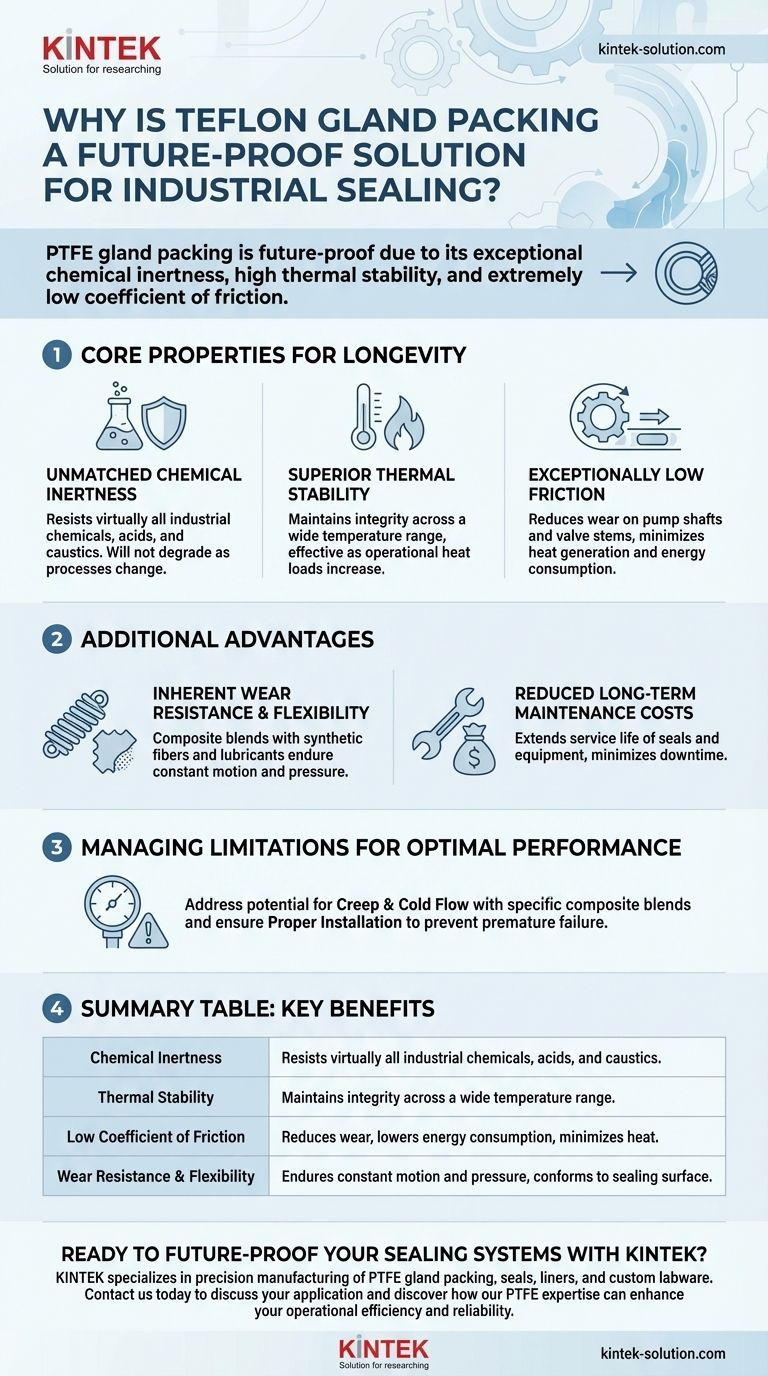

In short, Teflon (PTFE) gland packing is considered a future-proof solution due to its exceptional chemical inertness, high thermal stability, and extremely low coefficient of friction. These core material properties make it uniquely resilient to the escalating demands of modern and future industrial processes, ensuring long-term reliability where other materials may fail.

The core reason for its longevity is not just one feature, but its fundamental molecular stability. This inherent resilience allows Teflon packing to handle the increasingly aggressive chemicals, higher temperatures, and greater efficiencies that define industrial evolution.

The Foundation: What Gland Packing Must Achieve

Gland packing serves a simple but critical function: it creates a seal around a moving part, like a valve stem or a pump shaft. This seal prevents fluid from leaking out and maintains the system's internal pressure.

The Challenge of a Dynamic Seal

The effectiveness of this seal depends entirely on the packing material's ability to withstand the operational environment. This includes pressure, temperature, the chemical nature of the fluid being sealed, and the friction generated by the moving part.

Why Material Choice is Paramount

Choosing the wrong material leads to premature failure, resulting in leaks, equipment damage, safety hazards, and costly downtime. A "future-proof" material is one that can handle not only today's conditions but also the more demanding conditions of tomorrow.

Core Properties That Ensure Longevity

Teflon, or Polytetrafluoroethylene (PTFE), possesses a unique combination of characteristics that make it exceptionally durable and adaptable for sealing applications across virtually all industries.

Unmatched Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually inert to almost all industrial chemicals, acids, and caustics. This is crucial as industries develop new, more aggressive process fluids. A PTFE seal installed today will not degrade when processes change in the future.

Superior Thermal Stability

Industrial processes are constantly being optimized for efficiency, which often means running at higher temperatures. PTFE gland packing maintains its integrity and sealing capability across a very wide temperature range, ensuring it remains effective as operational heat loads increase.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This directly translates to reduced wear on expensive pump shafts and valve stems. It also means less heat is generated at the sealing point and less energy is required to operate the equipment, contributing to both mechanical longevity and energy efficiency.

Inherent Wear Resistance and Flexibility

Modern PTFE packings are not just pure Teflon. They are often complex composites woven from synthetic fibers and infused with lubricants. This construction provides excellent flexibility to conform to the sealing surface, along with high wear resistance to endure constant motion and pressure.

Understanding the Trade-offs and Limitations

No material is a perfect solution for every scenario. True technical expertise requires acknowledging the operational boundaries of even the most robust materials.

The Criticality of Proper Installation

The single most common cause of packing failure is improper installation. Over-tightening can restrict movement and cause premature wear, while under-tightening will result in leaks. The performance of PTFE packing is directly tied to following precise installation and break-in procedures.

Potential for Creep and Cold Flow

A known characteristic of PTFE is its tendency to "creep" or cold flow under sustained pressure. This means it can slowly deform over time. This is managed by using specific composite blends (e.g., carbon-filled PTFE) for high-pressure applications and by ensuring correct, consistent pressure is applied by the gland follower.

Specific Grades for Specific Needs

While "Teflon packing" is a common term, there are many different grades and composite blends. A pure PTFE packing is ideal for extreme chemical service but may not be the best choice for high-speed abrasive slurry pumps. Selecting the correct composite is essential for optimal performance.

How to Apply This to Your System

Choosing the right packing material is an investment in operational stability. Your selection should be guided by your most critical performance requirement.

- If your primary focus is aggressive chemical service: A pure or chemically inert filled PTFE packing is your most reliable choice, as it will not degrade regardless of the media.

- If your primary focus is high-speed or high-pressure pumps: A composite packing that blends PTFE with carbon or aramid fibers will provide the necessary mechanical strength and heat dissipation.

- If your primary focus is reducing long-term maintenance costs: The low-friction and non-abrasive nature of any PTFE-based packing will extend the service life of both the seal and the equipment itself.

By selecting a material engineered for fundamental resilience, you are ensuring the long-term integrity and efficiency of your critical operations.

Summary Table:

| Key Property | Benefit for Sealing Systems |

|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and caustics. |

| Thermal Stability | Maintains integrity across a wide temperature range for high-heat processes. |

| Low Coefficient of Friction | Reduces wear on equipment, lowers energy consumption, and minimizes heat generation. |

| Wear Resistance & Flexibility | Endures constant motion and pressure while conforming to the sealing surface. |

Ready to future-proof your sealing systems with high-performance PTFE components?

KINTEK specializes in the precision manufacturing of PTFE gland packing, seals, liners, and custom labware. Our solutions are engineered for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Superior Material Performance: Leverage the unmatched chemical and thermal resilience of PTFE.

- Custom Fabrication: From prototype development to high-volume production, tailored to your exact specifications.

- Long-Term Reliability: Reduce downtime and maintenance costs with components built for durability.

Contact KINTERO today to discuss your application and discover how our PTFE expertise can enhance your operational efficiency and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance