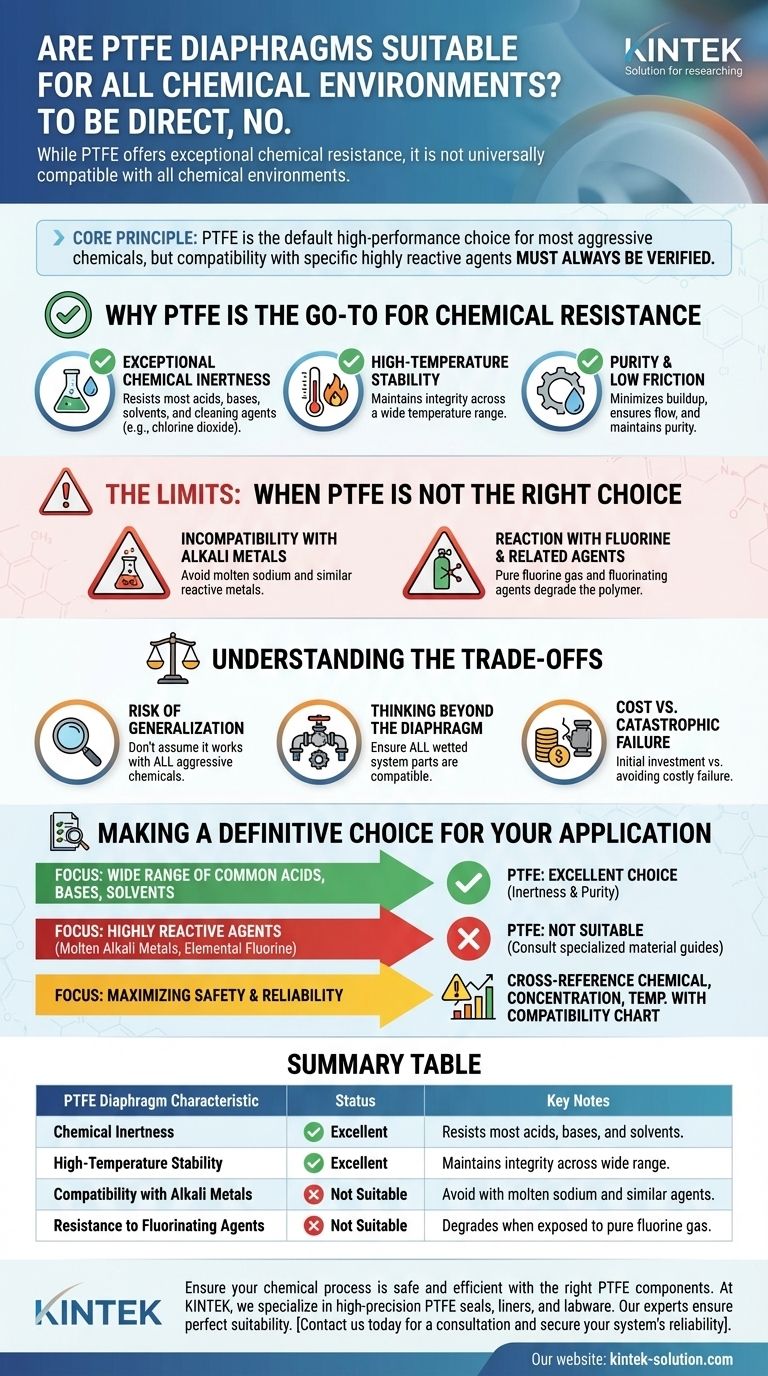

To be direct, no. While Polytetrafluoroethylene (PTFE) offers exceptional chemical resistance and is suitable for a vast range of applications, it is not universally compatible with all chemical environments. Certain highly reactive substances can degrade PTFE, making careful material selection essential for safety and operational integrity.

The core principle is this: PTFE should be considered the default high-performance choice for most aggressive chemical applications, but its known incompatibility with a specific class of highly reactive agents means you must always verify its suitability for your exact chemical environment.

Why PTFE is the Go-To for Chemical Resistance

PTFE's reputation as a chemically robust material is well-earned. Its unique molecular structure gives it properties that make it ideal for diaphragms in demanding systems like pumps and valves.

Exceptional Chemical Inertness

The primary advantage of PTFE is its chemical inertness. It does not react with the vast majority of industrial chemicals, including aggressive acids, bases, solvents, and cleaning agents like chlorine dioxide. This prevents contamination of the process fluid and degradation of the diaphragm itself.

High-Temperature Stability

PTFE maintains its integrity across a wide range of temperatures. This allows it to be used in processes that involve significant heat without compromising its chemical resistance or structural form.

Purity and Low Friction

The smooth, low-friction surface of a PTFE diaphragm minimizes the risk of material buildup or contamination. This ensures consistent flow control, reduces operational friction, and helps maintain the purity of the medium being processed.

The Limits: When PTFE Is Not the Right Choice

Despite its strengths, PTFE has specific, well-documented vulnerabilities. Ignoring these limitations can lead to equipment failure, leakage, and hazardous situations.

Incompatibility with Alkali Metals

PTFE is not compatible with certain alkali metals, particularly in their molten state (e.g., sodium). These reactive metals can attack the fluorine-carbon bond that gives PTFE its stability.

Reaction with Fluorine and Related Agents

Pure fluorine gas and other highly reactive fluorinating agents are among the few chemicals that can chemically attack PTFE. These substances can degrade the polymer, compromising the diaphragm's integrity.

Understanding the Trade-offs

Choosing a diaphragm material is not just about chemical compatibility; it's about a complete risk assessment. An incomplete analysis can lead to costly and dangerous errors.

The Risk of Generalization

Never assume PTFE is suitable just because it works with "most" aggressive chemicals. The failure point is always the specific chemical it doesn't work with. The cost of a failure far outweighs the effort of verification.

Thinking Beyond the Diaphragm

A PTFE diaphragm is only one component in a valve or pump. While it may be resistant, you must ensure all other wetted parts of the system are also compatible with the process fluid to prevent a different point of failure.

Cost vs. Catastrophic Failure

While PTFE components may represent a higher initial investment, they often provide a lower total cost of ownership through reduced maintenance and downtime. However, using it in an incompatible application erases all benefits and introduces significant risk.

Making a Definitive Choice for Your Application

Use the following guidelines to ensure you select the correct material for your specific operational goal.

- If your primary focus is handling a wide range of common acids, bases, and solvents: PTFE is an excellent and highly reliable choice for ensuring chemical inertness and system purity.

- If your primary focus is working with highly reactive agents like molten alkali metals or elemental fluorine gas: You must explicitly avoid PTFE and consult specialized material guides for a suitable alternative.

- If your primary focus is maximizing safety and operational reliability: Always cross-reference your specific chemical, its concentration, and operating temperature with a trusted chemical compatibility chart before finalizing your decision.

Ultimately, informed material selection is the foundation of a safe and efficient chemical processing system.

Summary Table:

| PTFE Diaphragm Characteristic | Status | Key Notes |

|---|---|---|

| Chemical Inertness | Excellent | Resists most acids, bases, and solvents. |

| High-Temperature Stability | Excellent | Maintains integrity across a wide temperature range. |

| Compatibility with Alkali Metals | Not Suitable | Avoid with molten sodium and similar agents. |

| Resistance to Fluorinating Agents | Not Suitable | Degrades when exposed to pure fluorine gas. |

Ensure your chemical process is safe and efficient with the right PTFE components.

At KINTEK, we specialize in manufacturing high-precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your diaphragms and other components are perfectly suited to your specific chemical environment, preventing costly failures and ensuring operational integrity.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and compatibility. Don't risk equipment failure—let our experts help you select or design the ideal PTFE solution.

Contact us today for a consultation and secure your system's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability