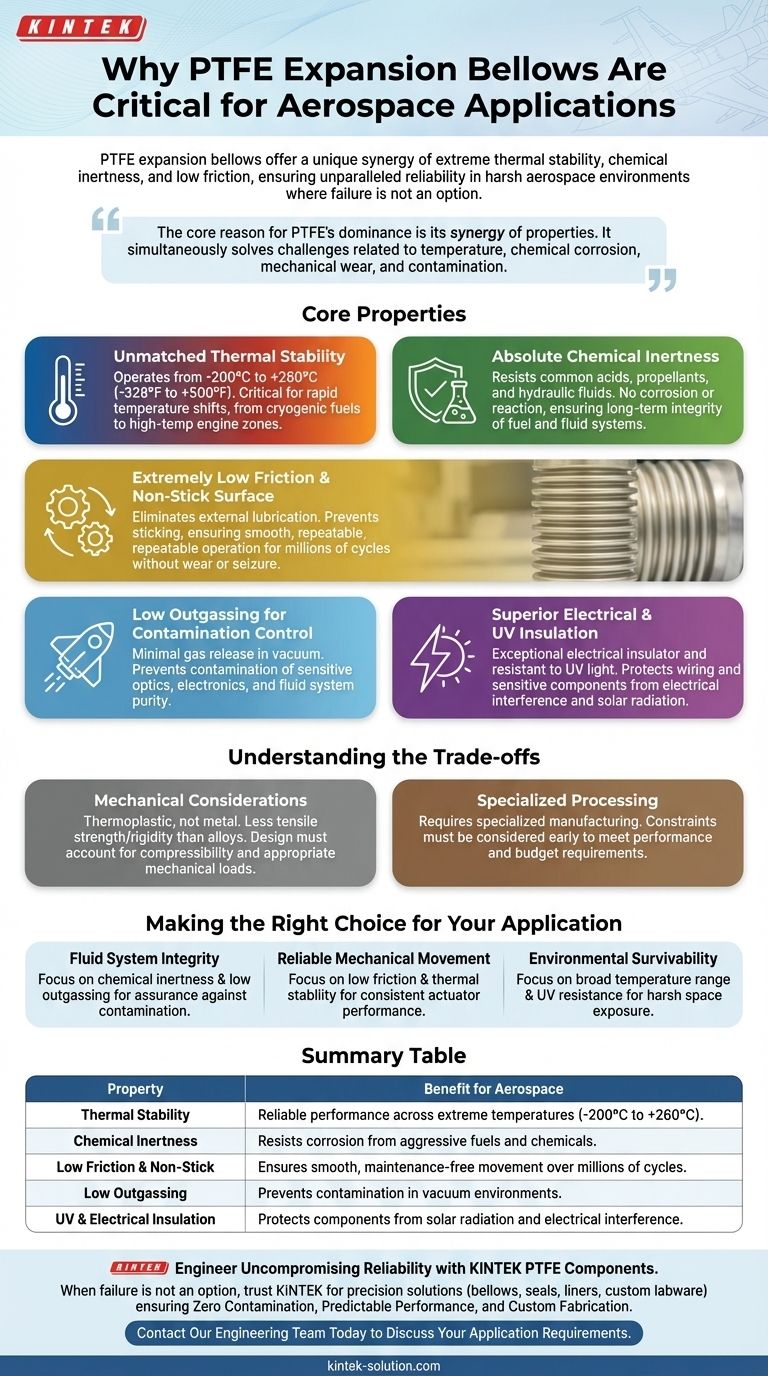

In short, PTFE expansion bellows are suitable for aerospace applications because they offer a rare combination of extreme thermal stability, complete chemical inertness, and low friction. These properties ensure unparalleled reliability in the harsh and unforgiving environments of aviation and space, where component failure is not an option.

The core reason for PTFE's dominance in aerospace is not a single feature, but its unique synergy of material properties. It simultaneously solves challenges related to temperature, chemical corrosion, mechanical wear, and system contamination that few other materials can address at once.

The Core Properties Driving Aerospace Adoption

To understand why PTFE is a go-to material for critical aerospace components like expansion bellows, we must examine the specific properties that directly counter the extreme challenges of flight and space operations.

Unmatched Thermal Stability

PTFE is the most thermally-stable plastic, capable of performing reliably in temperatures ranging from -200°C to +260°C (-328°F to +500°F).

This enormous operational window is critical for aerospace systems that experience rapid and extreme temperature shifts, from cryogenic fuel exposure to high-temperature engine environments.

Absolute Chemical Inertness

PTFE is highly resistant to virtually all common chemicals, acids, and aggressive propellants used in aerospace, including hydraulic fluids and rocket fuel.

This inertness guarantees that the bellow will not corrode, degrade, or react with the fluids it contains or is exposed to, ensuring the long-term integrity of fuel and fluid transfer systems.

Extremely Low Friction and Non-Stick Surface

Among all plastics, PTFE has one of the lowest coefficients of friction, eliminating the need for external lubrication. Its anti-adhesive properties prevent sticking.

For an expansion bellow, which must constantly flex and move, this ensures smooth, predictable, and repeatable operation over millions of cycles without wear or seizure, which is vital for components like actuators.

Low Outgassing for Contamination Control

PTFE has very low outgassing properties, meaning it does not release trapped gases when exposed to the vacuum of space or high temperatures.

This is a critical requirement for aerospace, as outgassed molecules can contaminate sensitive optics, interfere with electronics, or compromise the purity of fluid systems.

Superior Electrical and UV Insulation

The material is an exceptional electrical insulator and is highly resistant to UV light.

This makes PTFE bellows effective as protective conduits for wiring and sensitive components, shielding them from electrical interference and the degrading effects of solar radiation in space.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. Understanding its limitations is key to proper engineering design in an aerospace context.

Mechanical Considerations

PTFE is a thermoplastic, not a metal. While it has excellent dimensional stability and creep resistance for a polymer, it does not possess the high tensile strength or rigidity of steel or titanium alloys.

Designers must account for its compressibility and ensure the mechanical loads of the system are appropriate for the material's specifications to prevent deformation.

Specialized Processing

Fabricating complex PTFE components requires specialized manufacturing techniques. This can influence design possibilities and cost compared to more traditional materials.

Engineers must consider these manufacturing constraints early in the design phase to ensure the final part meets all performance and budgetary requirements.

Making the Right Choice for Your Application

Selecting PTFE bellows should be a decision driven by the specific demands of the aerospace system.

- If your primary focus is fluid system integrity: PTFE's chemical inertness and low outgassing provide the highest assurance against contamination and corrosion.

- If your primary focus is reliable mechanical movement: Its low friction and extreme temperature stability ensure consistent performance in actuators and flexible joints.

- If your primary focus is environmental survivability: The material's broad temperature range and UV resistance make it ideal for components exposed to the harshness of space.

Ultimately, choosing PTFE is a commitment to operational reliability in environments where failure has catastrophic consequences.

Summary Table:

| Property | Benefit for Aerospace |

|---|---|

| Thermal Stability (-200°C to +260°C) | Reliable performance from cryogenic fuels to high-temp engine zones. |

| Chemical Inertness | Resists corrosion from fuels, hydraulic fluids, and aggressive chemicals. |

| Low Friction & Non-Stick | Ensures smooth, maintenance-free movement in actuators over millions of cycles. |

| Low Outgassing | Prevents contamination of sensitive optics and electronics in vacuum environments. |

| UV & Electrical Insulation | Protects wiring and components from solar radiation and electrical interference. |

Engineer Uncompromising Reliability with KINTEK PTFE Components

When failure is not an option, trust KINTEK to deliver precision PTFE solutions that meet the extreme demands of aerospace, medical, and semiconductor industries. Our expansion bellows, seals, liners, and custom labware are manufactured to ensure:

- Zero Contamination: Guarantee the purity of critical fluid and fuel systems with our chemically inert, low-outgassing components.

- Predictable Performance: Achieve consistent, long-term operation in temperatures from -200°C to +260°C.

- Custom Fabrication: From initial prototypes to high-volume production, we work with you to design and manufacture components tailored to your exact specifications.

Ready to specify components that withstand the toughest environments? Contact our engineering team today to discuss your application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials