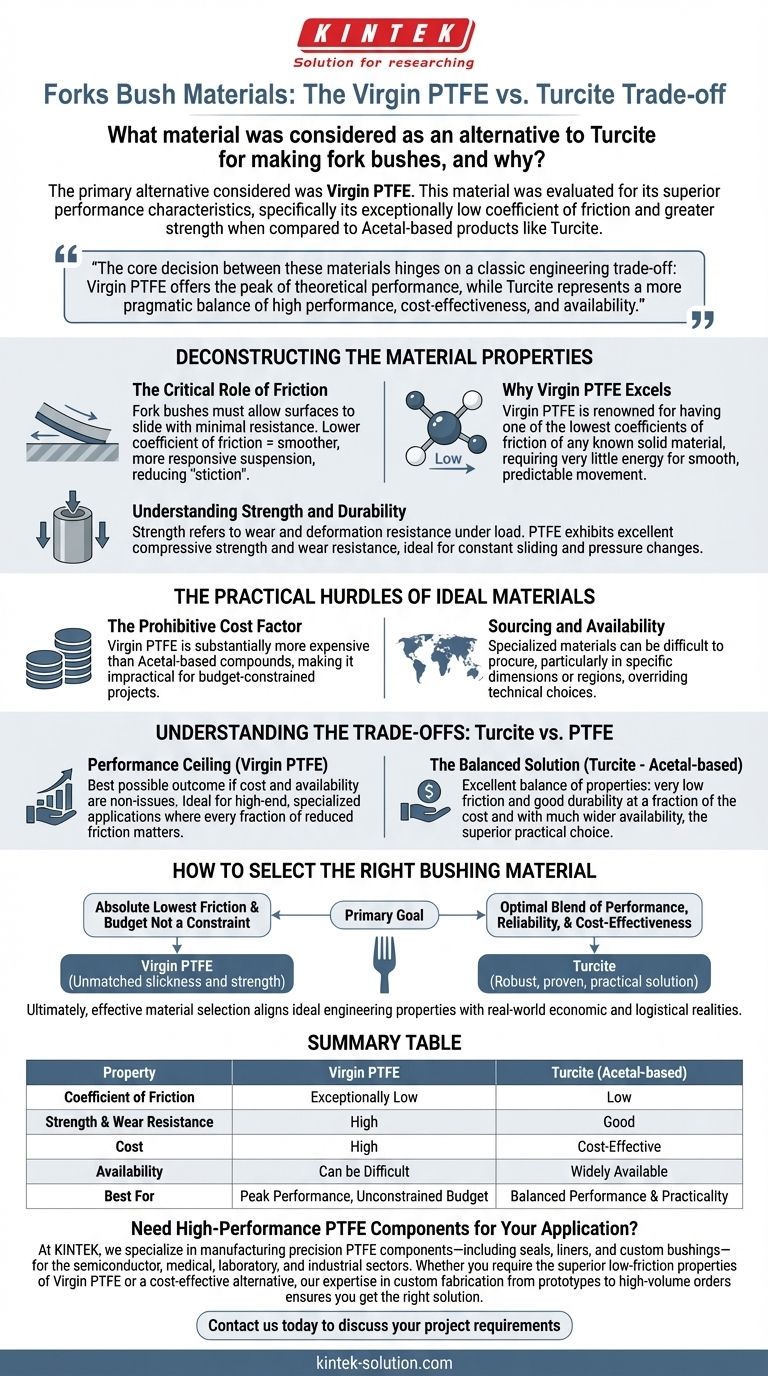

The primary alternative considered was Virgin PTFE. This material was evaluated for its superior performance characteristics, specifically its exceptionally low coefficient of friction and greater strength when compared to Acetal-based products like Turcite.

The core decision between these materials hinges on a classic engineering trade-off: Virgin PTFE offers the peak of theoretical performance, while Turcite represents a more pragmatic balance of high performance, cost-effectiveness, and availability.

Deconstructing the Material Properties

When selecting a material for a dynamic application like fork bushes, the specific mechanical properties are the most critical factors. The goal is to minimize resistance to movement while ensuring long-term durability.

The Critical Role of Friction

Fork bushes must allow two surfaces to slide against each other with minimal resistance. A lower coefficient of friction directly translates to smoother, more responsive suspension action by reducing "stiction"—the initial force required to start movement.

Why Virgin PTFE Excels

Virgin PTFE (Polytetrafluoroethylene) is renowned for having one of the lowest coefficients of friction of any known solid material. This inherent slipperiness means it requires very little energy to overcome static friction, providing exceptionally smooth and predictable movement right from the start.

Understanding Strength and Durability

The term "stronger" in this context refers to the material's ability to resist wear and deformation under load. PTFE exhibits excellent compressive strength and wear resistance, making it highly suitable for bushings that must endure the constant sliding and pressure changes within a suspension fork.

The Practical Hurdles of Ideal Materials

While Virgin PTFE has superior technical specifications on paper, real-world engineering decisions are always governed by practical constraints.

The Prohibitive Cost Factor

High-performance materials often come with a significant price premium. Virgin PTFE is substantially more expensive than Acetal-based compounds, which can make it an impractical choice for many projects or products where budget is a key consideration.

Sourcing and Availability

Specialized materials can also be difficult to procure, particularly in specific dimensions or regions. The noted difficulty in sourcing PTFE in Australia highlights how supply chain logistics can override an otherwise ideal technical choice.

Understanding the Trade-offs: Turcite vs. PTFE

Choosing between these materials is not about which is "better" in absolute terms, but which is more appropriate for the specific application's goals and constraints.

Performance Ceiling vs. Practical Application

Virgin PTFE represents the performance ceiling—the best possible outcome if cost and availability are non-issues. Its properties are ideal for high-end, specialized applications where every fraction of reduced friction matters.

The Balanced Solution

Turcite, an Acetal-based composite, is engineered to provide an excellent balance of properties. It offers very low friction and good durability at a fraction of the cost and with much wider availability, making it the superior practical choice for the vast majority of applications.

How to Select the Right Bushing Material

Your final decision should be guided by the primary goal of your project.

- If your primary focus is achieving the absolute lowest friction possible and budget is not a constraint: Virgin PTFE is the technically superior material for its unmatched slickness and strength.

- If your primary focus is an optimal blend of high performance, reliability, and cost-effectiveness: Turcite or similar Acetal-based products provide a robust and proven solution that meets the needs of most applications.

Ultimately, effective material selection is about aligning the ideal engineering properties with real-world economic and logistical realities.

Summary Table:

| Property | Virgin PTFE | Turcite (Acetal-based) |

|---|---|---|

| Coefficient of Friction | Exceptionally Low | Low |

| Strength & Wear Resistance | High | Good |

| Cost | High | Cost-Effective |

| Availability | Can be Difficult | Widely Available |

| Best For | Peak Performance, Unconstrained Budget | Balanced Performance & Practicality |

Need High-Performance PTFE Components for Your Application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom bushings—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the superior low-friction properties of Virgin PTFE or a cost-effective alternative, our expertise in custom fabrication from prototypes to high-volume orders ensures you get the right solution.

Contact us today to discuss your project requirements and let our team deliver the durability and performance your application demands.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments