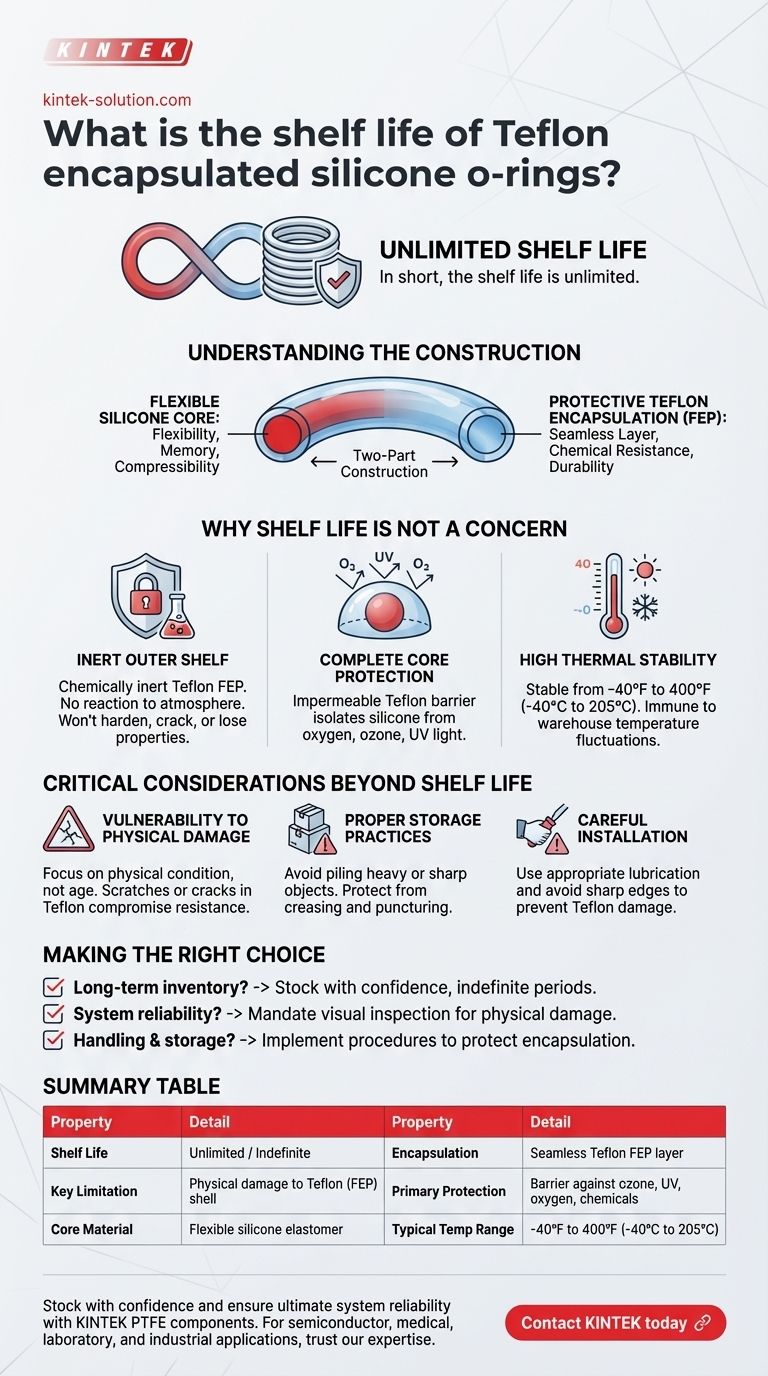

In short, the shelf life is unlimited. Teflon (FEP) encapsulated silicone o-rings do not have a defined expiration date because their materials are exceptionally stable. The outer Teflon shell protects the inner silicone core from environmental factors like ozone, UV radiation, and oxygen that typically degrade standard elastomeric seals over time.

The key takeaway is that for encapsulated o-rings, the primary concern is not material degradation from age, but physical damage to the Teflon shell during storage or installation. Their chemical inertness grants them an indefinite shelf life.

Understanding the Construction

The unique properties of these o-rings stem directly from their two-part construction. This design combines the best qualities of two different materials into a single, high-performance seal.

The Flexible Silicone Core

The inner core is made of silicone elastomer. This material provides the o-ring with its flexibility, memory, and compressibility, allowing it to conform to sealing surfaces effectively.

The Protective Teflon Encapsulation

This silicone core is completely enclosed in a seamless layer of Teflon FEP (Fluorinated Ethylene Propylene). This outer shell is what provides the o-ring's exceptional chemical resistance and durability.

Why Shelf Life Is Not a Concern

Unlike standard rubber o-rings that have a limited shelf life defined by standards like ARP5316, encapsulated o-rings are exempt from these concerns due to the nature of their protective shell.

Inert Outer Shell

The Teflon FEP encapsulation is chemically inert. It does not react with or degrade from exposure to atmospheric conditions, meaning it won't harden, crack, or lose its properties simply by sitting on a shelf.

Complete Core Protection

The seamless Teflon layer acts as an impermeable barrier. It completely isolates the inner silicone core from oxygen, ozone, and UV light, which are the primary causes of aging and degradation in standard elastomers.

High Thermal Stability

These o-rings are stable across a very wide temperature range, typically from -40ºF up to 400ºF (-40ºC to 205ºC). This stability ensures that typical warehouse temperature fluctuations will have no impact on the material's integrity during long-term storage.

Critical Considerations Beyond Shelf Life

While time is not a factor, these o-rings are not indestructible. The focus of quality control must shift from age to physical condition.

Vulnerability to Physical Damage

The primary failure mode is physical damage to the thin Teflon encapsulation. A scratch, nick, or crack in the outer shell can compromise the o-ring's chemical resistance, exposing the vulnerable silicone core.

Proper Storage Practices

Although their shelf life is unlimited, they must be stored properly. Avoid piling heavy objects on them or storing them with sharp items that could puncture or crease the encapsulation. Proper storage prevents physical damage, not chemical degradation.

Careful Installation

Extra care is required during installation to avoid damaging the Teflon surface. Using appropriate lubrication and avoiding sharp edges in the gland or on tools is critical to ensuring a reliable seal.

Making the Right Choice for Your Application

Focusing on the correct parameters is key to leveraging the benefits of these components.

- If your primary focus is long-term inventory: You can confidently stock these o-rings for indefinite periods without concern for material expiration, simplifying logistics and reducing waste.

- If your primary focus is system reliability: Mandate a thorough visual inspection for any physical damage to the Teflon shell before installation, as this is the most critical factor for performance.

- If your primary focus is handling and storage: Implement procedures that protect the o-rings from being crushed, creased, or cut to maintain the integrity of their protective encapsulation.

Ultimately, the unlimited shelf life of these o-rings offers a significant logistical advantage, provided they are handled with care to protect their physical structure.

Summary Table:

| Property | Detail |

|---|---|

| Shelf Life | Unlimited / Indefinite |

| Key Limitation | Physical damage to the Teflon (FEP) shell |

| Core Material | Flexible silicone elastomer |

| Encapsulation | Seamless Teflon FEP layer |

| Primary Protection | Barrier against ozone, UV, oxygen, and chemicals |

| Typical Temperature Range | -40°F to 400°F (-40°C to 205°C) |

Stock with confidence and ensure ultimate system reliability with KINTEK PTFE components.

Our precision-manufactured Teflon encapsulated o-rings provide the indefinite shelf life you need for efficient inventory management, eliminating material expiration concerns. For semiconductor, medical, laboratory, and industrial applications where chemical resistance and long-term reliability are non-negotiable, trust our expertise in custom fabrication—from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific sealing requirements and leverage our material science expertise for your most demanding applications.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are some common PTFE seal types used in industrial applications? Explore Solutions for Every Motion & Environment

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance