The continuous arrival of new PTFE gasket products is driven by the need to solve the inherent mechanical weaknesses of traditional PTFE. While standard PTFE offers elite chemical and temperature resistance, it suffers from "creep" or cold flow under pressure. New, innovative gaskets are engineered with fillers and advanced manufacturing processes specifically to overcome this critical flaw and enhance sealing reliability.

The market isn't just creating more of the same; it's engineering solutions to PTFE's core mechanical weaknesses. New gaskets combine PTFE's legendary chemical inertness with advanced structures and fillers to create stronger, more reliable seals for today's demanding industrial applications.

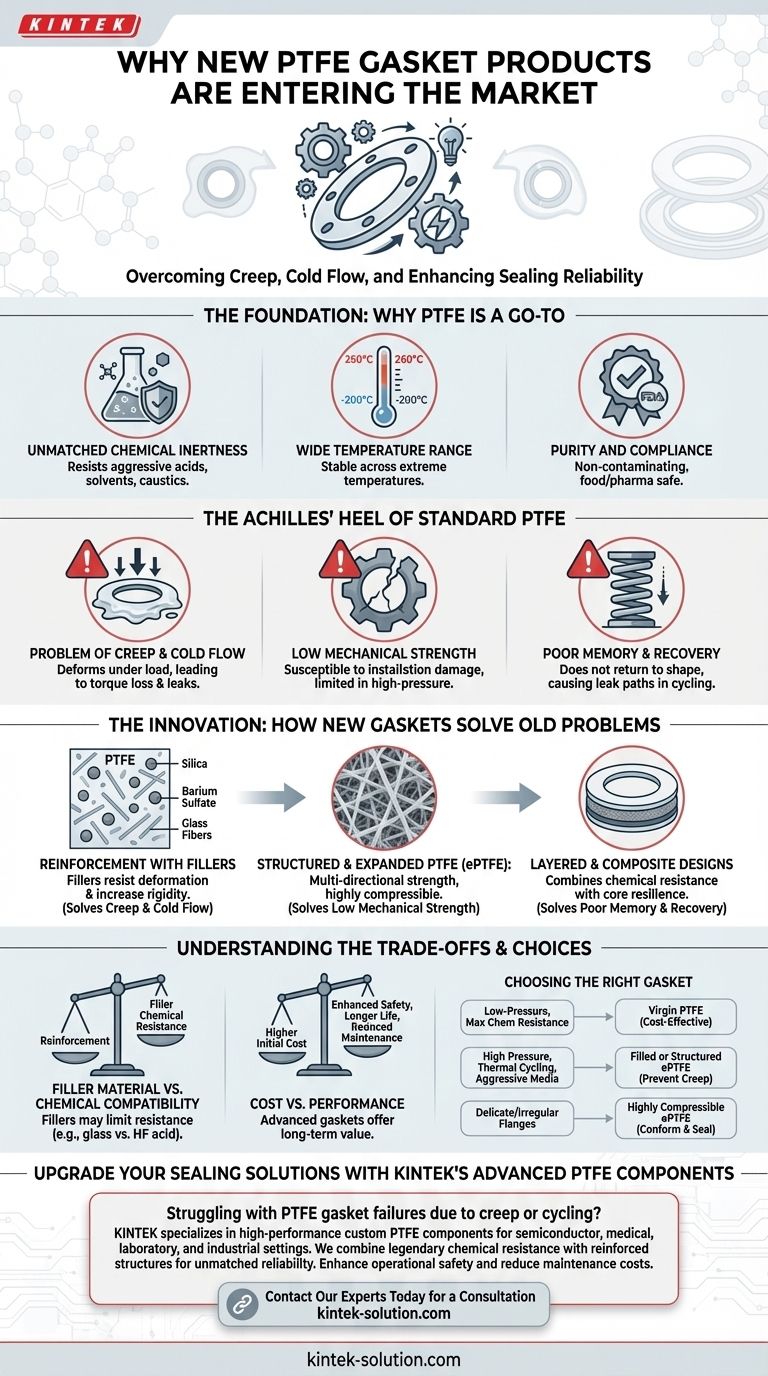

The Foundation: Why PTFE is a Go-To Sealing Material

To understand the innovation, we must first appreciate the baseline advantages of Polytetrafluoroethylene (PTFE). For decades, it has been a default choice in many industries for several key reasons.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals. This makes it an essential material for applications involving aggressive acids, solvents, or caustic substances where other elastomers would rapidly degrade.

Wide Temperature Range

The material maintains its properties across an exceptionally broad temperature spectrum, from cryogenic lows (-200°C) to high heat (260°C). This versatility allows it to be specified in a vast number of processes without concern for thermal breakdown.

Purity and Compliance

PTFE is inherently non-contaminating and can comply with strict regulatory standards, including FDA requirements for food and pharmaceutical contact. This ensures product purity, a non-negotiable factor in sanitary applications.

Addressing the Achilles' Heel of Standard PTFE

Despite its chemical superiority, pure, unfilled PTFE has significant mechanical limitations that new products are designed to solve. These weaknesses can lead to seal failure in demanding conditions.

The Problem of Creep and Cold Flow

This is the single most critical weakness of standard PTFE. When subjected to the compressive load from flange bolts, the material slowly "flows" or deforms away from the pressure point. This causes a loss of bolt torque, reduces sealing stress, and can ultimately result in a leak.

Low Mechanical Strength

Pure PTFE is a relatively soft material. This makes it susceptible to damage during installation and limits its use in high-pressure services where a more robust material is required to maintain integrity.

Poor Memory and Recovery

Once compressed, standard PTFE does not "spring back" to its original shape effectively. In services with pressure or temperature cycles, this lack of recovery can create leak paths as the flange faces expand and contract.

The Innovation: How New Gaskets Solve Old Problems

The new generation of PTFE gaskets directly targets the mechanical flaws of creep, low strength, and poor recovery through sophisticated engineering and material science.

Reinforcement with Fillers

The most common innovation is the addition of filler materials to the PTFE matrix. Fillers like silica, barium sulfate, or milled glass fibers are blended in to create a composite material. These fillers act as a reinforcing structure, drastically reducing creep and increasing the gasket's rigidity and load-bearing capability.

Structured and Expanded PTFE (ePTFE)

Instead of just adding fillers, some manufacturing processes alter the physical structure of the PTFE itself. Expanded PTFE (ePTFE) is created by introducing a porous, multi-directionally strong fibrous structure. This structure provides excellent strength and resists creep while remaining highly compressible, making it ideal for creating a tight seal with less bolt force.

Layered and Composite Designs

Another approach involves using PTFE as one component in a multi-layered gasket. This might include a PTFE envelope over a more resilient core material, combining the chemical resistance of PTFE on the wetted surfaces with the mechanical strength and recovery of the core.

Understanding the Trade-offs

While engineered PTFE gaskets offer superior performance, selecting them requires an understanding of the compromises involved.

Filler Material vs. Chemical Compatibility

Adding a filler can slightly compromise PTFE's near-universal chemical resistance. For example, a glass-filled gasket may not be suitable for service with hydrofluoric acid or strong alkalis that can attack the glass filler. The base PTFE remains unaffected, but the filler can be a point of failure.

Cost vs. Performance

Advanced, filled, or structured PTFE gaskets are more expensive than simple, die-cut virgin PTFE sheets. The higher initial cost is justified by enhanced safety, longer service life, and reduced maintenance costs associated with preventing leaks and re-torquing flanges.

The Importance of Proper Installation

No gasket technology can compensate for improper installation. Even the most advanced ePTFE gasket requires clean, undamaged flange surfaces and the correct, evenly applied bolt load to function as designed.

Choosing the Right PTFE Gasket for Your Application

Your final choice depends entirely on the specific demands of the service environment.

- If your primary focus is maximum chemical resistance in low-pressure systems: A pure, virgin PTFE gasket is often sufficient and cost-effective.

- If you are dealing with high pressure, thermal cycling, or aggressive media: A filled or structured ePTFE gasket is necessary to prevent creep and maintain a reliable, long-term seal.

- If you need to seal delicate or irregular flanges (e.g., glass-lined steel): Look for highly compressible ePTFE gaskets that can conform to surfaces and create a seal with lower bolt loads.

Understanding this evolution from a simple material to an engineered solution empowers you to select a gasket that provides not just compatibility, but long-term operational reliability.

Summary Table:

| Problem with Standard PTFE | Solution with New PTFE Gaskets |

|---|---|

| Creep & Cold Flow | Filled composites (e.g., silica, glass) resist deformation |

| Low Mechanical Strength | Expanded PTFE (ePTFE) provides multi-directional strength |

| Poor Memory & Recovery | Layered designs enhance resilience and sealing under cycling |

| Limited High-Pressure Use | Engineered structures maintain integrity under high loads |

Upgrade Your Sealing Solutions with KINTEK's Advanced PTFE Components

Are you struggling with PTFE gasket failures due to creep, cold flow, or pressure cycling? KINTEK specializes in manufacturing high-performance PTFE components—including seals, liners, and labware—engineered to overcome these exact challenges. Our custom fabrication process, from prototypes to high-volume orders, ensures you get a sealing solution tailored to your specific application in semiconductor, medical, laboratory, or industrial settings. We combine PTFE's legendary chemical resistance with reinforced structures for unmatched reliability.

Let us help you enhance operational safety and reduce maintenance costs. Contact our experts today for a consultation on your sealing needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries