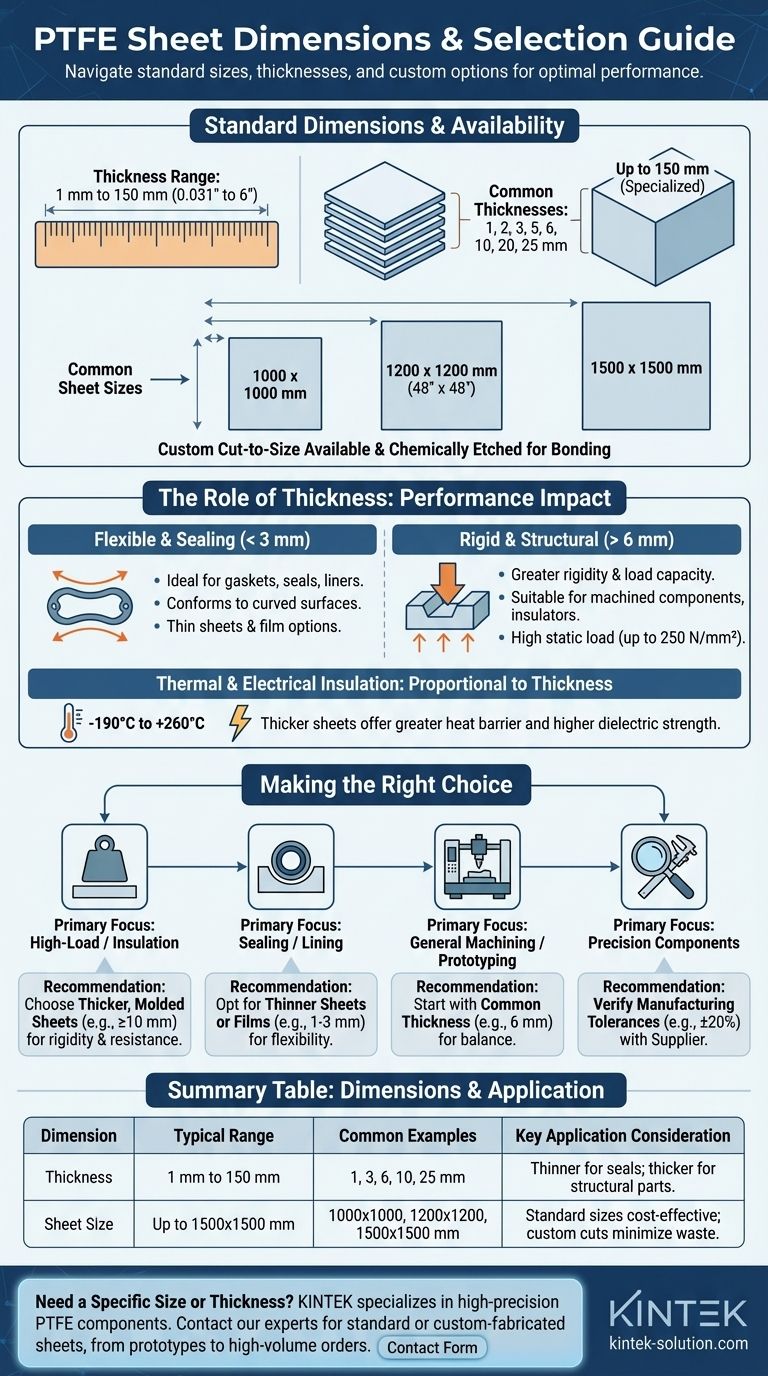

For engineers and designers, understanding the available dimensions of PTFE sheets is the first step in material selection. Standard PTFE sheets are commonly available in thicknesses ranging from approximately 1 mm (0.031 inches) up to 150 mm (around 6 inches), with common sheet sizes including 1000x1000 mm, 1200x1200 mm (48x48 inches), and 1500x1500 mm. For applications requiring thinner material, PTFE is available as film or foil.

While standard sizes offer immediate availability, the true value of PTFE lies in its customizability. The core challenge is not just finding a size that fits, but selecting a thickness that delivers the required mechanical, thermal, and electrical performance for your specific application.

Deconstructing PTFE Sheet Dimensions

Understanding the typical offerings from suppliers helps streamline the procurement process. PTFE is generally categorized by thickness and the manufacturing method used to produce it.

Standard Thickness Range

PTFE sheets are available across a very wide thickness spectrum. Thinner sheets (typically under 6 mm) are often "skived" from a larger billet, while thicker blocks are compression molded.

Commonly stocked thicknesses include 1 mm, 2 mm, 3 mm, 5 mm, 6 mm, 10 mm, 20 mm, and 25 mm, with availability extending up to 150 mm for specialized applications requiring large, solid blocks.

Common Sheet Sizes

To facilitate handling and shipping, manufacturers produce large master sheets. The most prevalent standard sizes you will encounter are:

- 1000 mm x 1000 mm

- 1200 mm x 1200 mm (approximately 48" x 48")

- 1500 mm x 1500 mm

These large formats serve as the base material that is then cut down for specific jobs.

The Role of Customization

Nearly all suppliers offer cut-to-size services. This is a crucial feature, as it allows you to order pieces that precisely match your design, minimizing waste and post-processing. For applications requiring adhesion, sheets can also be ordered with one side chemically etched to make the inert surface bondable.

Why Thickness Is More Than Just a Dimension

The thickness you choose directly impacts the material's performance characteristics. This decision goes far beyond simply filling a physical space.

Mechanical Strength and Load Capacity

Thicker PTFE sheets provide greater rigidity and can withstand higher compressive loads without deforming. The material has a high static load capacity (up to 250 N/mm²), and increasing the thickness ensures this strength is translated into structural stability for components like bearing pads or support blocks.

Thermal and Electrical Insulation

PTFE has an exceptionally wide operating temperature range (-190°C to +260°C) and is an excellent electrical insulator. The effectiveness of this insulation is directly proportional to thickness. A thicker sheet will provide a greater barrier to heat transfer and offer higher dielectric strength for high-voltage applications.

Flexibility vs. Rigidity

The choice between flexibility and rigidity is a primary function of thickness.

- Thin sheets (< 3 mm): Are flexible and ideal for gaskets, seals, and liners that must conform to curved or irregular surfaces.

- Thick sheets (> 6 mm): Are rigid and self-supporting, making them suitable for machined components, insulators, and structural parts.

Understanding the Trade-offs and Tolerances

While versatile, working with PTFE requires an awareness of its manufacturing realities and inherent properties.

Manufacturing Tolerances

PTFE parts are manufactured to specific tolerances that can be significant. For example, some products may have a thickness tolerance of ±20% or more. If your application requires high precision, you must verify the exact dimensional tolerances with your supplier before ordering.

Cost and Availability

Standard sheet sizes and common thicknesses are the most economical and readily available options. Opting for extremely thick sheets, custom-cut dimensions, or specialized treatments like chemical etching will increase both the cost and lead time.

Surface Properties and Bonding

Virgin PTFE has an extremely low coefficient of friction and is chemically inert, making it almost impossible to bond with conventional adhesives. If your design requires bonding PTFE to another substrate, specifying a chemically etched surface is non-negotiable.

Making the Right Choice for Your Application

Select your PTFE sheet dimensions based on the primary goal of your component.

- If your primary focus is high-load support or insulation: Choose thicker, molded sheets (e.g., 10 mm or greater) for maximum rigidity and thermal/electrical resistance.

- If your primary focus is sealing or lining: Opt for thinner, skived sheets or films (e.g., 1 mm to 3 mm) that offer the necessary flexibility to conform to surfaces.

- If your primary focus is general-purpose machining or prototyping: Start with a common thickness like 6 mm in a standard sheet size, which provides a good balance of rigidity and machinability.

- If your primary focus is precision components: Confirm the supplier's specific manufacturing tolerances before purchasing material to ensure it meets your design's requirements.

By aligning your dimensional choice with the material's core properties, you can engineer a solution that fully leverages the unique advantages of PTFE.

Summary Table:

| Dimension | Typical Range | Common Examples | Key Application Consideration |

|---|---|---|---|

| Thickness | 1 mm to 150 mm | 1 mm, 3 mm, 6 mm, 10 mm, 25 mm | Thinner sheets (<3mm) are flexible for seals; thicker sheets (>6mm) are rigid for structural parts. |

| Sheet Size | Up to 1500x1500 mm | 1000x1000 mm, 1200x1200 mm, 1500x1500 mm | Standard sizes are cost-effective; custom cut-to-size minimizes waste. |

Need a PTFE Sheet in a Specific Size or Thickness?

KINTEK specializes in manufacturing high-precision PTFE components—including custom-cut sheets, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure your material's dimensions deliver the required mechanical strength, thermal stability, and electrical insulation for your application.

Contact our experts today for a quote on standard or custom-fabricated PTFE sheets, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Are PTFE slide bearings customizable? Tailor Performance for Your Unique Engineering Challenges

- Why are cold temperatures challenging for seals and how does PTFE overcome these challenges? Master Cryogenic Sealing

- What is the friction coefficient of PTFE bellow seals? Unlock Peak Performance with Low-Friction Seals

- What are the benefits of using Teflon bushings? Achieve Maintenance-Free, High-Performance Operation

- What are the installation advantages of PTFE lined butterfly valves? Simplify Setup & Save on Costs

- What factors influence a PTFE seal's temperature capabilities? Maximize Performance in High-Heat Applications

- How is PTFE used in the automotive industry? Enhancing Vehicle Reliability and Performance

- Are PTFE diaphragms suitable for all chemical environments? The Critical Limits You Must Know