The primary disadvantage of solid Teflon O-rings is their profound lack of elasticity. Unlike traditional rubber O-rings that compress and rebound to create a tight seal, solid Teflon (PTFE) is a rigid plastic. This fundamental difference leads to significant challenges in installation, compression sealing, and long-term reliability in applications that experience pressure or temperature fluctuations.

While valued for their unparalleled chemical and thermal resistance, solid Teflon O-rings function more like a precision gasket than a flexible seal. Their rigidity is their greatest weakness, demanding very specific engineering conditions to prevent leaks.

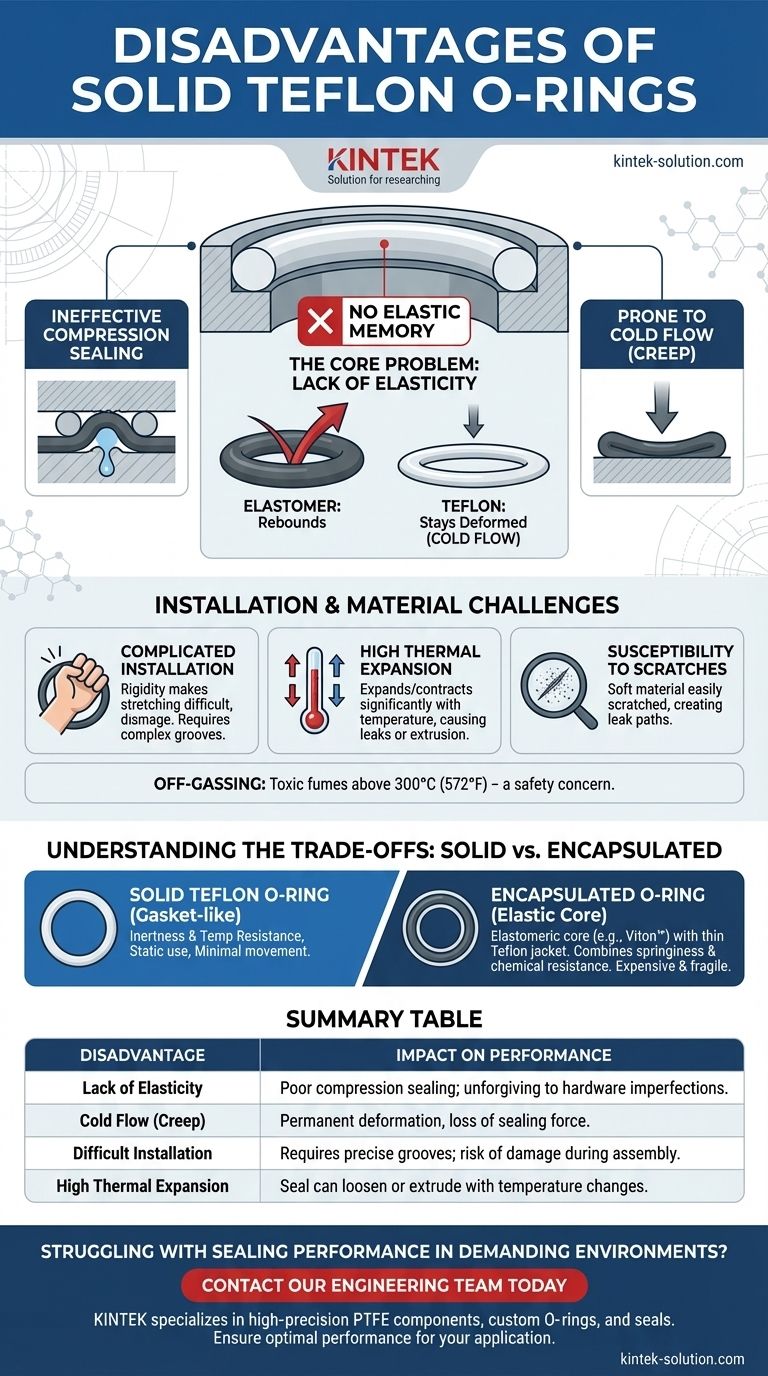

The Core Problem: Lack of Elastic Memory

The defining characteristic of an elastomer (rubber) is its ability to return to its original shape after being compressed. Solid Teflon lacks this "memory," which is the root cause of its primary disadvantages.

Ineffective Compression Sealing

A standard O-ring works by being squeezed into a groove, where it pushes back against the mating surfaces. Because solid Teflon doesn't push back with any meaningful force, it creates a much less forgiving seal. Any imperfection in the hardware or change in conditions can create a leak path.

Prone to Cold Flow (Creep)

Under sustained pressure, even at room temperature, Teflon will slowly and permanently deform. This phenomenon, known as cold flow or creep, causes the O-ring to flatten over time, progressively losing whatever initial sealing force was applied.

Complicated and Risky Installation

The rigidity of solid Teflon makes it difficult to install. It cannot be stretched over components like a rubber O-ring can. This often necessitates complex groove designs (like split grooves) or risks scratching or damaging the O-ring and the hardware during assembly, which will compromise the seal.

Material and Thermal Limitations

Beyond its lack of flexibility, Teflon's inherent material properties introduce further challenges for sealing applications.

High Thermal Expansion

Teflon has a very high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. This rate is much higher than that of the metals it is typically sealing against, such as steel or aluminum. A seal that is tight at room temperature may loosen and leak at low temperatures or extrude from its groove at high temperatures.

Susceptibility to Scratches

While Teflon is known for its low-friction surface, the material itself is relatively soft. It can be easily scratched or damaged by abrasive particles within a system, creating a direct leak path across the sealing face.

Off-Gassing at Extreme Temperatures

Though Teflon's maximum continuous operating temperature is around 260°C (500°F), it will begin to decompose and release toxic fumes if heated above 300°C (572°F). This is primarily a safety concern in case of system overheating, not a limitation within its normal operating range.

Understanding the Trade-offs: Solid vs. Encapsulated O-Rings

To overcome the drawbacks of solid Teflon, engineers often consider an alternative: the Teflon encapsulated O-ring. Understanding the difference is critical.

The Profile of a Solid Teflon Ring

A solid Teflon O-ring is a single piece of machined or molded PTFE. It is chosen when chemical inertness and temperature resistance are the absolute priorities and the application is typically static (no movement) with minimal pressure or temperature cycling.

The Advantage of an Encapsulated Ring

An encapsulated O-ring features an elastomeric core (like Viton™ or Silicone) covered by a thin, seamless jacket of Teflon. This design combines the springiness of a rubber O-ring with the chemical resistance of a Teflon surface.

The Downsides of Encapsulation

This solution introduces its own compromises. The thin Teflon jacket is fragile and can be easily damaged by scratches or abrasion, exposing the vulnerable core. Furthermore, these composite O-rings are significantly more expensive due to their complex manufacturing process.

Making the Right Choice for Your Application

Choosing the correct material requires a clear understanding of your operational demands and accepting the inherent trade-offs of each option.

- If your primary focus is sealing aggressive chemicals in a static face seal: A solid Teflon O-ring may be suitable, provided the groove design is precise and temperature fluctuations are minimal.

- If your application involves dynamic movement or requires frequent assembly: The rigidity and poor elastic recovery of solid Teflon make it a high-risk choice that will likely fail.

- If you need both chemical resistance and reliable, long-term compression sealing: A Teflon encapsulated O-ring is often a better, albeit more expensive and fragile, solution.

Ultimately, recognizing that a solid Teflon O-ring behaves like a rigid gasket, not a flexible seal, is the key to preventing costly application failures.

Summary Table:

| Disadvantage | Impact on Performance |

|---|---|

| Lack of Elasticity | Poor compression sealing; unforgiving to hardware imperfections. |

| Cold Flow (Creep) | Permanent deformation under pressure, leading to loss of sealing force. |

| Difficult Installation | Requires precise grooves; risk of damage during assembly. |

| High Thermal Expansion | Seal can loosen or extrude with temperature changes. |

Struggling with sealing performance in demanding environments? KINTEK specializes in manufacturing high-precision PTFE components, including custom O-rings and seals. We understand the critical balance between chemical resistance and mechanical reliability. Our experts can help you select or design the right sealing solution—from prototypes to high-volume production—ensuring optimal performance for your application in the semiconductor, medical, laboratory, and industrial sectors. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is a PTFE rotary shaft lip seal and what is its primary function? Superior Sealing for Demanding Applications

- What is the temperature range for PTFE spacer rings? A Guide to Extreme Thermal Stability

- What are the key advantages of PTFE oil scraper rings? Superior Sealing, Low Friction & Durability

- How is Teflon used in the semiconductor industry? Essential for High-Purity Manufacturing

- How are Teflon bushings used in the automotive industry? For Superior Performance and Maintenance-Free Operation

- What temperature range can PTFE encapsulated O-rings withstand? -60°C to 205°C, Depending on Core

- What properties of PTFE seals contribute to extending the service life of ball valves? Achieve Long-Term Reliability

- What temperature range can Virgin Molded PTFE withstand? From Cryogenic to High-Heat Performance