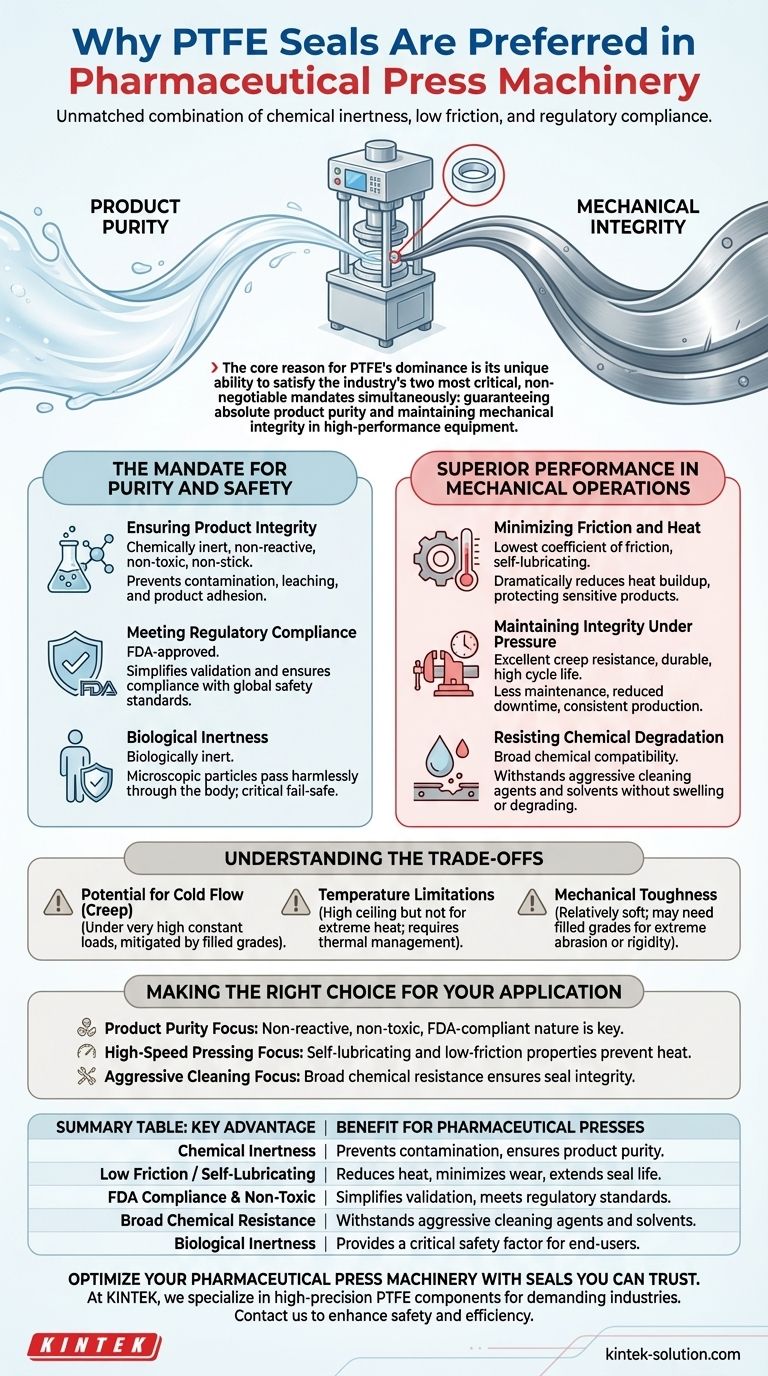

In the pharmaceutical industry, Polytetrafluoroethylene (PTFE) seals are the preferred choice for press machinery due to an unmatched combination of chemical inertness, low friction, and regulatory compliance. These properties ensure that the final product remains pure and uncontaminated while the equipment operates efficiently and reliably under the demanding conditions of repetitive pressing.

The core reason for PTFE's dominance is not just one feature, but its unique ability to satisfy the industry's two most critical, non-negotiable mandates simultaneously: guaranteeing absolute product purity and maintaining mechanical integrity in high-performance equipment.

The Mandate for Purity and Safety

In pharmaceutical manufacturing, preventing contamination is the primary objective. The material chosen for any component that contacts the product must be fundamentally incapable of altering it.

Ensuring Product Integrity

PTFE is chemically inert and non-reactive. This means it will not leach substances into high-purity pharmaceutical compounds or react with active ingredients, preserving the precise chemical composition of the drug.

Its non-toxic and non-stick properties are also critical, preventing product adhesion to the seal surface and ensuring complete transfer and sterility.

Meeting Regulatory Compliance

Regulatory bodies like the FDA have specific guidelines for materials used in drug processing. PTFE is an FDA-approved polymer for these applications, which simplifies the validation process and ensures compliance with global safety standards.

The Advantage of Biological Inertness

Should a microscopic particle of the seal ever wear off, PTFE is biologically inert. This means it can pass through the body without causing a reaction, a critical fail-safe that underpins its use in sterile processing.

Superior Performance in Mechanical Operations

Pharmaceutical presses are high-cycle machines that generate significant friction and stress. The seal material must withstand these mechanical forces without degrading or failing.

Minimizing Friction and Heat

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property is essential in repetitive presses, as it dramatically reduces heat buildup.

Excessive heat can damage the seal, the press machinery, and, most importantly, the temperature-sensitive pharmaceutical product being compressed.

Maintaining Integrity Under Pressure

PTFE exhibits excellent creep resistance, meaning it holds its shape and sealing capability under the constant pressure of a press.

Its durability and high cycle life translate to less frequent maintenance, reduced downtime, and more consistent, cost-effective production runs.

Resisting Chemical Degradation

Pharmaceutical manufacturing often involves aggressive chemicals, including strong oxidizers and acidic or alkaline cleaning agents. PTFE's broad chemical compatibility ensures the seals will not swell, soften, or degrade when exposed to these substances.

Understanding the Trade-offs

While PTFE is a superior material, no single solution is perfect. A clear-eyed technical assessment requires acknowledging its operational limitations.

Potential for Cold Flow (Creep)

While standard PTFE has good creep resistance, under very high, constant loads it can be susceptible to "cold flow," a slow deformation over time. This is often mitigated by using filled grades of PTFE, which incorporate materials like glass, carbon, or bronze to enhance mechanical strength.

Temperature Limitations

PTFE has a well-defined and relatively high-temperature ceiling, but it is not suitable for extreme-heat applications where metals or other specialized polymers might be required. Proper thermal management of the press machinery is still necessary.

Mechanical Toughness

Compared to some engineering plastics or metals, pure PTFE is a relatively soft material. For applications requiring extreme abrasion resistance or structural rigidity, a filled grade or an alternative material may be a more appropriate choice.

Making the Right Choice for Your Application

Selecting the correct seal material is an investment in process stability and product safety. Your primary goal will determine the most important material characteristic.

- If your primary focus is product purity and handling sensitive biologics: The non-reactive, non-toxic, and FDA-compliant nature of PTFE is its most critical advantage.

- If your primary focus is high-speed, repetitive pressing: The self-lubricating and low-friction properties are key to preventing heat buildup and ensuring a long service life.

- If your primary focus is handling aggressive cleaning agents: PTFE's broad chemical resistance ensures seal integrity where other elastomers would quickly fail.

Ultimately, choosing PTFE for pharmaceutical press seals is a decision that prioritizes process reliability, product safety, and regulatory peace of mind.

Summary Table:

| Key Advantage | Benefit for Pharmaceutical Presses |

|---|---|

| Chemical Inertness | Prevents contamination and reaction with active ingredients, ensuring product purity. |

| Low Friction / Self-Lubricating | Reduces heat buildup, minimizes wear, and extends seal life in high-cycle operations. |

| FDA Compliance & Non-Toxic | Simplifies validation and meets strict regulatory standards for drug manufacturing. |

| Broad Chemical Resistance | Withstands aggressive cleaning agents and solvents without degrading. |

| Biological Inertness | Provides a critical safety factor, as any particulate is harmless to the end-user. |

Optimize your pharmaceutical press machinery with seals you can trust.

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom labware, specifically for demanding industries like pharmaceuticals. Our expertise ensures your seals deliver the unmatched purity, low friction, and regulatory compliance your process requires.

Whether you need a prototype or are scaling up to high-volume production, we provide custom fabrication to meet your exact specifications.

Contact KINTEK today to discuss how our PTFE seals can enhance the safety and efficiency of your pharmaceutical pressing operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability