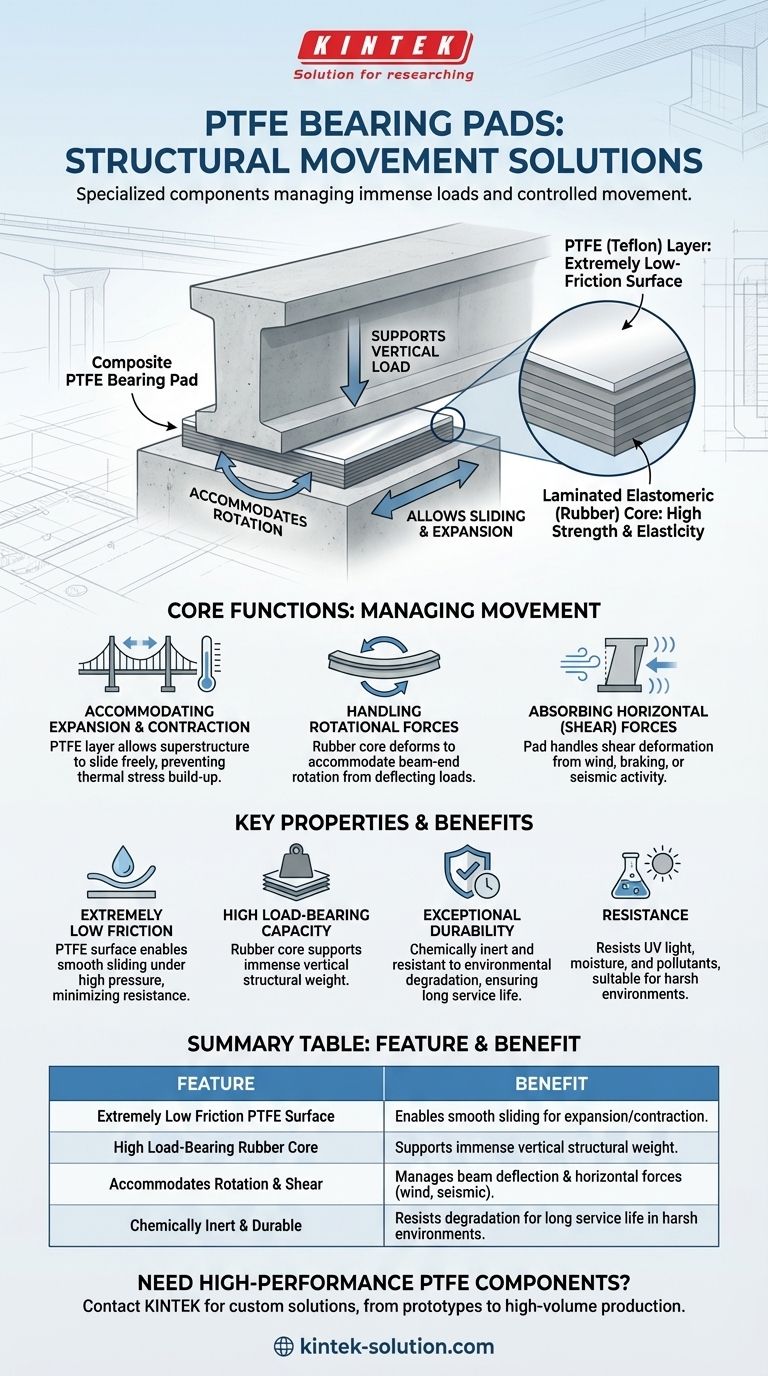

At their core, PTFE bearing pads are specialized components designed to support immense structural loads while simultaneously allowing for controlled movement. They are composite pads, typically made from laminated rubber for strength and elasticity, topped with a layer of Polytetrafluoroethylene (PTFE)—the material famously known as Teflon—which provides an extremely low-friction sliding surface.

The central purpose of a PTFE bearing pad is to solve a fundamental engineering challenge: how to let massive structures like bridges safely expand, contract, and rotate without building up destructive internal stress. They achieve this by combining high vertical load capacity with a durable, nearly frictionless surface for horizontal movement.

The Core Function: Managing Structural Movement

Large structures are not static; they move in response to temperature changes, traffic loads, and environmental forces. PTFE bearing pads are engineered to manage these movements in three distinct ways.

Accommodating Expansion and Contraction

All materials expand when heated and contract when cooled. For a long bridge span, this thermal movement can be significant. The PTFE layer provides a sliding plane that allows the superstructure to move freely, preventing immense stress from building up in the support columns and abutments.

Handling Rotational Forces

As a beam deflects under a load (like a truck driving over a bridge), its ends rotate slightly. The high elasticity of the underlying rubber pad allows it to deform and accommodate this beam-end rotation, ensuring the load is transferred evenly to the support structure.

Absorbing Horizontal (Shear) Forces

Forces like wind, braking, or seismic activity push on a structure horizontally. The bearing pad is designed to handle this shear deformation, absorbing a portion of the horizontal force and allowing for controlled displacement.

Key Properties of PTFE Pads

The effectiveness of these pads comes from the unique combination of the robust rubber core and the high-performance PTFE surface.

Extremely Low Friction Coefficient

PTFE has one of the lowest coefficients of friction of any solid material, even under the high pressure of a bridge deck. This allows the structural elements to slide smoothly over one another with minimal resistance.

High Load-Bearing Capacity

While the PTFE provides the slide, the laminated elastomeric (rubber) bearing pad underneath supports the immense vertical weight of the structure. This composite design is what allows the pad to handle both load and movement.

Exceptional Durability and Resistance

PTFE is chemically inert and highly resistant to environmental degradation from UV light, moisture, and pollutants. This ensures a long and reliable service life, which is critical for infrastructure components that are difficult to inspect or replace.

Understanding the Trade-offs

While highly effective, the performance of PTFE pads is contingent on proper design and application. Understanding their limitations is key to their successful implementation.

Dependence on the Composite Structure

A sheet of pure PTFE would be useless for this application. Its strength comes from being bonded to the laminated rubber bearing. The integrity of this bond is critical; any delamination between the PTFE and the rubber would constitute a failure.

Sensitivity to Conditions

The friction coefficient of PTFE, while always low, can be influenced by factors like temperature, contact pressure, and sliding speed. Engineers must account for these variables when designing the bearing for a specific application.

Proper Installation is Non-Negotiable

The effectiveness of a bearing pad is entirely dependent on its correct installation. An uneven or improperly prepared surface can create pressure points, restrict movement, and ultimately compromise the function of the pad and the safety of the structure.

Making the Right Choice for Your Goal

The decision to use a PTFE bearing pad is driven by the specific movements a structure must accommodate.

- If your primary focus is accommodating large horizontal movement: PTFE sliding pads are the industry standard for bridges with long spans where thermal expansion and contraction are significant.

- If your primary focus is supporting massive vertical loads with some rotation: A standard laminated elastomeric bearing may suffice, but adding the PTFE layer becomes essential if horizontal sliding is also expected.

- If your primary focus is long-term resilience in harsh environments: The chemical and environmental resistance of PTFE makes these pads a highly reliable choice for critical, long-life infrastructure.

Ultimately, PTFE bearing pads are a critical engineering solution that enables modern, large-scale structures to safely breathe and move as intended.

Summary Table:

| Feature | Benefit |

|---|---|

| Extremely Low Friction PTFE Surface | Enables smooth sliding for expansion/contraction |

| High Load-Bearing Rubber Core | Supports immense vertical structural weight |

| Accommodates Rotation & Shear | Manages beam deflection and horizontal forces (e.g., wind, seismic) |

| Chemically Inert & Durable | Resists degradation for long service life in harsh environments |

Need high-performance PTFE components for your critical applications?

KINTEK specializes in the precision manufacturing of PTFE seals, liners, labware, and custom components. Our expertise is crucial for industries where material performance and reliability are non-negotiable, including semiconductor, medical, laboratory, and industrial sectors.

We understand the engineering challenges you face. Let us provide the custom PTFE solutions you need, from prototypes to high-volume production, ensuring your projects meet the highest standards of durability and precision.

Contact KINTEK today to discuss your specific requirements and how our PTFE expertise can benefit your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications