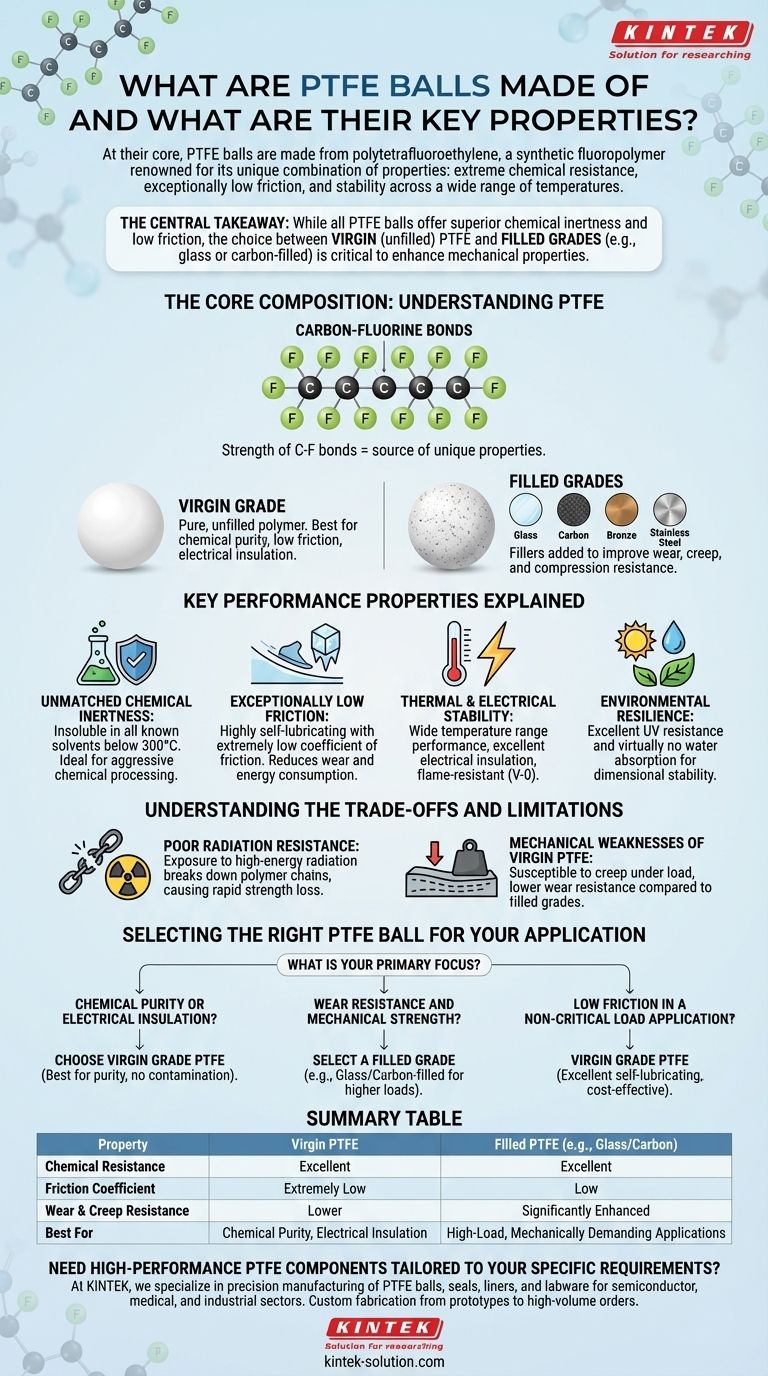

At their core, PTFE balls are made from polytetrafluoroethylene, a synthetic fluoropolymer renowned for its unique combination of properties. They are prized in engineering and manufacturing for their extreme chemical resistance, exceptionally low friction, and stability across a wide range of temperatures.

The central takeaway is that while all PTFE balls offer superior chemical inertness and low friction, the choice between virgin (unfilled) PTFE and filled grades (e.g., glass or carbon-filled) is critical, as fillers are used to enhance mechanical properties like wear resistance and strength for more demanding applications.

The Core Composition: Understanding PTFE

PTFE balls are not a single, uniform product. The specific grade of material used dictates its performance characteristics and suitability for a given task.

What is Polytetrafluoroethylene (PTFE)?

PTFE is a fluoropolymer created from the polymerization of tetrafluoroethylene. Its molecular structure consists of a carbon chain completely surrounded by fluorine atoms.

The strength of these carbon-fluorine bonds is the source of PTFE's most valuable properties, giving it a unique profile that is difficult to replicate with other polymers.

Virgin Grade vs. Filled Grades

Virgin PTFE is the pure, unfilled polymer. It is used when chemical purity, low friction, and electrical insulation are the primary requirements.

To improve mechanical performance, various materials are added to create filled grades. Common fillers include glass, carbon, bronze, or even stainless steel, which significantly enhance the ball's resistance to wear, creep, and compression.

Key Performance Properties Explained

The value of PTFE balls comes from a distinct set of characteristics that make them ideal for challenging environments where other materials would fail.

Unmatched Chemical Inertness

PTFE is insoluble in all known solvents below 300°C (572°F). This makes it the material of choice for components used in aggressive chemical processing, such as in valves, pumps, and bearings.

Exceptionally Low Friction

With one of the lowest coefficients of friction of any solid material, PTFE is highly self-lubricating. This "non-stick" property reduces wear and energy consumption in moving parts, allowing systems to operate smoothly without external lubricants.

Thermal and Electrical Stability

PTFE balls maintain their properties over a wide temperature range and possess excellent electrical insulating capabilities. They are also highly flame-resistant, with a flammability rating of V-0.

Environmental Resilience

The material has excellent resistance to ultraviolet (UV) light and absorbs virtually no water (0.01% over 24 hours). This ensures dimensional stability and long-term performance in outdoor or humid applications.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging the inherent limitations of PTFE is crucial for correct application and avoiding premature failure.

Poor Radiation Resistance

The primary weakness of PTFE is its poor resistance to high-energy radiation. Exposure to gamma rays or electron beams can cause the polymer chains to break down, leading to a rapid loss of mechanical strength.

Mechanical Weaknesses of Virgin PTFE

While chemically stable, virgin PTFE is a relatively soft material. It can be susceptible to creep (deformation under sustained load) and has lower wear resistance compared to harder plastics or metals. This is precisely why filled grades were developed for mechanically demanding roles.

Selecting the Right PTFE Ball for Your Application

Your choice should be dictated entirely by the demands of the specific environment and application.

- If your primary focus is chemical purity or electrical insulation: Choose virgin grade PTFE, as it offers the best performance in these areas without potential contamination from fillers.

- If your primary focus is wear resistance and mechanical strength: Select a filled grade, such as glass-filled or carbon-filled PTFE, to handle higher loads and abrasive conditions.

- If your primary focus is low-friction in a non-critical load application: Virgin grade PTFE provides excellent self-lubricating properties and is often the most cost-effective choice.

Ultimately, understanding the interplay between PTFE's inherent strengths and its engineered variations is the key to leveraging this remarkable material effectively.

Summary Table:

| Property | Virgin PTFE | Filled PTFE (e.g., Glass/Carbon) |

|---|---|---|

| Chemical Resistance | Excellent | Excellent |

| Friction Coefficient | Extremely Low | Low |

| Wear & Creep Resistance | Lower | Significantly Enhanced |

| Best For | Chemical Purity, Electrical Insulation | High-Load, Mechanically Demanding Applications |

Need high-performance PTFE components tailored to your specific requirements?

At KINTEK, we specialize in the precision manufacturing of PTFE balls, seals, liners, and labware. Whether your application demands the ultimate chemical purity of virgin PTFE or the enhanced mechanical strength of filled grades for the semiconductor, medical, or industrial sectors, we provide custom fabrication from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE solutions can solve your unique engineering challenges.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the overall advantages of using PTFE balls in fluid management systems? Enhance Reliability & Efficiency

- In which industries are Teflon (PTFE) balls commonly used? Key Applications & Benefits

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments

- What factors determine the different grades of PTFE balls available? Select the Right Grade for Your Application

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime