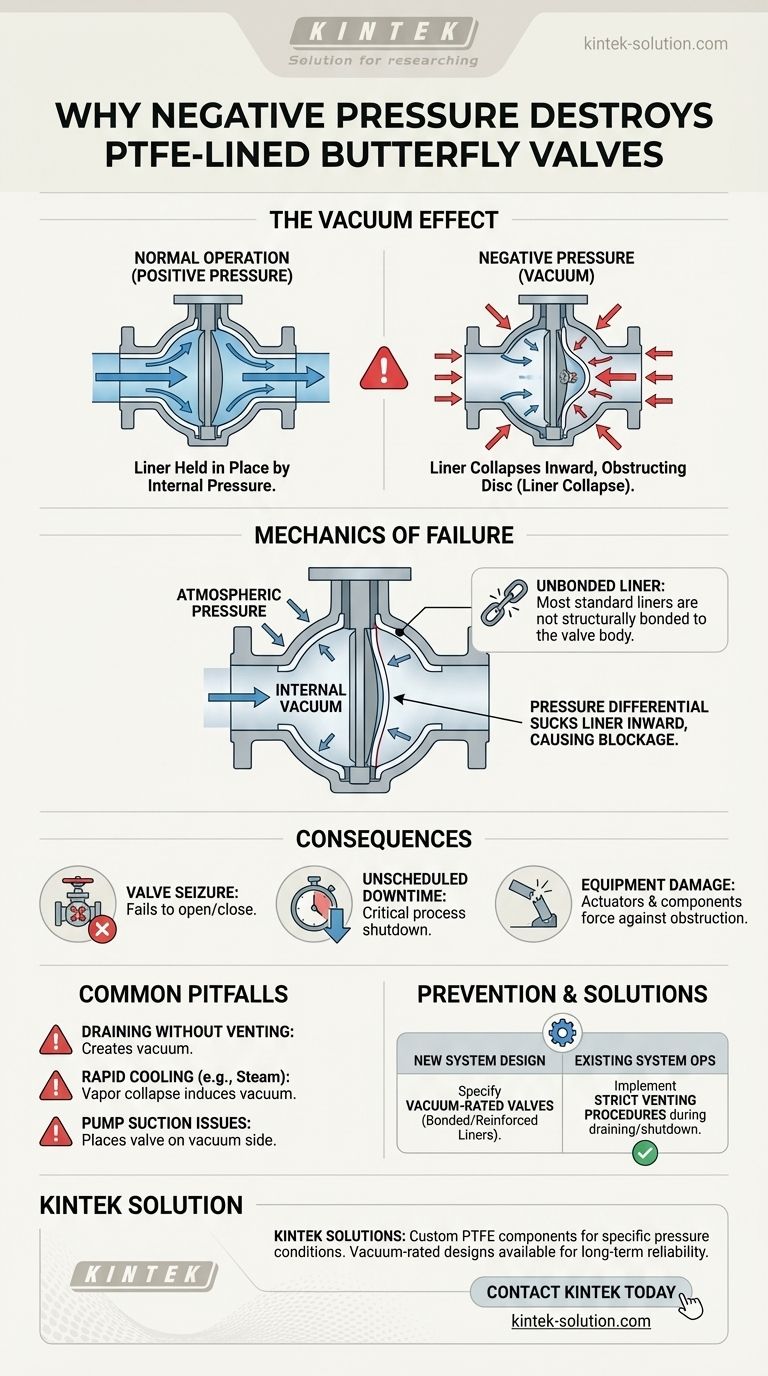

Under no circumstances should a standard PTFE-lined butterfly valve be subjected to negative pressure or vacuum conditions. Doing so creates a high risk of catastrophic failure, where the vacuum effect pulls the liner inward and away from the valve body. This event, known as liner collapse, will obstruct the valve disc, cause it to seize, and render it inoperable.

The core issue is that most PTFE liners are not structurally bonded to the valve's metal body. Negative pressure creates a pressure differential that physically sucks the flexible liner into the pipeline, causing an immediate mechanical blockage and valve failure.

The Mechanics of Liner Failure Under Vacuum

To prevent this failure, it is essential to understand how a seemingly small amount of negative pressure can destroy the valve from the inside out.

The Role of the PTFE Liner

A PTFE (polytetrafluoroethylene) liner provides exceptional corrosion resistance against a wide range of aggressive chemicals. It is fitted into the valve body to isolate the process media from the metal components.

In many standard designs, this liner is held in place by mechanical compression and is not fully bonded to the valve body across its entire surface.

The Vacuum Effect Explained

Negative pressure, or a vacuum, means the pressure inside the pipe is lower than the atmospheric pressure outside the valve. This creates a powerful pressure differential.

This differential exerts a force on the liner, pulling it inward toward the center of the pipe. Because the liner is not rigidly attached, it can easily delaminate, buckle, or be "sucked out" of its housing.

The Consequences of Liner Collapse

When the liner collapses, it bulges into the flow path and physically obstructs the valve's disc.

This leads to several immediate problems:

- The valve will fail to close or open, effectively seizing in its current position.

- Automated actuators may be damaged as they attempt to force the disc past the obstruction.

- The entire process line is forced into an unscheduled and often critical shutdown.

Understanding the Broader Risk: Pressure Differentials

The vulnerability of PTFE-lined valves is not limited to just negative pressure. It is a function of their sensitivity to excessive pressure differentials in general.

Negative Pressure as a Differential Force

A vacuum is simply one type of pressure differential—where the external pressure is greater than the internal pressure. The liner is not designed to withstand this external compressive force.

The Risk to Other PTFE Components

This same principle applies to other valve components made from PTFE, such as bellows in specialty valves. An excessive pressure difference, whether positive or negative, can cause these flexible components to rupture or deform.

Controlling pressure within the manufacturer's specified range is crucial for maintaining the mechanical integrity of any valve with non-metallic seals or liners.

Common Pitfalls and Operational Risks

Liner collapse is almost always preventable, as it typically results from operational oversight or system design flaws.

Unintentional Vacuum Conditions

Engineers and operators must be aware of common scenarios that can induce a vacuum in a pipeline:

- Draining a line without providing adequate air venting.

- Rapid cooling of a condensable vapor (like steam), causing it to collapse into a liquid and create a strong vacuum.

- Pump suction issues or shutoffs that place the valve on the vacuum side of a process.

Misapplication of Standard Valves

A critical mistake is specifying a standard PTFE-lined valve for a service where vacuum conditions are known to occur, even intermittently. These applications demand specially designed equipment.

Making the Right Choice for Your System

Protecting your system requires a proactive approach based on its specific operational parameters.

- If your primary focus is designing a new system: Always verify that operational or shutdown procedures will not create a vacuum. If vacuum conditions are unavoidable, you must specify a vacuum-rated valve, which may feature a more robust, thicker, or bonded liner.

- If your primary focus is operating an existing system: Implement strict procedures for venting pipelines during draining and shutdown. Ensure all operators understand that inducing a vacuum poses a direct threat to valve integrity.

- If your primary focus is maintenance and reliability: When a PTFE-lined valve fails, investigate the possibility of vacuum as the root cause before simply replacing the unit. A repeat failure is likely if the underlying system conditions are not addressed.

Proactively managing pressure dynamics is the key to ensuring the long-term reliability of any system utilizing PTFE-lined components.

Summary Table:

| Risk Factor | Consequence | Prevention |

|---|---|---|

| Negative Pressure (Vacuum) | Liner collapses inward, obstructing disc | Use vacuum-rated valves; ensure proper venting |

| Unbonded PTFE Liner | Liner delaminates from valve body under pressure differential | Specify valves with bonded or reinforced liners |

| Unintentional Vacuum (e.g., from draining, rapid cooling) | Valve seizure, actuator damage, unplanned downtime | Implement strict operational procedures |

Don't let liner collapse shut down your process.

At KINTEK, we understand the critical need for reliable PTFE components in demanding environments. For semiconductor, medical, laboratory, and industrial applications, our custom-fabricated PTFE seals, liners, and labware are engineered for performance under specific pressure conditions, including vacuum-rated designs.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today to discuss your application requirements and ensure your valves and components are built to last.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications