PTFE ring gaskets are made from Polytetrafluoroethylene, a high-performance synthetic fluoropolymer. This material is renowned for its exceptional chemical resistance, broad temperature tolerance, and extremely low coefficient of friction, making it one of the most versatile sealing materials available.

While PTFE offers elite performance in extreme chemical and thermal environments, its defining characteristic is a trade-off: its unparalleled inertness and lubricity come at the cost of lower mechanical strength compared to other polymers.

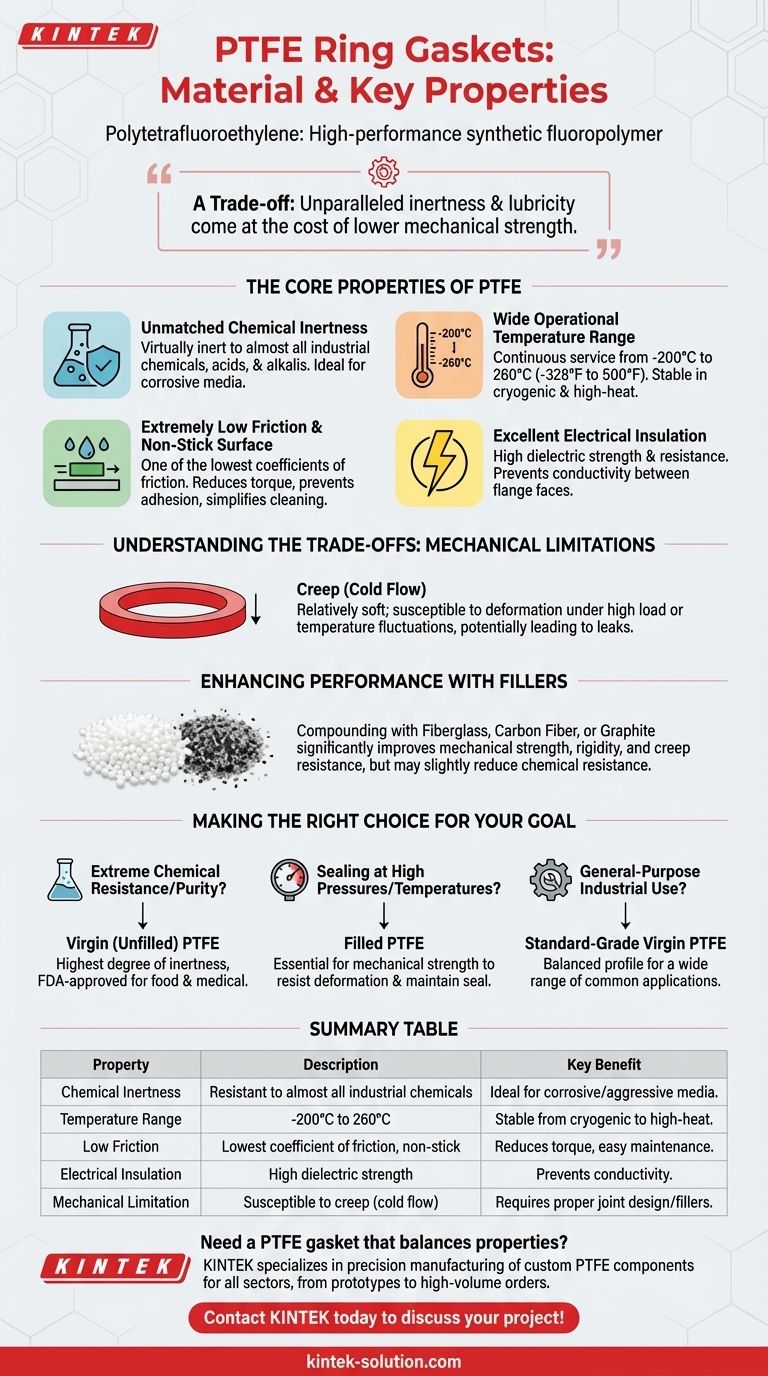

The Core Properties of PTFE

Polytetrafluoroethylene, commonly known by the brand name Teflon, possesses a unique combination of attributes that make it ideal for demanding gasket applications.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, acids, and alkalis. This makes it a default choice for systems handling corrosive or aggressive media where other materials would quickly degrade.

It exhibits broad resistivity to everything from strong acids and organic solvents to bases, ensuring a stable and non-reactive seal.

A Wide Operational Temperature Range

This material maintains its properties across an exceptionally wide thermal spectrum.

Most grades of PTFE can reliably operate in continuous service from approximately -200°C to 260°C (-328°F to 500°F). This stability prevents the gasket from becoming brittle at cryogenic temperatures or degrading in high-heat applications.

Extremely Low Friction and Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material. This inherent lubricity means less torque is required for actuating components like valves.

Its non-stick surface also prevents process media from adhering to the gasket, ensuring purity and simplifying cleaning and maintenance.

Excellent Electrical Insulation

As a material with high dielectric strength and electrical resistance, PTFE is an outstanding electrical insulator. This property is valuable in applications where gaskets must prevent electrical conductivity between flange faces.

Understanding the Trade-offs: Mechanical Limitations

While its chemical and thermal properties are superior, the primary limitation of pure PTFE is its mechanical performance.

Low Mechanical Strength

Compared to other engineering plastics, PTFE is relatively soft. Under high compressive loads, especially over time or with temperature fluctuations, it can be susceptible to creep, also known as "cold flow."

This deformation can lead to a loss of sealing pressure and potential leaks if not accounted for in the joint design.

Enhancing Performance with Fillers

To counteract its mechanical softness, PTFE is often compounded with filler materials.

Adding substances like fiberglass, carbon fiber, or graphite significantly improves the gasket's mechanical strength, rigidity, and resistance to creep. However, these fillers can slightly reduce the material's chemical resistance, introducing a necessary design trade-off.

Making the Right Choice for Your Goal

Selecting the correct type of PTFE gasket is critical for ensuring a long-lasting, reliable seal.

- If your primary focus is extreme chemical resistance or purity: Choose a virgin (unfilled) PTFE gasket, as it offers the highest degree of inertness and is often FDA-approved for food and medical use.

- If your primary focus is sealing at high pressures or temperatures: A filled PTFE gasket is essential to provide the mechanical strength needed to resist deformation and maintain a tight seal.

- If your primary focus is general-purpose industrial use: A standard-grade virgin PTFE gasket provides a balanced profile of performance for a wide range of common applications.

Understanding these core properties and limitations ensures you select a gasket that performs as a reliable seal, not a future point of failure.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resistant to almost all industrial chemicals, acids, and alkalis. | Ideal for corrosive or aggressive media. |

| Temperature Range | Operates from -200°C to 260°C (-328°F to 500°F). | Stable performance from cryogenic to high-heat. |

| Low Friction | One of the lowest coefficients of friction of any solid. | Reduces actuation torque, non-stick surface. |

| Electrical Insulation | High dielectric strength and electrical resistance. | Prevents conductivity between flange faces. |

| Mechanical Limitation | Susceptible to creep (cold flow) under high load. | Requires proper joint design or filled grades. |

Need a PTFE gasket that perfectly balances chemical resistance, temperature stability, and mechanical strength?

At KINTEK, we specialize in precision manufacturing of PTFE components, including seals, liners, and labware. Whether your application is in the semiconductor, medical, laboratory, or industrial sector, we provide custom fabrication from prototypes to high-volume orders. Our expertise ensures you get a gasket solution tailored to your specific environmental demands and performance requirements.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts