At its core, Teflon-lined carbon steel pipe is a composite material that combines the mechanical strength of a carbon steel pipe with an internal liner made of Polytetrafluoroethylene (PTFE), the material commonly known by the brand name Teflon. This design creates a robust piping system where the steel exterior provides structural integrity and pressure resistance, while the inner Teflon layer offers elite protection against chemical attack and high temperatures.

The fundamental purpose of Teflon-lined pipe is to provide a cost-effective and durable solution for transporting highly corrosive or high-purity fluids that would otherwise require expensive exotic alloy piping. It leverages the best properties of two distinct materials: the strength of steel and the resilience of Teflon.

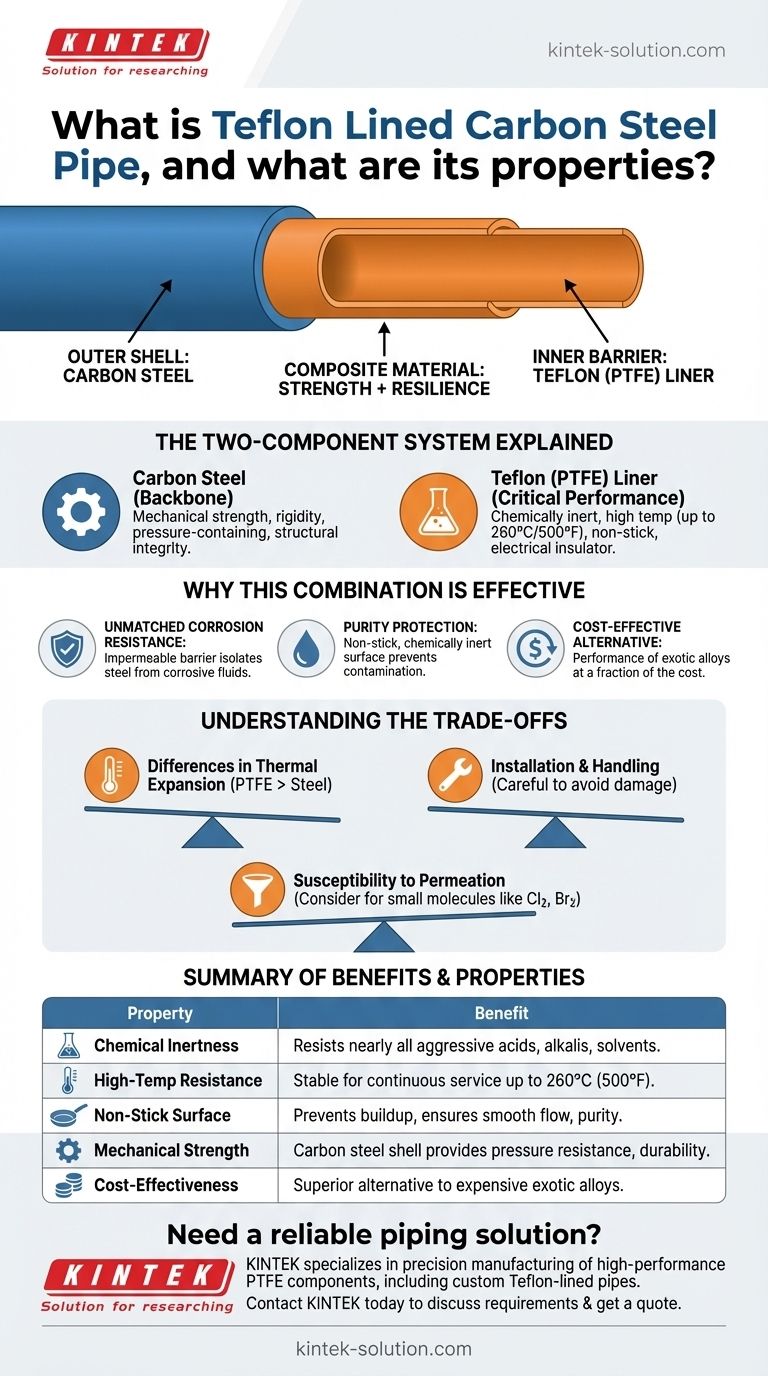

The Two-Component System Explained

To understand the value of this pipe, you must first understand its components. The final product is far more capable than the sum of its parts.

The Outer Shell: Carbon Steel

The carbon steel pipe serves as the system's backbone. It provides all the mechanical strength, rigidity, and pressure-containing capability required for industrial applications. It is a common, well-understood, and cost-effective material for structural purposes.

The Inner Barrier: The Teflon (PTFE) Liner

The liner is the critical component for performance. Teflon, or polytetrafluoroethylene (PTFE), is a synthetic fluoropolymer composed of carbon and fluorine atoms. This unique chemical structure gives it several remarkable properties.

It is chemically inert, meaning it is resistant to nearly all industrial chemicals, including aggressive acids and alkalis.

PTFE has a very broad working temperature range, remaining stable and effective at continuous service temperatures up to 230-260°C (446-500°F).

The material has an extremely low coefficient of friction, giving it powerful non-stick properties. This minimizes buildup and ensures a smooth flow for the material being transported.

Finally, it has excellent dielectric properties, making it a superb electrical insulator.

Why This Combination is So Effective

Pairing a chemically inert liner with a strong outer pipe creates a system ideal for demanding industrial environments where other materials would quickly fail.

Unmatched Corrosion Resistance

The primary benefit is preventing corrosion. The PTFE liner creates an impermeable barrier, completely isolating the carbon steel from the corrosive fluid it is transporting. This drastically extends the service life of the piping system.

Purity Protection

For industries like pharmaceuticals or food processing, product purity is paramount. The non-stick and chemically inert nature of Teflon ensures that the fluid is not contaminated by the pipe material.

A Cost-Effective Alternative to Exotic Alloys

Handling highly corrosive fluids often requires pipes made from expensive materials like Hastelloy or titanium. Teflon-lined carbon steel provides similar chemical resistance at a fraction of the cost, making it a highly economical choice.

Understanding the Trade-offs

While highly effective, this piping system is not without its specific considerations. Understanding them is key to successful implementation.

Differences in Thermal Expansion

PTFE has a much higher coefficient of thermal expansion than steel. This means it expands and contracts more with temperature changes. This must be accounted for in system design, especially in applications with frequent and significant temperature cycling.

Installation and Handling

The integrity of the liner is everything. Lined pipe requires careful handling during transport and installation to avoid scratching or damaging the PTFE surface. Specialized flange connections are used to ensure a leak-proof seal without compromising the liner.

Susceptibility to Permeation

While resistant to chemical attack, certain small-molecule gases and chemicals can slowly permeate through the PTFE liner at high temperatures. This is a specific consideration for applications involving substances like chlorine or bromine.

Making the Right Choice for Your Application

Choosing the right piping material depends entirely on the specific demands of your process.

- If your primary focus is aggressive chemical transport: The near-universal chemical inertness of the PTFE liner makes this an ideal and safe choice for handling acids, bases, and solvents.

- If your primary focus is high-temperature corrosive service: This pipe excels where plastics like PVC or CPVC would fail, maintaining its integrity well above 200°C.

- If your primary focus is maintaining product purity: The non-stick, non-leaching surface of Teflon ensures the fluid being transported remains uncontaminated.

- If your primary focus is a cost-effective, long-term solution: This system provides the performance of exotic alloys without the associated high material cost.

By understanding this composite system, you can confidently specify a material that offers both structural reliability and exceptional chemical resilience.

Summary Table:

| Property | Benefit |

|---|---|

| Chemical Inertness | Resists nearly all aggressive acids, alkalis, and solvents. |

| High-Temperature Resistance | Stable for continuous service up to 260°C (500°F). |

| Non-Stick Surface | Prevents buildup and ensures smooth flow, maintaining purity. |

| Mechanical Strength | Carbon steel shell provides pressure resistance and durability. |

| Cost-Effectiveness | Superior alternative to expensive exotic alloy piping. |

Need a reliable piping solution for corrosive or high-purity applications?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom-fabricated Teflon-lined pipes. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions from prototypes to high-volume orders.

Our expertise ensures you get a durable, cost-effective system that protects your process and your product. Contact KINTEK today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts