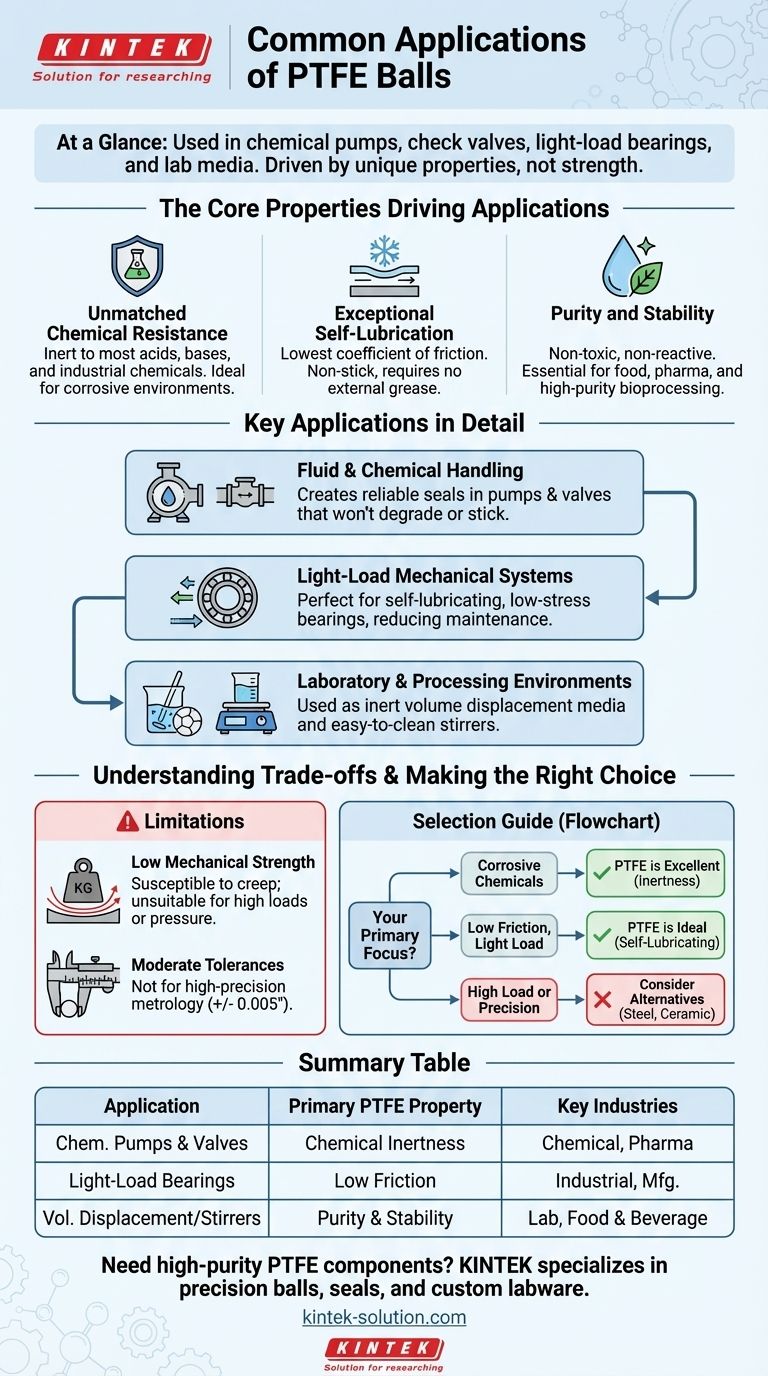

At a glance, PTFE balls are most commonly used in chemical handling pumps, check valves, light-load ball bearings, and as volume displacement media in chemical baths. Their prevalence across the chemical, pharmaceutical, and food manufacturing industries is driven by a unique set of material properties rather than mechanical strength.

The core reason for PTFE's widespread use is its near-total chemical inertness and exceptionally low friction. These two characteristics make it the default choice for applications involving corrosive fluids or where self-lubrication is a critical design requirement.

The Core Properties Driving PTFE Ball Applications

To understand where to use PTFE balls, it's essential to first understand the material itself. Its applications are a direct result of its distinct advantages and limitations.

Unmatched Chemical Resistance

PTFE is virtually inert, meaning it does not react with the vast majority of industrial chemicals, acids, and bases. This makes it an ideal material for components that are in constant contact with corrosive or high-purity fluids.

This property is critical in chemical processing equipment, transport systems, and pharmaceutical manufacturing, where material reactivity could contaminate the product or lead to equipment failure.

Exceptional Self-Lubrication

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. It is inherently non-stick and self-lubricating, requiring no external oils or greases.

This makes it perfect for components in motion, such as check valves and light-load bearings, where smooth, repeatable operation is necessary without the risk of contamination from lubricants.

Purity and Stability

In industries like food manufacturing and bioprocessing, maintaining the purity of the product is paramount. PTFE is non-toxic and does not impart taste, odor, or contaminants into the substances it touches.

Its use in laboratory stirrers and as seals or gaskets in sanitary systems stems from this need for a clean, stable, and non-reactive contact surface.

Key Applications in Detail

These core properties translate directly into specific industrial and scientific uses.

Fluid and Chemical Handling

The most common application is in equipment that moves or controls corrosive fluids. In chemical handling pumps and check valves, PTFE balls create a reliable seal that won't degrade from chemical exposure or stick to the valve seat.

Light-Load Mechanical Systems

Because PTFE is a relatively soft material, it is reserved for light-load ball bearings. In these scenarios, its self-lubricating nature is the primary benefit, reducing complexity and maintenance in low-stress mechanical assemblies.

Laboratory and Processing Environments

In chemical labs and industrial baths, PTFE balls serve as volume displacement media. They are added to tanks to raise the fluid level without reacting with the chemical solution, conserving expensive or hazardous materials. Their use as stirrers is also common due to their inertness and easy-to-clean surface.

Understanding the Trade-offs and Limitations

While highly effective in its niche, PTFE is not a universal solution. Acknowledging its limitations is key to successful application.

Low Mechanical Strength

PTFE is not a strong material. It is susceptible to "creep," meaning it can slowly deform over time under a constant load. It is unsuitable for high-pressure systems or high-load bearings where structural integrity is critical.

Moderate Dimensional Tolerances

As a softer plastic, PTFE balls cannot be manufactured to the same tight precision as steel or ceramic balls. Typical tolerances are around +/- 0.005 inches, making them unsuitable for high-precision metrology or positioning applications.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary goal.

- If your primary focus is handling corrosive chemicals: PTFE is an excellent first choice for any component in the fluid path due to its extreme inertness.

- If your primary focus is a low-friction, self-lubricating mechanism: PTFE is ideal for light-load bearings or non-stick valve components where external lubricants are undesirable.

- If your primary focus is high-load capacity or dimensional precision: You must consider alternative materials like stainless steel, ceramic, or harder engineering plastics.

Leveraging PTFE balls effectively means embracing their unparalleled chemical and friction properties while respecting their mechanical limitations.

Summary Table:

| Application | Primary PTFE Property Utilized | Key Industries |

|---|---|---|

| Chemical Pumps & Valves | Chemical Inertness | Chemical, Pharmaceutical |

| Light-Load Bearings | Low Friction / Self-Lubrication | Industrial, Manufacturing |

| Volume Displacement Media / Stirrers | Purity & Chemical Stability | Laboratory, Food & Beverage |

Need high-purity, chemically inert PTFE components for your application?

KINTEK specializes in manufacturing precision PTFE balls, seals, liners, and custom labware. Whether you require standard parts or custom-fabricated prototypes for the semiconductor, medical, laboratory, or industrial sectors, we deliver components that meet stringent purity and performance standards.

Contact our experts today to discuss how our PTFE solutions can enhance the reliability and longevity of your equipment.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why are PTFE gaskets used in the petrochemical industry? For Superior Chemical & Thermal Resistance

- What are the operational benefits of PTFE Lip Seals? Unlock Reliability in Extreme Conditions

- What industries commonly use Teflon CNC machined parts? Critical Solutions for Aerospace, Medical & More

- What additional advantages does expanded PTFE offer? Superior Sealing, Stability & Purity for Critical Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How do PTFE oil seals and conventional oil seals differ in terms of lubrication requirements? Unlock Superior Performance

- In which industries are PTFE ball valves commonly used? Essential for Chemical Resistance & Purity

- What industries are PTFE gasket envelopes suitable for? Find the Perfect Seal for Demanding Applications