sealing at zero or very low pressures, where a non-energized seal might fail.

Pressure-Assisted Sealing

As system pressure increases, that pressure acts on the seal, adding to the spring's initial force.

This dynamic enhances the sealing force proportionally to the system pressure, creating an even tighter seal when it's needed most. The spring ensures the seal is already in perfect position to leverage this effect.

Adapting to Imperfections and Wear

No system is perfect. The spring's constant outward push allows the seal to compensate for minor variations in gland tolerances or surface finishes.

More importantly, as the PTFE lips slowly wear down over millions of cycles, the spring expands to take up the gap, maintaining a consistent sealing load and dramatically extending the seal's effective life.

Understanding the Trade-offs

While highly effective, spring-energized seals are a specific solution for demanding applications, and their design involves balancing key factors.

Balancing Sealing Force vs. Friction

The type of spring used (such as a cantilever V-spring or a canted coil spring) directly impacts the force applied to the sealing lips.

A higher spring load creates a more robust seal but also increases friction and potential wear. Engineers must select the right spring to balance sealing requirements with the friction and speed demands of the application.

The Impact of Extreme Temperatures

While the spring itself is stable, the PTFE jacket is the component most affected by temperature.

At very high temperatures, PTFE can soften, and at cryogenic temperatures, it can become brittle. The spring's constant force helps manage these changes, but the ultimate performance window is defined by the thermal limits of the specific PTFE compound used.

Complexity and Cost

A spring-energized seal is a more complex and costly component than a simple O-ring. Its use is justified when an application's demands—such as extreme temperatures, aggressive chemicals, high pressures, or the need for very low friction—exceed the capabilities of conventional elastomeric seals.

Making the Right Choice for Your Application

Use a spring-energized PTFE seal when performance under demanding conditions is non-negotiable.

- If your primary focus is extreme temperatures or aggressive chemicals: Spring-energized seals are ideal, as the design ensures a reliable mechanical seal where elastomers would degrade and fail.

- If your primary focus is low friction and high-speed dynamic sealing: The combination of the spring's precise force and PTFE's slick surface provides superior performance without lubrication.

- If your primary focus is reliability in long-life equipment: The spring’s ability to constantly compensate for wear ensures a more consistent and longer-lasting seal than non-energized alternatives.

- If your primary focus is a standard, static application with moderate conditions: A simpler, less expensive elastomeric seal is often the more practical and cost-effective solution.

Ultimately, the spring is what gives the high-performance PTFE seal its robust, adaptable, and enduring sealing capability.

Summary Table:

| Spring Function | Benefit to PTFE Seal |

|---|---|

| Provides Permanent Elasticity | Compensates for PTFE's poor memory and compression set |

| Creates Initial Sealing Force | Ensures a gas-tight seal at zero or low system pressure |

| Enables Pressure-Assisted Sealing | Enhances sealing force proportionally with system pressure |

| Compensates for Wear & Imperfections | Maintains consistent load, extending seal life |

Need a high-performance seal for demanding conditions?

KINTEK specializes in manufacturing precision PTFE components, including spring-energized seals, for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services ensure you get the perfect seal—from prototypes to high-volume orders—designed to handle extreme temperatures, aggressive chemicals, and provide long-lasting reliability.

Contact us today to discuss your specific sealing requirements and let our experts energize your application with a robust solution.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges