Selecting the right PTFE gasket is a systematic process of matching the material to your precise operational conditions. The choice depends on a careful evaluation of your application's temperature, pressure, chemical environment, and mechanical demands, which dictates the specific type of PTFE—virgin, filled, or expanded—and its required dimensions.

The most common failure in PTFE gaskets comes from overlooking its primary weakness: creep, or cold flow. Your selection process must therefore focus not just on PTFE's well-known chemical resistance, but on choosing a specific grade and form factor engineered to resist the mechanical and thermal stresses of your system.

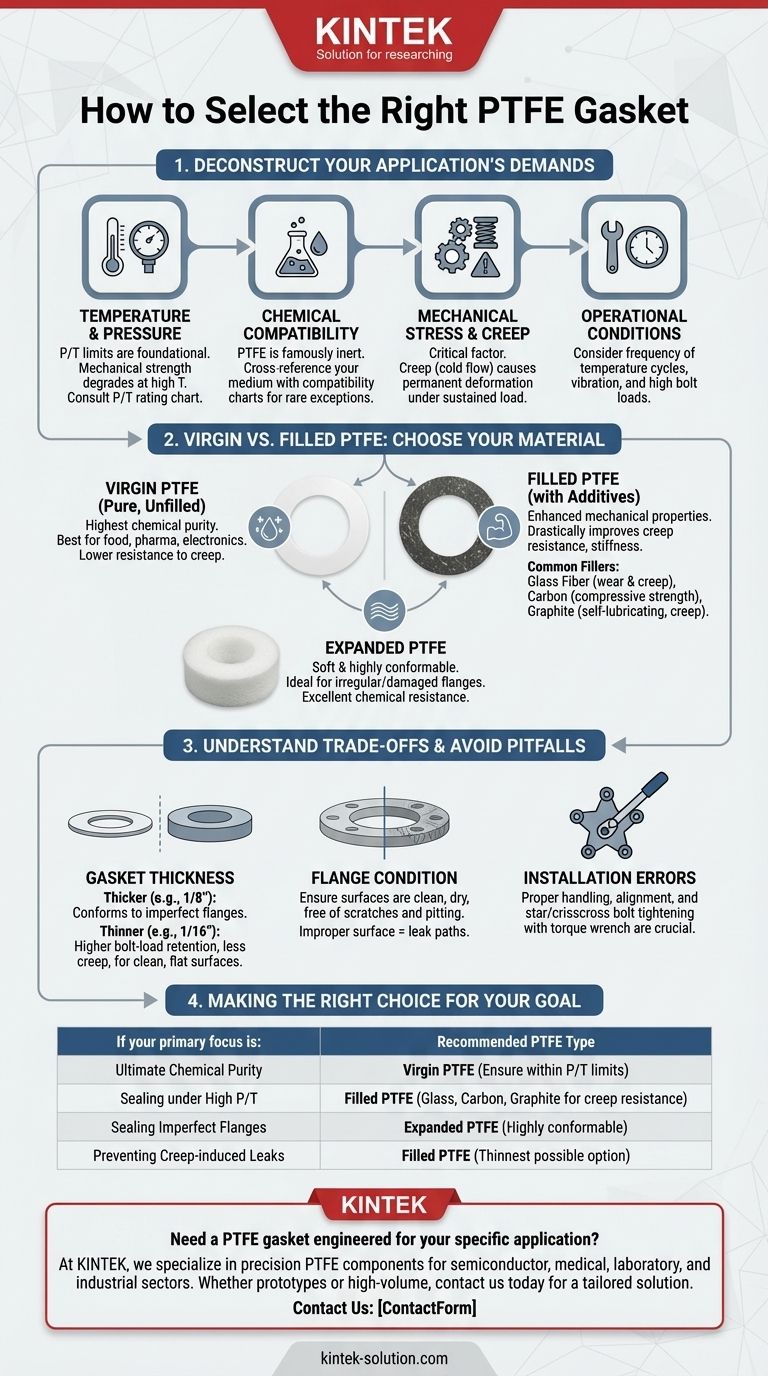

Deconstructing Your Application's Demands

Before looking at any gasket, you must first quantify the environment where it will operate. A gasket is a component of a larger system, and its success depends entirely on its suitability for that system.

Temperature and Pressure Limits

Temperature and pressure are the foundational gatekeepers for gasket selection. PTFE is known for its wide operating temperature range, but its mechanical strength degrades at higher temperatures.

High pressure exacerbates this issue. A gasket that performs well at ambient temperature may fail under high pressure as the temperature rises. Always consult the manufacturer's "P/T rating" chart, which shows the acceptable combined limits for pressure and temperature.

Chemical Compatibility

PTFE is famously inert and resistant to nearly all industrial chemicals. This is often the primary reason it is chosen.

However, be aware of rare exceptions, such as molten alkali metals and certain halogenated compounds at high temperatures. Always cross-reference your specific medium against the manufacturer’s chemical compatibility chart.

Mechanical Stress and Creep

This is the most critical and often underestimated factor. Creep (or "cold flow") is the tendency of PTFE to deform permanently under sustained compressive stress.

Applications with frequent temperature cycles, vibration, or high bolt loads are highly susceptible to failures caused by creep. This is precisely why different grades of PTFE exist.

Virgin vs. Filled PTFE: Choosing Your Material

The distinction between virgin PTFE and filled PTFE is central to making the correct choice. Your application's mechanical demands will determine which is appropriate.

When to Use Virgin PTFE

Virgin PTFE is pure, unfilled polytetrafluoroethylene. It offers the highest chemical purity and resistance.

Choose virgin PTFE for applications where contamination is a major concern, such as in food, pharmaceutical, or high-purity electronics manufacturing. Be mindful of its lower resistance to creep, especially in high-pressure or high-temperature scenarios.

The Role of Fillers

Filled PTFE gaskets incorporate additives into the base material to enhance its physical properties. Fillers are the primary solution to PTFE's inherent mechanical weaknesses.

These fillers drastically improve the gasket's resistance to creep, increase its stiffness, and can improve thermal conductivity. The trade-off is often a slight reduction in chemical resistance compared to virgin material.

Common Fillers and Their Impact

The filler material is chosen to target a specific performance weakness. While you must consult the manufacturer's data sheet for exact specifications, common fillers include:

- Glass Fiber: A general-purpose filler that significantly improves wear and creep resistance.

- Carbon: Increases compressive strength, hardness, and wear resistance. It also adds some thermal and electrical conductivity.

- Graphite: A self-lubricating filler that reduces the coefficient of friction and improves creep resistance.

- Expanded PTFE: This is not a filler but a different material structure. It is soft and highly conformable, making it ideal for sealing irregular or damaged flange surfaces. It has excellent chemical resistance and handles a wide temperature range.

Understanding the Trade-offs and Common Pitfalls

Selecting the right material is only half the battle. Avoiding common mistakes is just as important for ensuring a reliable seal.

The Gasket Thickness Dilemma

Choosing the gasket's thickness is a crucial balancing act.

- Thicker gaskets (e.g., 1/8") can better conform to and seal warped, pitted, or uneven flange surfaces.

- Thinner gaskets (e.g., 1/16") offer higher bolt-load retention and are more resistant to creep. They require cleaner, flatter flange surfaces but provide a stronger seal in high-pressure applications.

The Importance of Flange Condition

A premium gasket cannot compensate for poorly maintained flanges. Before installation, always ensure flange surfaces are clean, dry, and free of deep scratches, burrs, or pitting.

An improperly prepared surface creates leak paths and uneven compressive load on the gasket, which can lead to premature failure regardless of the material selected.

Installation Errors Undermine Selection

A perfect gasket selection will fail if installed incorrectly. Proper installation involves:

- Careful handling and inspection of the gasket before use.

- Correct positioning and alignment on the flange.

- Tightening bolts in a star or crisscross pattern to apply even pressure.

- Using a torque wrench to achieve the specified bolt load.

Never assume a high-quality gasket can make up for a poor installation process.

Making the Right Choice for Your Goal

Your final decision should be guided by your single most important operational priority.

- If your primary focus is ultimate chemical purity: Choose virgin PTFE, but ensure your system operates well within its modest pressure and temperature limits.

- If your primary focus is sealing under high pressure or temperature cycles: Select a filled PTFE or expanded PTFE specifically engineered for high creep resistance.

- If your primary focus is sealing imperfect or delicate flanges: Use a highly conformable material like expanded PTFE, which can fill imperfections with lower bolt loads.

- If your primary focus is preventing leaks from gasket creep: Prioritize a filled PTFE gasket and ensure you use the thinnest possible option that can still achieve a seal.

A methodical approach to selection transforms a simple gasket into a predictable and reliable component of your entire system.

Summary Table:

| Selection Factor | Key Consideration | Recommended PTFE Type |

|---|---|---|

| Chemical Purity | Food, pharma, electronics | Virgin PTFE |

| High Pressure/Temperature | Resistance to creep and deformation | Filled PTFE (Glass, Carbon, Graphite) |

| Imperfect Flanges | Conformability for uneven surfaces | Expanded PTFE |

| Mechanical Stress | Frequent cycles, vibration, bolt loads | Filled PTFE |

Need a PTFE gasket engineered for your specific application? At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your gaskets are optimized for performance, durability, and reliability. Contact us today to discuss your requirements and get a solution tailored to your needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the advantages of using PTFE gaskets? Achieve Superior Chemical and Thermal Sealing

- Why are PTFE gaskets suitable for the food and beverage industry? Ensure Purity, Hygiene & Performance

- How do the non-stick properties of PTFE benefit sealing technology? Enhance Seal Life and Purity

- What are PTFE valve seat rings used for? Achieve a Leak-Proof Seal in Demanding Applications

- How does the long life and wear resistance of Teflon gland fillers reduce maintenance needs?

- What factors contribute to the durability of PTFE O-rings? Maximize Seal Life in Harsh Environments

- How does the free extrusion process enhance the yield strength of PTFE liners? Achieve Superior Axial Strength

- What are the limitations of POM as a ball valve seat material? Key Risks & Safer Alternatives