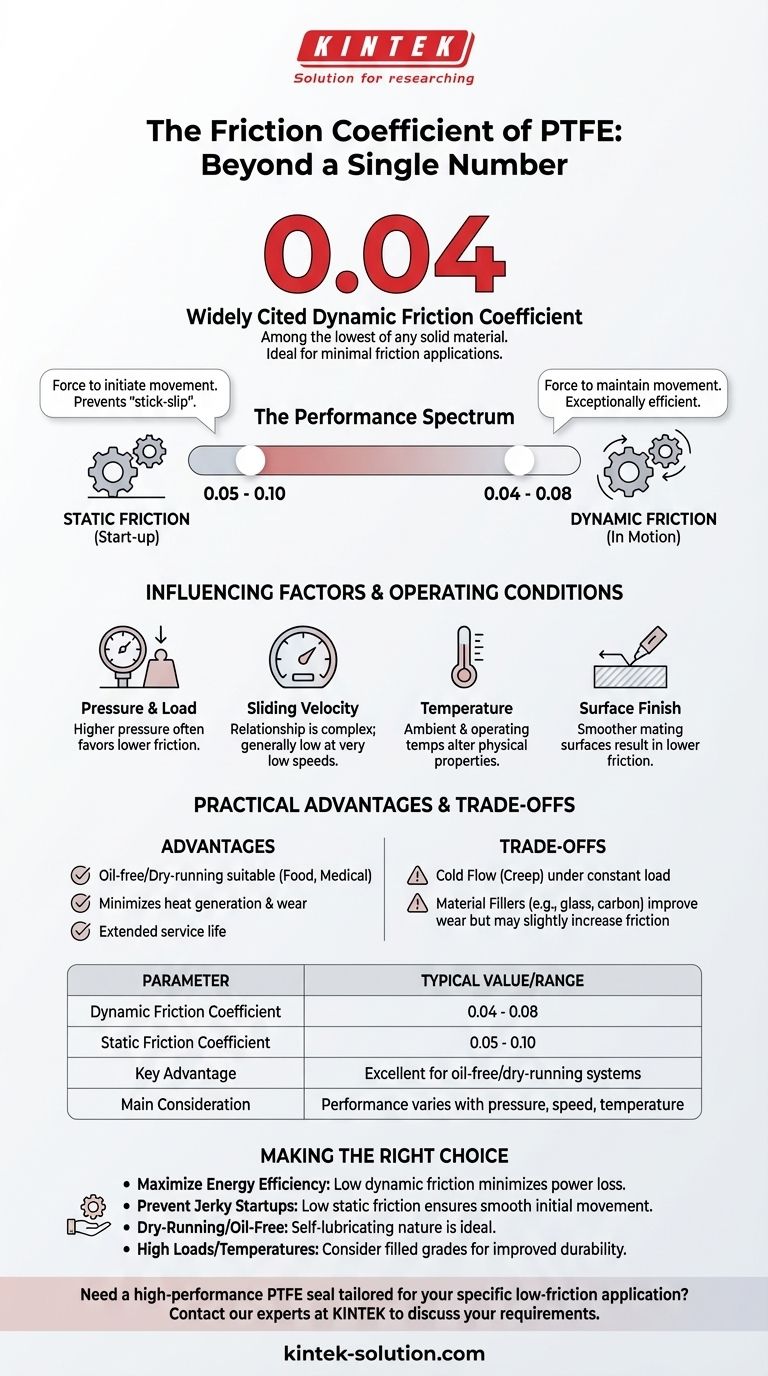

The widely cited dynamic friction coefficient of PTFE bellow seals is 0.04, which is among the lowest of any solid material. This exceptionally low value is why PTFE is a default choice for applications requiring minimal friction, especially in oil-free or dry-running conditions. However, this single number represents an ideal state and does not tell the whole story.

The friction coefficient of PTFE is not a single constant but a range that depends on real-world operating conditions. Understanding that its true performance is influenced by factors like pressure, speed, and temperature is critical for proper material selection and system design.

Why a Single Number Is Misleading

The idea of a single friction coefficient is a simplification. For a material like PTFE, it's more accurate to think of a performance spectrum that changes based on how it's used.

Static vs. Dynamic Friction

A key distinction is whether the components are at rest or in motion.

Static friction is the force required to initiate movement from a standstill. For PTFE, this typically ranges from 0.05 to 0.10.

Dynamic friction (or kinetic friction) is the force required to maintain movement. This is where PTFE truly excels, with a value as low as 0.04 to 0.08.

This low dynamic value is what makes PTFE so efficient, while the small difference between static and dynamic values prevents the "stick-slip" phenomenon common in other materials upon startup.

The Impact of Operating Conditions

Several environmental and operational factors directly influence the friction of a PTFE seal.

Pressure and Load: Higher pressure and load generally favor a lower friction coefficient in PTFE seals. The material's structure responds to the force in a way that reduces resistance.

Sliding Velocity: The relationship with speed is more complex. Extremely low velocities (under 10 ft/min) tend to maintain a low friction coefficient, but this can change as speeds increase.

Temperature: Both ambient and operating temperatures can alter the physical properties of PTFE, which in turn affects its frictional characteristics.

Surface Finish: The smoothness and hardness of the mating surface play a significant role. A smoother, properly finished surface will result in lower friction.

The Practical Advantage of Low Friction

The exceptional anti-friction properties of PTFE provide tangible engineering benefits.

It is one of the few materials suitable for no-oil or low-oil operation, making it ideal for food, medical, or cleanroom applications.

This characteristic also minimizes friction-related heat generation and wear, extending the service life of both the seal and the components it touches.

Understanding the Trade-offs

While its low friction is a significant advantage, PTFE is not a perfect material for every scenario. An objective assessment requires acknowledging its limitations.

Cold Flow (Creep)

PTFE is a relatively soft material. Under a constant load, especially at elevated temperatures, it can slowly deform over time in a process known as creep or "cold flow." This must be accounted for in the design of the seal gland.

Material Fillers

To counteract creep and improve wear resistance, pure PTFE is often blended with fillers like glass, carbon, or bronze. These fillers enhance mechanical properties but can also slightly increase the coefficient of friction compared to virgin PTFE.

Making the Right Choice for Your Application

Selecting the right seal requires matching the material's properties to your primary goal.

- If your primary focus is maximum energy efficiency: The low dynamic friction coefficient of PTFE minimizes power loss in rotating or sliding systems.

- If your primary focus is preventing jerky startups: PTFE's low static friction ensures smooth initial movement, even after prolonged shutdowns.

- If your primary focus is a dry-running or oil-free system: PTFE's self-lubricating nature makes it one of the best possible choices.

- If your primary focus is high loads or temperatures: Consider a filled grade of PTFE to gain improved creep resistance and durability, accepting a potential minor trade-off in friction.

By accounting for your specific operating environment, you can fully leverage the exceptional low-friction properties of PTFE.

Summary Table:

| Parameter | Typical Value/Range for PTFE Seals |

|---|---|

| Dynamic Friction Coefficient | 0.04 - 0.08 |

| Static Friction Coefficient | 0.05 - 0.10 |

| Key Advantage | Excellent for oil-free/dry-running systems |

| Main Consideration | Performance varies with pressure, speed, and temperature |

Need a high-performance PTFE seal tailored for your specific low-friction application?

At KINTEK, we specialize in manufacturing precision PTFE components, including bellow seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a seal that delivers optimal performance by accounting for your exact operating conditions—from prototypes to high-volume orders.

Contact our experts today to discuss your requirements and leverage our custom fabrication capabilities for superior efficiency and reliability.

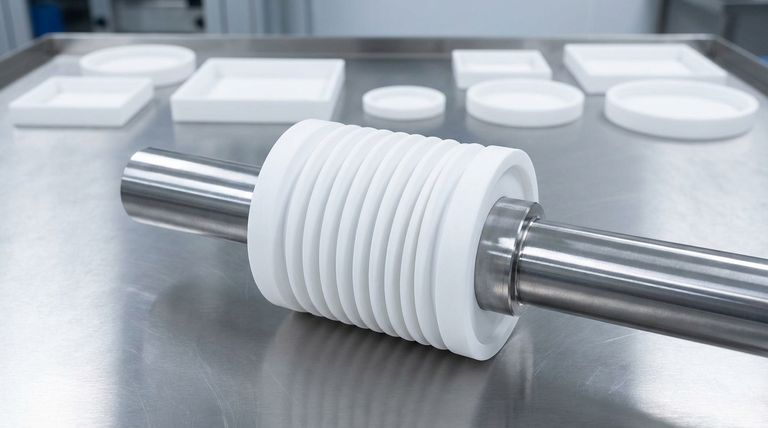

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Which industries or applications benefit from PTFE seals and rings? Solve Extreme Sealing Challenges

- What makes PTFE plugs durable? Unmatched Chemical and Temperature Resistance

- What are the benefits of using custom Teflon parts for clients? Reduce Costs & Boost Reliability

- What are the most popular and processed forms of PTFE materials? A Guide to Rods, Tubes, Sheets & Tapes

- How are Teflon rods applied in the automotive and aerospace industries? Solve Friction, Heat, and Chemical Challenges

- Why are PTFE gaskets important in systems with varying temperatures? Ensure Leak-Proof Sealing from Cryogenic to High Heat

- Why is virgin PTFE preferred for custom parts? Unmatched Purity for Critical Applications

- How does Reinforced PTFE differ from Virgin PTFE? Unlock the Right Material for Your Application