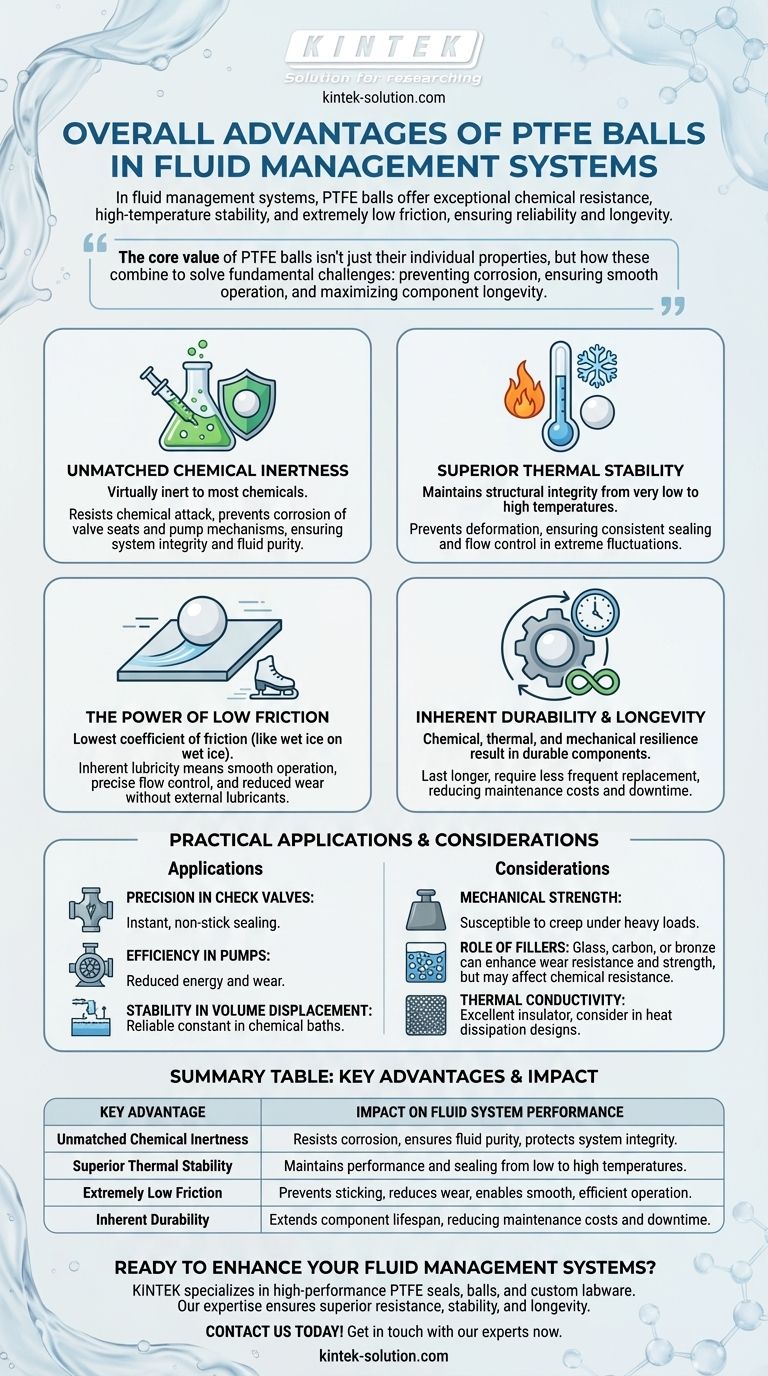

In fluid management systems, the primary advantages of using PTFE balls stem from their exceptional chemical resistance, high-temperature stability, and extremely low coefficient of friction. These inherent material properties translate directly into greater system reliability, reduced maintenance, and precise operational control, especially in chemically aggressive or high-heat environments where conventional materials would quickly fail.

The core value of PTFE balls isn't just their individual properties, but how these properties combine to solve the fundamental challenges of fluid management: preventing corrosion, ensuring smooth operation, and maximizing the longevity of critical components.

Why PTFE Excels in Demanding Fluid Systems

The effectiveness of Polytetrafluoroethylene (PTFE) comes from a unique molecular structure that gives it a powerful combination of characteristics. Understanding how each property impacts system performance is key to leveraging its full potential.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and solvents. This quality is critical in applications involving corrosive or high-purity fluids.

By resisting chemical attack, PTFE balls prevent corrosion of vital components like valve seats and pump mechanisms. This ensures the integrity of the system and the purity of the fluid being managed.

Superior Thermal Stability

Fluid systems often operate under a wide range of temperatures. PTFE balls maintain their structural integrity and performance characteristics from very low temperatures up to high heat conditions.

This thermal resilience prevents deformation or degradation, ensuring consistent sealing and flow control even during extreme temperature fluctuations.

The Power of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This inherent lubricity means parts move smoothly without the need for external lubricants.

In components like check valves, this non-stick property guarantees that the ball seats and unseats perfectly without sticking, preventing blockages and ensuring precise, responsive flow control. This also significantly reduces wear on adjacent parts.

Inherent Durability and Longevity

The combination of chemical, thermal, and mechanical resilience makes PTFE a highly durable material.

Components made from PTFE last longer and require less frequent replacement. This translates directly to reduced maintenance costs, less system downtime, and greater overall operational reliability.

Practical Applications in Fluid Control

The theoretical benefits of PTFE are proven in its widespread use across various industries. Its properties make it the ideal choice for specific, challenging roles within fluid management.

Precision in Check Valves

In a check valve, a PTFE ball provides a perfect, non-stick seal that responds instantly to changes in pressure. Its chemical inertness means it won't swell, soften, or degrade, regardless of the fluid passing through.

Efficiency in Pumps and Bearings

For chemical handling pumps and light-load bearings, the low-friction nature of PTFE is paramount. It reduces the energy required for operation and minimizes wear, contributing to a longer, more efficient service life.

Stability in Volume Displacement

PTFE balls are often used in chemical baths for volume displacement. Their chemical and thermal stability ensures they do not react with the bath's contents or degrade over time, providing a reliable constant.

Understanding the Trade-offs and Considerations

While PTFE is an exceptional material, no single solution is perfect for every scenario. Acknowledging its limitations is crucial for proper application design.

Mechanical Strength

Compared to metals, standard PTFE has lower mechanical strength and can be susceptible to creep under heavy, sustained loads. It is best suited for light-to-moderate load-bearing applications.

The Role of Fillers

To overcome some mechanical limitations, manufacturers offer various grades of PTFE that include fillers like glass, carbon, or bronze. These additives can significantly enhance properties like wear resistance, thermal conductivity, and compressive strength.

Choosing the right grade is essential. A filled PTFE may offer better mechanical performance but could have slightly reduced chemical resistance depending on the filler material.

Thermal Conductivity

PTFE is an excellent thermal insulator. While often an advantage, this low thermal conductivity must be considered in applications where heat dissipation is a critical design requirement.

Making the Right Choice for Your System

Selecting the right material is a function of your primary operational goal. PTFE offers a distinct set of advantages for specific challenges.

- If your primary focus is handling corrosive chemicals: PTFE's inertness is its greatest asset, protecting your system from degradation and ensuring fluid purity.

- If your primary focus is high-temperature environments: Its thermal stability ensures consistent, reliable performance where other polymers would deform or fail.

- If your primary focus is operational efficiency and low maintenance: Its extremely low friction and durable nature minimize wear and prevent sticking, drastically reducing system downtime.

Ultimately, choosing PTFE balls is a strategic decision to enhance the reliability and longevity of your most critical fluid management systems.

Summary Table:

| Key Advantage | Impact on Fluid System Performance |

|---|---|

| Unmatched Chemical Inertness | Resists corrosion, ensures fluid purity, and protects system integrity. |

| Superior Thermal Stability | Maintains performance and sealing from low to high temperatures. |

| Extremely Low Friction | Prevents sticking, reduces wear, and enables smooth, efficient operation. |

| Inherent Durability | Extends component lifespan, reducing maintenance costs and downtime. |

Ready to enhance the reliability and efficiency of your fluid management systems with precision PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, balls, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get components that deliver superior chemical resistance, thermal stability, and longevity.

Contact us today to discuss your specific requirements and discover how our PTFE solutions can solve your toughest fluid management challenges.

Get in touch with our experts now!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What are the common applications of virgin Teflon balls? Ideal for Chemical Resistance & Purity

- What is the first step in both PTFE production methods? Unlocking the Key to High-Performance Polymer Manufacturing

- What makes Teflon gland fillers effective for sealing applications in the chemical industry? Superior Chemical Resistance and Reliability

- What role do fillers play in structured PTFE? Enhancing Strength, Wear, and Thermal Performance

- What is the main difference between PTFE and expanded PTFE? Unlock the Right Material for Your Application

- What are the available sizes and thicknesses for PTFE sheets? A Guide for Engineers & Designers

- What are the disadvantages of solid Teflon O-rings? Key Limitations for Reliable Sealing

- How do spring energized PTFE seals compare to elastomeric seals in dynamic service? Superior Performance in Extreme Conditions