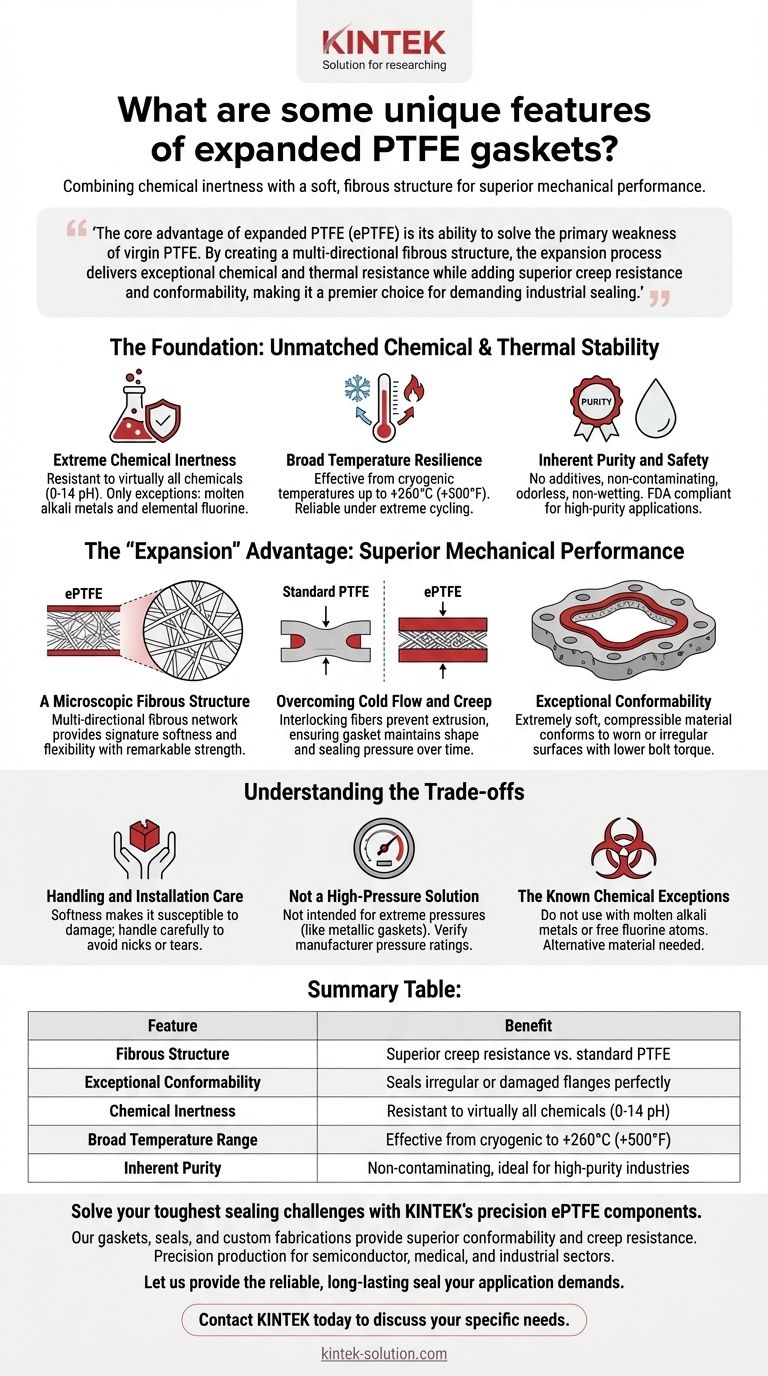

The truly unique feature of expanded PTFE is not just its chemical inertness, but how it combines that quality with a soft, fibrous structure that provides superior mechanical performance. This expansion process transforms standard PTFE, creating a gasket material that dramatically resists the "cold flow" or "creep" that plagues other fluoropolymers, allowing it to maintain a reliable seal under pressure on even irregular surfaces.

The core advantage of expanded PTFE (ePTFE) is its ability to solve the primary weakness of virgin PTFE. By creating a multi-directional fibrous structure, the expansion process delivers exceptional chemical and thermal resistance while adding superior creep resistance and conformability, making it a premier choice for demanding industrial sealing.

The Foundation: Unmatched Chemical & Thermal Stability

Expanded PTFE inherits its core strengths from its parent material, polytetrafluoroethylene. This provides a baseline of performance that few other materials can match.

Extreme Chemical Inertness

Composed entirely of carbon and fluorine, ePTFE is resistant to virtually all chemicals across the entire 0-14 pH range.

Its only known exceptions are highly reactive substances like molten alkali metals and elemental fluorine, making it suitable for the most aggressive industrial services.

Broad Temperature Resilience

The material functions effectively across an exceptionally wide thermal range, from cryogenic temperatures up to +260°C (500°F).

This stability ensures a reliable seal in applications involving extreme temperature cycling without becoming brittle or degrading.

Inherent Purity and Safety

Because the expansion process requires no additives, ePTFE maintains the purity of virgin PTFE. It is non-contaminating, odorless, and non-wetting.

This makes it compliant with FDA regulations and ideal for use in food processing, pharmaceutical, and other high-purity applications.

The "Expansion" Advantage: Superior Mechanical Performance

The special manufacturing process that creates ePTFE is what unlocks its most unique and valuable features. It turns a solid polymer into a highly structured, porous, and flexible material.

A Microscopic Fibrous Structure

Unlike solid PTFE, ePTFE has a multi-directional network of internal fibers. This structure is key to its enhanced mechanical properties.

This fibrous matrix gives the material its signature softness and flexibility while providing remarkable strength.

Overcoming Cold Flow and Creep

The most significant advantage of ePTFE is its superior resistance to creep and cold flow.

Standard PTFE gaskets can slowly extrude or "flow" out from between flanges under compressive load, eventually causing the seal to fail. The interlocking fibers in ePTFE prevent this, ensuring the gasket maintains its shape and sealing pressure over time.

Exceptional Conformability

Expanded PTFE is extremely soft and compressible. This allows it to conform perfectly to worn, pitted, or irregular flange surfaces.

This feature ensures a tight, reliable seal with lower bolt torque, which is especially critical for protecting fragile or non-metallic flanges like glass-lined steel or plastic.

Understanding the Trade-offs

While ePTFE is a superior sealing material in many contexts, it's important to recognize its operational boundaries to ensure proper application.

Handling and Installation Care

The softness that makes ePTFE so conformable also makes it more susceptible to damage before or during installation. It must be handled carefully to avoid nicks or tears that could compromise the seal.

Not a High-Pressure Solution

While it has excellent creep resistance for a soft gasket, ePTFE is not intended for the extreme pressures handled by metallic or semi-metallic gaskets like spiral wound types. Always verify the manufacturer's pressure ratings for the specific product.

The Known Chemical Exceptions

It is critical to remember the material's limitations. In the rare applications involving molten alkali metals or free fluorine atoms, an alternative material must be selected.

Making the Right Choice for Your Application

Selecting ePTFE is a strategic decision based on overcoming specific sealing challenges that other materials cannot address.

- If your primary focus is sealing aggressive chemicals: ePTFE’s near-universal chemical inertness provides unmatched reliability and safety.

- If you are dealing with irregular or damaged flanges: Its exceptional softness and conformability create a reliable, leak-free seal where harder gaskets would fail.

- If you need to prevent seal extrusion (cold flow): The unique fibrous structure provides superior creep resistance compared to standard PTFE, ensuring a long-term, stable seal.

- If you are working with delicate equipment (e.g., glass-lined steel): Its high compressibility allows for a tight seal with lower bolt loads, preventing costly damage to the flange.

By leveraging the unique mechanical advantages born from its expanded structure, you can confidently specify ePTFE for your most demanding sealing challenges.

Summary Table:

| Feature | Benefit |

|---|---|

| Fibrous Structure | Superior creep resistance vs. standard PTFE |

| Exceptional Conformability | Seals irregular or damaged flanges perfectly |

| Chemical Inertness | Resistant to virtually all chemicals (0-14 pH) |

| Broad Temperature Range | Effective from cryogenic to +260°C (+500°F) |

| Inherent Purity | Non-contaminating, ideal for high-purity industries |

Solve your toughest sealing challenges with KINTEK's precision ePTFE components.

Our expanded PTFE gaskets, seals, and custom fabrications are engineered to provide the superior conformability and creep resistance detailed in this article. Whether you're in the semiconductor, medical, laboratory, or industrial sector, KINTEK prioritizes precision production from prototypes to high-volume orders.

Let us provide the reliable, long-lasting seal your application demands.

Contact KINTEK today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers