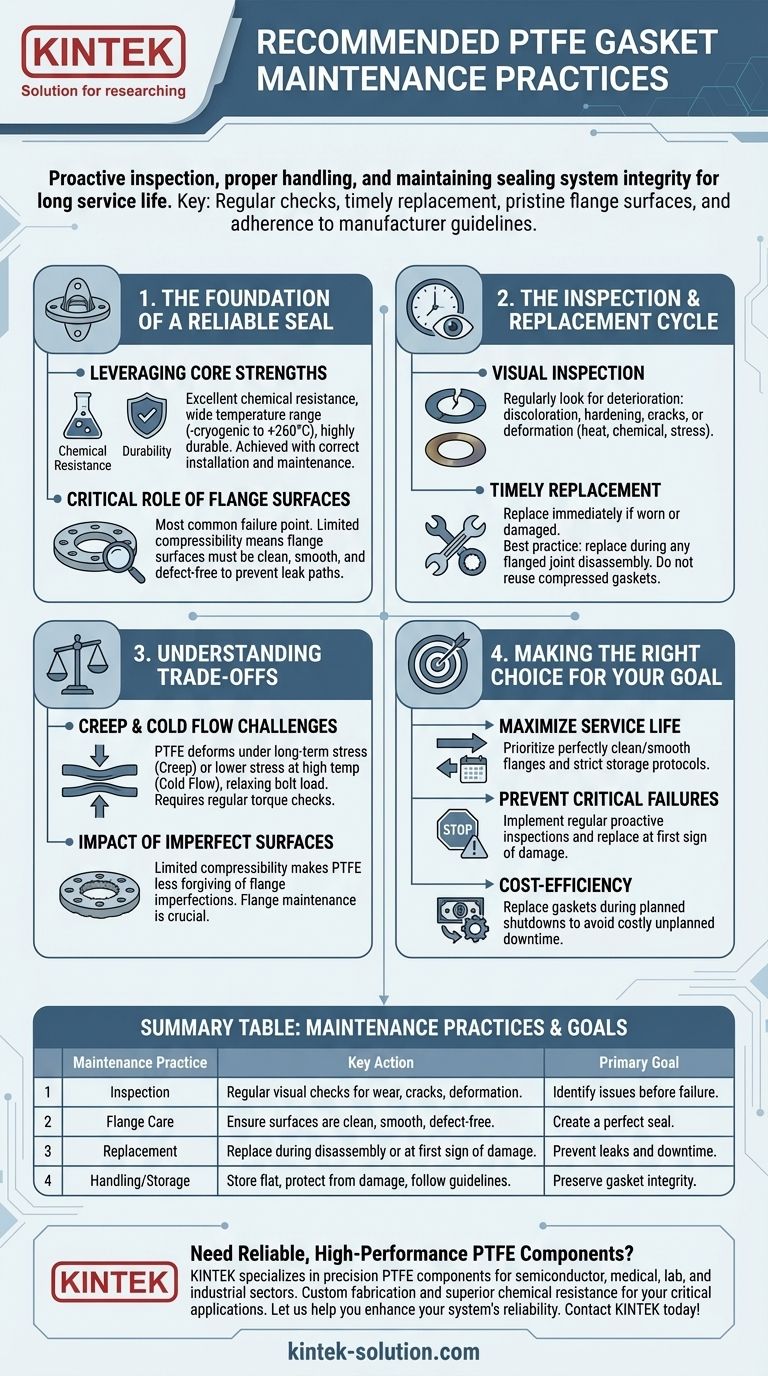

The recommended maintenance practices for PTFE gaskets center on proactive inspection, proper handling, and maintaining the integrity of the entire sealing system. This involves regularly checking for wear, replacing gaskets before they fail, ensuring flange surfaces are pristine, and adhering to manufacturer guidelines for storage and installation to maximize their long service life.

While PTFE gaskets are exceptionally durable and low-maintenance, their reliability hinges on understanding and mitigating their primary limitations: a tendency to deform under pressure (creep) and an inability to compensate for imperfect surfaces.

The Foundation of a Reliable Seal

To properly maintain a PTFE gasket, you must first understand the environment it needs to succeed. The gasket itself is only one part of a system that must work in harmony.

Leveraging PTFE's Core Strengths

Polytetrafluoroethylene (PTFE) is chosen for its remarkable properties. It has outstanding chemical resistance, performs across a wide temperature range (from cryogenic to +260°C), and is highly durable even in harsh conditions.

These characteristics give PTFE gaskets a long product life, but this longevity is not guaranteed. It is achieved only when the gasket is installed and maintained correctly.

The Critical Role of Flange Surfaces

The most common point of failure is not the gasket material itself, but the surface it seals against. PTFE has limited compressibility compared to softer materials, meaning it cannot easily fill deep scratches, gouges, or warped areas on a flange.

Therefore, a core maintenance practice is to keep flange surfaces clean, smooth, and free of defects. Any imperfection creates a potential leak path.

Proper Storage and Handling

Maintenance begins before installation. Gaskets should be stored flat and protected from dirt, moisture, and physical damage according to the manufacturer's guidelines.

A small nick or crease acquired during storage or handling can compromise the seal once it's put into service under pressure.

The Inspection and Replacement Cycle

Proactive maintenance is about identifying potential issues before they lead to a system failure. This requires a disciplined approach to inspection and replacement.

What to Look For During Inspection

Regular visual inspection is essential. Look for clear signs of deterioration or damage.

Key indicators include discoloration, hardening, cracks, or any visible deformation. These signs suggest the gasket has been compromised by heat, chemical attack, or excessive stress.

Understanding When to Replace

The goal is timely replacement, not replacement after failure. If a gasket shows any signs of wear or damage, it should be replaced immediately.

It is also best practice to replace gaskets whenever a flanged joint is disassembled for other maintenance. PTFE gaskets, once compressed, conform to a specific surface and are not designed to be reused.

Understanding the Trade-offs of PTFE

No material is perfect. Acknowledging the inherent limitations of PTFE is critical for effective maintenance and preventing common failures.

The Challenge of Creep and Cold Flow

PTFE's primary weakness is its tendency to deform over time.

- Creep is the gradual deformation of the material under long-term stress, such as the constant pressure from bolt torque.

- Cold Flow is the tendency to deform under lower stress, particularly at elevated temperatures.

Both phenomena can cause the bolt load to relax, reducing the sealing pressure and eventually leading to a leak. Regular torque checks and replacement are the primary countermeasures.

The Impact of Imperfect Sealing Surfaces

As noted, PTFE's limited compressibility is a key trade-off. While it creates a firm, durable seal on a perfect surface, it makes the gasket less forgiving of flange imperfections.

This reinforces the fact that maintaining the flange is just as important as maintaining the gasket itself.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your operational priorities. A few simple rules can ensure you achieve maximum reliability and service life from your PTFE gaskets.

- If your primary focus is maximizing service life: Prioritize maintaining perfectly clean and smooth flange surfaces and adhere strictly to proper storage protocols.

- If your primary focus is preventing critical failures: Implement a schedule of regular, proactive inspections and replace gaskets at the first sign of deformation or damage.

- If your primary focus is cost-efficiency: Understand that the cost of a failed gasket is far greater than the cost of a new one. Replace gaskets during any planned system shutdown to avoid costly unplanned downtime.

By treating the gasket as part of a complete sealing system, you can turn maintenance from a reactive task into a powerful strategy for ensuring operational reliability.

Summary Table:

| Maintenance Practice | Key Action | Primary Goal |

|---|---|---|

| Inspection | Regular visual checks for wear, cracks, or deformation. | Identify issues before failure. |

| Flange Care | Ensure surfaces are clean, smooth, and defect-free. | Create a perfect seal. |

| Replacement | Replace during disassembly or at first sign of damage. | Prevent leaks and downtime. |

| Handling/Storage | Store flat, protect from damage, follow manufacturer guidelines. | Preserve gasket integrity pre-installation. |

Need Reliable, High-Performance PTFE Components?

Proper maintenance starts with a quality gasket. KINTEK specializes in manufacturing precision PTFE components—including seals, gaskets, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and superior chemical resistance for your critical applications.

Let us help you enhance your system's reliability. Contact KINTEK today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions