At its core, Polytetrafluoroethylene (PTFE) is a material of extremes. Its properties are not merely "good"; they are often best-in-class, particularly its exceptional thermal stability, chemical inertness, and electrical insulation. Mechanically, it is defined by an incredibly low coefficient of friction, making it one of the most slippery materials known.

PTFE is an elite performance polymer offering an unparalleled combination of thermal, chemical, and electrical properties. However, its primary design consideration is mechanical: its exceptional flexibility and low friction come at the cost of low stiffness and a tendency to deform under sustained load, a phenomenon known as creep.

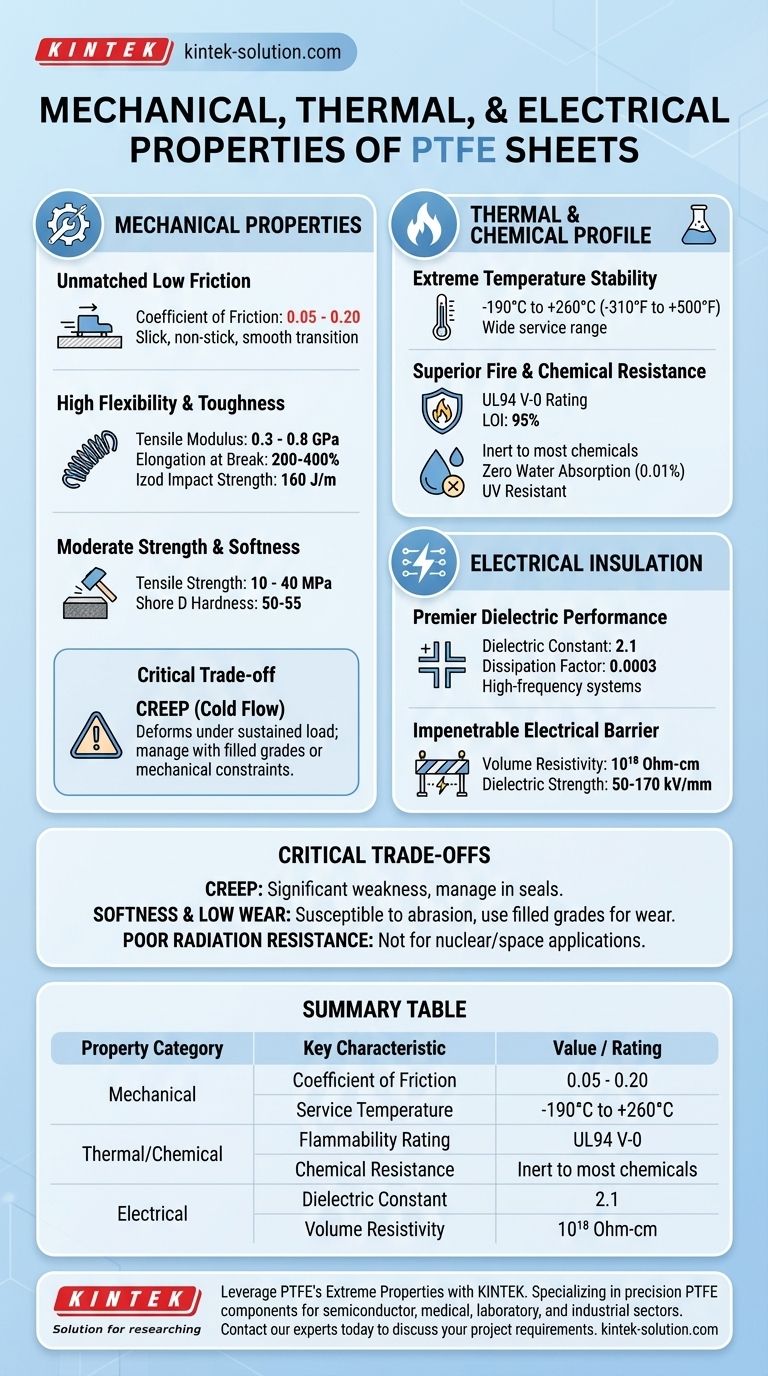

A Deep Dive into Mechanical Properties

The mechanical behavior of PTFE is a story of trade-offs between slipperiness, flexibility, and strength. Understanding this balance is critical for any successful application.

Unmatched Low Friction

PTFE's most famous characteristic is its extremely low coefficient of friction (0.05 - 0.20). This gives it a slick, non-stick surface comparable to wet ice on wet ice.

Crucially, its static and dynamic friction coefficients are nearly identical. This prevents "stick-slip" behavior, ensuring a smooth transition from a standstill to motion, which is vital for precision bearings and sliding components.

High Flexibility and Toughness

PTFE is not a rigid material. It has a very low tensile modulus (0.3 - 0.8 GPa), which makes it highly flexible.

This flexibility is paired with a very high elongation at break (200-400%) and good Izod impact strength (160 J/m). In simple terms, PTFE can be bent and stretched significantly without breaking and can absorb impacts well.

Moderate Strength and Softness

PTFE's tensile strength is moderate, typically ranging from 10 to 40 MPa. It is not intended for use as a primary structural material that must bear heavy loads.

It is also a relatively soft material, with a Shore D hardness of 50-55. This softness contributes to its excellent sealing capabilities but also makes it susceptible to scratching and abrasion.

Unpacking the Thermal and Chemical Profile

PTFE’s stability across extreme temperatures and harsh chemical environments is a primary reason for its selection in demanding industries.

Extreme Temperature Stability

PTFE maintains its properties over an exceptionally wide service temperature range, from cryogenic conditions at -190°C (-310°F) up to +260°C (500°F).

This thermal resilience allows it to be used in applications from aerospace components to high-temperature industrial seals where other polymers would fail.

Superior Fire and Chemical Resistance

PTFE is exceptionally non-flammable, carrying a UL94 V-0 rating and a very high Limiting Oxygen Index (LOI) of 95%. It will self-extinguish almost immediately upon removal of a flame source.

Furthermore, it is chemically inert to nearly all industrial chemicals and solvents, and it exhibits excellent resistance to UV degradation and has virtually zero water absorption (0.01%).

Excellence in Electrical Insulation

For electrical applications, PTFE is one of the highest-performing insulators available, especially for high-frequency systems.

Premier Dielectric Performance

PTFE has a very low dielectric constant (2.1) and an extremely low dissipation factor (0.0003).

This combination means it stores very little electrical energy and loses minimal energy as heat when exposed to an alternating electric field. This makes it a top-tier choice for high-frequency cable insulation and printed circuit boards (PCBs) used in RF and microwave applications.

Impenetrable Electrical Barrier

With an extremely high volume resistivity (10¹⁸ Ohm-cm) and dielectric strength (50-170 kV/mm), PTFE is a phenomenal electrical insulator. It effectively stops the flow of electric current, preventing short circuits and ensuring signal integrity.

Understanding the Critical Trade-offs

No material is perfect. To use PTFE effectively, you must design around its inherent limitations.

The Challenge of Creep (Cold Flow)

This is PTFE's most significant mechanical weakness. Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

For applications like gaskets and seals, constant pressure can cause the PTFE to slowly "flow" out of position, leading to a loss of sealing force over time. This can be mitigated by using filled PTFE grades or by incorporating it into designs with mechanical constraints, like bonded rubber cores.

Softness and Low Wear Resistance

While its low friction is an advantage, PTFE's softness means it has relatively low wear resistance. In applications with abrasive media or high-contact-pressure sliding, pure (virgin) PTFE can wear away quickly.

This is often addressed by using filled PTFE grades, which incorporate materials like glass fiber, carbon, or bronze to significantly improve wear resistance and stiffness.

Poor Radiation Resistance

PTFE has poor resistance to high-energy radiation, such as gamma or electron-beam radiation. This exposure can break down the polymer's molecular chains, causing it to become brittle and lose its mechanical properties. This makes it unsuitable for many nuclear and outer space applications.

Choosing PTFE for Your Application

Your final decision must be based on which of PTFE's properties are critical for your success and whether you can mitigate its weaknesses.

- If your primary focus is low-friction sliding or non-stick surfaces: PTFE is an ideal choice, especially where smooth, non-jerking motion is required.

- If your primary focus is high-frequency electrical insulation: PTFE is one of the best materials available due to its low, stable dielectric constant and minimal loss factor.

- If your primary focus is sealing in extreme temperature or chemical environments: PTFE is an excellent candidate, but you must design to manage or contain its tendency to creep under pressure.

- If your primary focus is a high-load structural component: PTFE is unsuitable due to its low strength, low stiffness, and high potential for creep.

By understanding both its exceptional strengths and its critical mechanical limitations, you can effectively leverage PTFE for the most demanding applications.

Summary Table:

| Property Category | Key Characteristic | Value / Rating |

|---|---|---|

| Mechanical | Coefficient of Friction | 0.05 - 0.20 |

| Service Temperature | -190°C to +260°C | |

| Thermal/Chemical | Flammability Rating | UL94 V-0 |

| Chemical Resistance | Inert to most chemicals | |

| Electrical | Dielectric Constant | 2.1 |

| Volume Resistivity | 10¹⁸ Ohm-cm |

Leverage PTFE's Extreme Properties for Your Application

Understanding PTFE's unique balance of strengths and limitations is key to designing high-performance components. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We help you navigate the trade-offs, such as managing creep in seals or enhancing wear resistance with filled compounds, to ensure your application succeeds. From prototypes to high-volume production, our expertise in custom fabrication ensures you get the exact PTFE solution you need.

Ready to design with PTFE? Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are Teflon encapsulated silicone o-rings made of? A Hybrid Seal for Extreme Conditions

- What are the advantages of molybdenum disulfide-filled PTFE? Boost Wear Resistance & Reduce Friction

- What mechanical properties distinguish PTFE O-rings? Master Sealing in Extreme Conditions

- What temperature range can PTFE gaskets and sheets withstand? A Guide from -200°C to +260°C

- What construction industry uses are there for ePTFE sheets? High-Performance Solutions for Durability

- How do PTFE gaskets perform under extreme temperatures? Unlock Reliable Sealing from -200°C to +260°C

- What materials can PTFE balls be made from? Virgin, Modified, or Filled Compounds for Specific Performance

- How does the chemical resistance of PTFE gaskets benefit industrial applications? Achieve Unmatched Reliability