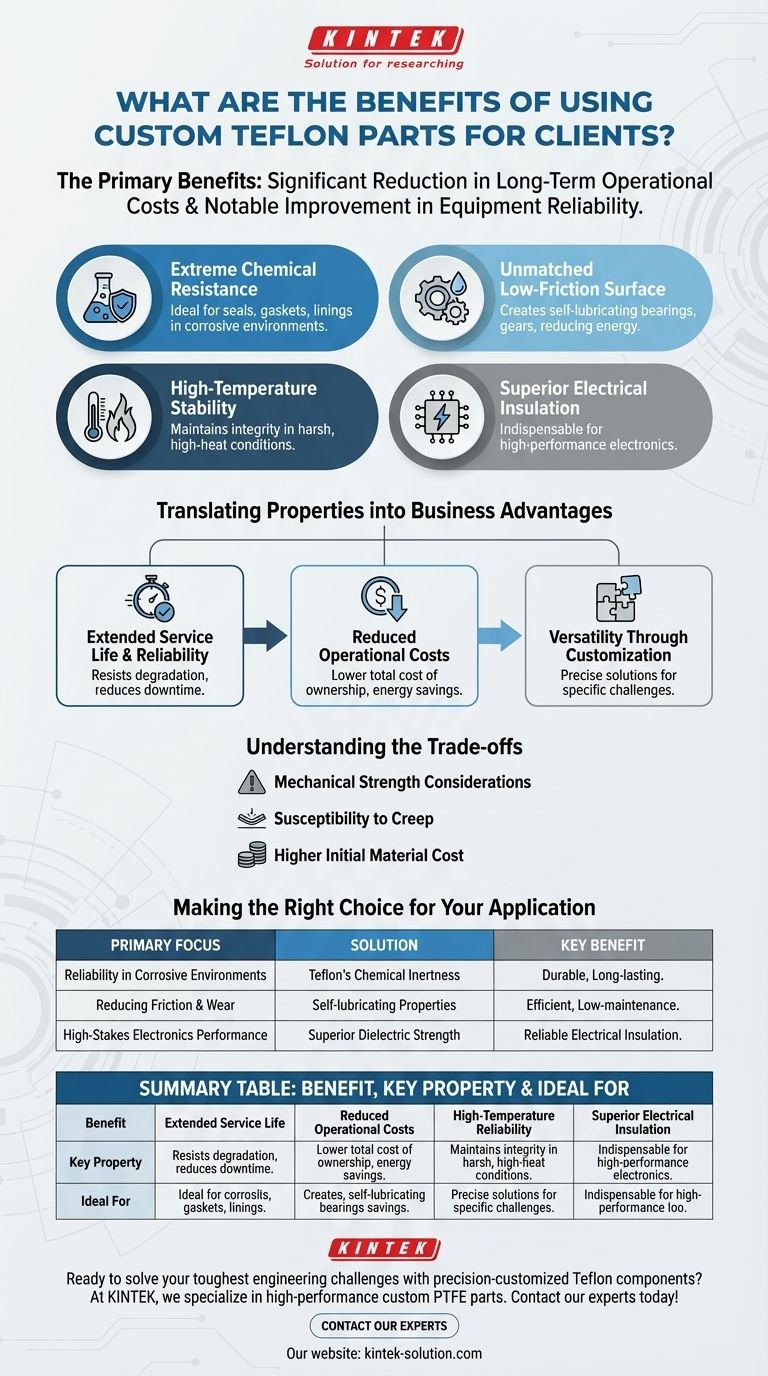

The primary benefits of using custom Teflon parts are a significant reduction in long-term operational costs and a notable improvement in equipment reliability. These advantages stem directly from Teflon's inherent high-performance properties, which allow components to last longer and function more effectively, especially in demanding environments.

Customizing parts from a high-performance material like Teflon is not just a component upgrade; it's a strategic investment in operational stability. The goal is to move beyond frequent replacements and maintenance cycles by engineering a solution that is perfectly matched to its specific, challenging application.

The Core Properties That Drive Performance

The business advantages of Teflon (PTFE) are a direct result of its unique molecular structure. Understanding these foundational properties explains why it is a superior choice for specific critical applications.

Extreme Chemical Resistance

Teflon is exceptionally inert and resistant to nearly all industrial chemicals, acids, and bases. This makes it an ideal material for seals, gaskets, and linings in chemical processing and laboratory equipment.

Unmatched Low-Friction Surface

Teflon possesses one of the lowest coefficients of friction of any solid material. This property is crucial for creating self-lubricating bearings, gears, and slide plates that reduce energy consumption and eliminate the need for external lubricants.

High-Temperature Stability

Teflon parts maintain their integrity and performance across a wide range of temperatures. They can operate effectively in harsh, high-heat conditions where many other plastics would degrade or fail.

Superior Electrical Insulation

With excellent dielectric properties, Teflon is a superb electrical insulator. This makes it indispensable in the electronics industry for high-performance insulators, connectors, and components for circuit boards.

Translating Properties into Business Advantages

These inherent characteristics translate directly into measurable improvements for any operation that relies on high-performance components.

Extended Service Life and Reliability

Because Teflon resists chemical attack, heat degradation, and wear, custom parts made from it last significantly longer than those made from conventional materials. This directly reduces equipment downtime and the frequency of costly part replacements.

Reduced Operational Costs

The extended lifespan and low-maintenance nature of Teflon parts lead to a lower total cost of ownership. Its low-friction surface can also reduce the energy required to operate machinery, contributing to further cost savings.

Versatility Through Customization

The ability to machine Teflon into custom shapes means its benefits can be applied to solve very specific engineering challenges. A custom-designed part ensures a perfect fit and maximizes the material's performance for a unique application.

Understanding the Trade-offs

While highly effective, Teflon is not a universal solution. An objective assessment requires acknowledging its limitations to ensure it is applied correctly.

Mechanical Strength Considerations

Compared to some specialized engineering plastics, Teflon is relatively soft and has lower tensile strength. It is generally not suitable for high-load structural applications where mechanical rigidity is the primary requirement.

Susceptibility to Creep

Under a constant, sustained load, Teflon can be prone to "creep," or slow deformation over time. This must be a design consideration for components that will be under continuous mechanical stress.

Higher Initial Material Cost

The initial procurement cost of Teflon is higher than that of common plastics like nylon or polyethylene. The investment is justified by its long service life and reduced maintenance costs, but the upfront expense must be factored into budget decisions.

Making the Right Choice for Your Application

To determine if custom Teflon parts are the correct solution, align the material’s strengths with your primary operational goal.

- If your primary focus is reliability in corrosive environments: Teflon's unmatched chemical inertness provides the most durable and long-lasting solution.

- If your primary focus is reducing friction and mechanical wear: Its self-lubricating properties are ideal for creating highly efficient, low-maintenance moving parts.

- If your primary focus is performance in high-stakes electronics: Teflon's superior dielectric strength ensures reliable electrical insulation for critical components.

Ultimately, choosing a custom Teflon part is a decision to engineer a precise solution for a difficult problem, prioritizing long-term performance over short-term cost.

Summary Table:

| Benefit | Key Property | Ideal For |

|---|---|---|

| Extended Service Life | Extreme Chemical Resistance | Chemical processing, lab equipment |

| Reduced Operational Costs | Low-Friction & Self-Lubricating | Bearings, gears, slide plates |

| High-Temperature Reliability | High-Temperature Stability | Harsh, high-heat environments |

| Superior Electrical Insulation | Excellent Dielectric Properties | Electronics, circuit boards |

Ready to solve your toughest engineering challenges with precision-customized Teflon components?

At KINTEK, we specialize in manufacturing high-performance custom PTFE parts—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a part perfectly engineered for your application, maximizing reliability and minimizing your total cost of ownership.

Contact our experts today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the mechanical, thermal, and electrical properties of PTFE sheets? The Ultimate Guide to Performance

- What industries commonly use Teflon machined parts and why? Achieve Unmatched Performance in Demanding Environments

- What are the properties of Modified Polytetrafluoroethylene? Enhanced Performance for Demanding Applications

- How does surface finish impact PTFE sheet performance? A Guide to Optimizing for Your Application

- Why are PTFE seals preferred in press machinery in the pharmaceutical industry? Ensuring Purity and Performance

- What are the overall benefits of using PTFE expansion bellows? Prevent Pipe Failure and Reduce Downtime

- What types of industrial applications are Teflon Bellow Mechanical Seals best suited for? Excel in Harsh Chemical & High-Speed Environments

- What factors should be considered when choosing between spiral and split PTFE backup rings?