In short, you choose PTFE V-Ring seals for their unmatched reliability in extreme operating conditions. They provide a robust sealing solution where conventional materials would degrade and fail, offering superior chemical resistance, a vast temperature range, and inherently low friction. This makes them essential for mission-critical applications across demanding industries.

The decision to use a PTFE V-Ring is not about a single feature, but about its total value. It represents an investment in operational stability, reducing long-term costs associated with maintenance, downtime, and failure in chemically aggressive or high-temperature environments.

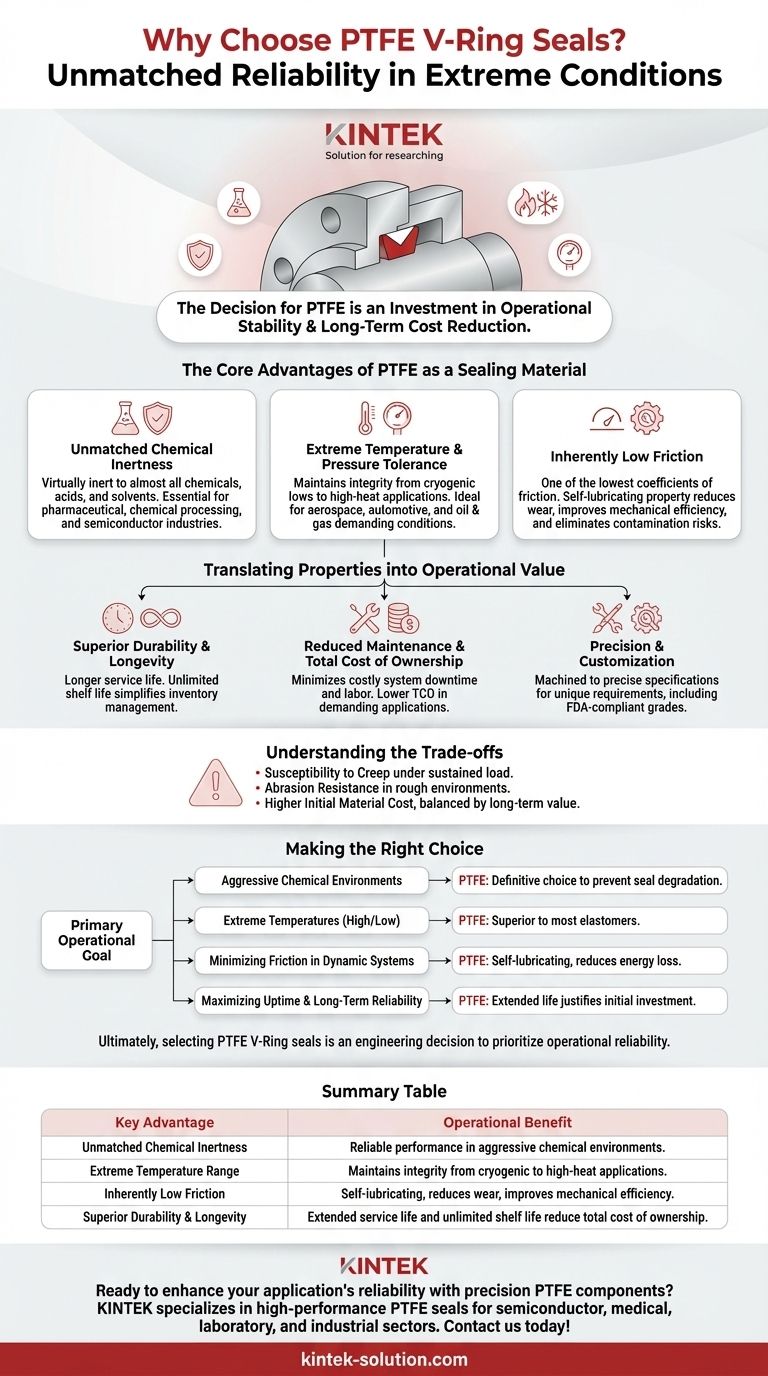

The Core Advantages of PTFE as a Sealing Material

To understand the value of PTFE V-Rings, you must first appreciate the fundamental properties of the material itself. These characteristics are not incremental improvements; they represent a significant leap in performance for specific challenges.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it the default choice for applications involving aggressive media.

This property is critical in industries like pharmaceuticals, chemical processing, and semiconductor manufacturing, where seal integrity in the presence of harsh substances is non-negotiable.

Extreme Temperature and Pressure Tolerance

PTFE seals maintain their integrity and performance across an exceptionally wide temperature range, from cryogenic lows to high-heat applications.

Combined with its ability to handle high pressures, this makes it ideal for the demanding conditions found in the aerospace, automotive, and oil and gas industries.

Inherently Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property is a significant operational advantage.

It reduces wear and tear on moving parts, improves mechanical efficiency by minimizing energy loss, and eliminates the need for external lubricants that could contaminate a system.

Translating Properties into Operational Value

Superior material properties are only valuable when they solve real-world operational problems. This is where PTFE V-Rings provide a clear return on investment.

Superior Durability and Longevity

The combination of chemical, thermal, and environmental resistance (including moisture and UV rays) results in a seal with a significantly longer service life.

These seals do not degrade over time when stored, offering an unlimited shelf life, which simplifies inventory management.

Reduced Maintenance and Total Cost of Ownership

A longer-lasting seal directly translates to lower operating costs. It reduces the frequency of replacement, minimizing labor costs and, more importantly, costly system downtime.

While the initial purchase price may be higher than some alternatives, the total cost of ownership is often far lower in demanding applications.

Precision and Customization

PTFE V-Rings are machined to precise specifications, not molded. This allows for custom designs tailored to unique hardware or specific application requirements.

This manufacturing process also allows for variations, including FDA-compliant grades for food and pharmaceutical use, ensuring the seal perfectly matches the operational need.

Understanding the Trade-offs

No material is perfect for every situation. An objective assessment requires acknowledging the specific limitations of PTFE to ensure it is correctly applied.

Susceptibility to Creep

Under a constant, sustained load, PTFE can be susceptible to "creep" or "cold flow," where the material slowly deforms over time. Modern PTFE compounds often include fillers to significantly improve creep resistance, but it remains a key design consideration.

Abrasion Resistance

Compared to harder polymer or elastomer compounds, pure PTFE can be more vulnerable to abrasive media or rough sealing surfaces. The application environment must be assessed to ensure compatibility.

Cost Consideration

As a high-performance polymer, PTFE typically carries a higher upfront material cost than standard elastomers like Nitrile (Buna-N) or Viton (FKM). Its value is realized in applications where those materials would have a very short service life.

Making the Right Choice for Your Application

Choosing the right seal requires aligning the material's strengths with your primary operational goal.

- If your primary focus is operating in aggressive chemical environments: PTFE is the definitive choice for its near-universal chemical inertness, preventing seal degradation and system failure.

- If your primary focus is performance across extreme temperatures: PTFE's ability to maintain its properties in both high-heat and cryogenic conditions makes it superior to most elastomers.

- If your primary focus is minimizing friction in dynamic systems: PTFE's self-lubricating nature reduces energy loss and component wear, especially where external lubrication is undesirable.

- If your primary focus is maximizing uptime and long-term reliability: The extended service life of PTFE in harsh conditions justifies the initial investment by dramatically reducing maintenance cycles and downtime.

Ultimately, selecting PTFE V-Ring seals is an engineering decision to prioritize operational reliability where system integrity cannot be compromised.

Summary Table:

| Key Advantage | Operational Benefit |

|---|---|

| Unmatched Chemical Inertness | Reliable performance in aggressive chemical environments (acids, solvents). |

| Extreme Temperature Range | Maintains integrity from cryogenic to high-heat applications. |

| Inherently Low Friction | Self-lubricating, reduces wear, and improves mechanical efficiency. |

| Superior Durability & Longevity | Extended service life and unlimited shelf life reduce total cost of ownership. |

Ready to enhance your application's reliability with precision PTFE components?

KINTEK specializes in manufacturing high-performance PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your demanding requirements.

Contact us today to discuss your project and discover how our expertise can provide a robust sealing solution for your mission-critical systems.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions