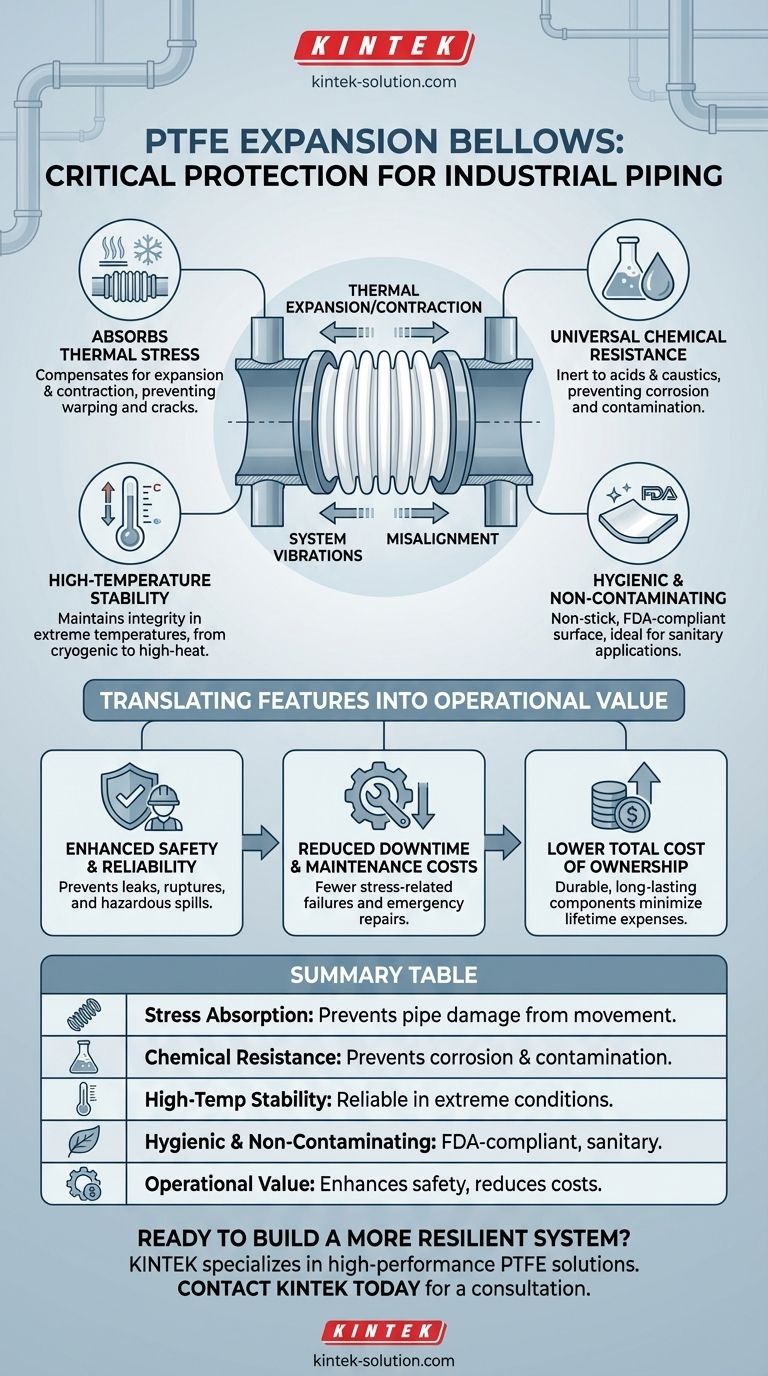

In essence, PTFE expansion bellows serve as critical protective components in industrial piping. They absorb damaging movements, vibrations, and stresses caused by thermal changes and mechanical equipment, while simultaneously offering near-universal resistance to chemical corrosion and high temperatures. This unique combination prevents pipe failure, reduces downtime, and enhances operational safety in demanding environments.

The core problem in any industrial piping system is managing constant, unavoidable stress from temperature, pressure, and vibration. PTFE expansion bellows solve this by providing a point of engineered flexibility that is also exceptionally resilient to the harshest chemical and thermal conditions, protecting the entire system's integrity.

The Core Function: Absorbing Destructive Forces

An industrial piping system is not a static structure. It is a dynamic environment where forces are constantly at play. PTFE bellows are engineered specifically to manage the resulting movement.

Compensating for Thermal Expansion and Contraction

Pipes expand when heated and contract when cooled. Over long distances, this movement generates immense stress that can warp pipes, crack flanges, or damage connected equipment.

A PTFE bellow acts as a flexible joint, compressing and extending to absorb this thermal movement safely.

Dampening System Vibrations

Pumps, motors, and compressors introduce constant vibration into a piping system. Unchecked, this vibration can lead to metal fatigue and connection failures over time.

PTFE bellows isolate these vibrations, preventing them from propagating through the pipeline and protecting sensitive downstream components.

Correcting for Misalignment

Perfect pipe alignment during installation is difficult and expensive to achieve. Forcing misaligned pipes together creates significant residual stress on the system from day one.

A bellow provides a flexible connection that accommodates minor lateral and angular misalignment, neutralizing this built-in stress.

Unmatched Material Advantages of PTFE

While other materials can provide flexibility, Polytetrafluoroethylene (PTFE) offers a combination of properties that makes it uniquely suited for the most challenging applications.

Universal Chemical Resistance

PTFE is chemically inert to nearly all industrial chemicals, acids, and caustics. This prevents the corrosion and degradation that would quickly destroy metal or rubber expansion joints.

This property ensures a long service life and prevents contamination of the process media.

High-Temperature Stability

PTFE maintains its structural integrity and performance characteristics across a wide range of temperatures.

This allows it to be used reliably in systems that experience extreme temperature fluctuations, from cryogenic applications to high-heat processing.

Hygienic and Non-Contaminating Properties

The surface of PTFE is non-adhesive, meaning materials do not stick to it. It is also compliant with FDA standards for sanitary applications.

These features are critical in the pharmaceutical, food, and beverage industries, where preventing contamination and ensuring easy sterilization are paramount.

Translating Features into Operational Value

The technical benefits of PTFE bellows directly translate into significant improvements in safety, reliability, and cost-efficiency.

Enhanced System Reliability and Safety

By proactively absorbing stress, bellows prevent the most common causes of pipe failure: leaks, cracks, and ruptures.

This dramatically reduces the risk of hazardous chemical spills, protecting personnel and the environment.

Reduced Maintenance and Downtime

A system protected by expansion bellows experiences fewer stress-related failures.

This leads to a significant reduction in unplanned downtime, emergency repairs, and overall maintenance costs. The bellow is a cost-effective point of failure compared to the pipe or equipment it protects.

Simplified and Cost-Effective Installation

PTFE bellows are lightweight and flexible, making them far easier and faster to install than rigid, complex piping loops designed to achieve similar flexibility.

This reduces the need for specialized labor and heavy equipment, lowering initial project costs.

Understanding the Trade-offs

While highly effective, PTFE bellows are an engineered component with specific operational limits. Objectivity requires acknowledging their constraints.

Pressure and Temperature Limits

Every PTFE bellow has a defined operating window for pressure and temperature. While its thermal range is broad, it is not limitless and is typically lower than that of metallic bellows. Exceeding these specifications can lead to premature failure.

Susceptibility to Abrasive Media

PTFE is a relatively soft material. In systems transporting abrasive slurries with sharp particles, the bellow's inner surface can be subject to erosion. Specialized liners may be required in these specific cases.

Initial Investment vs. Total Cost of Ownership

The upfront cost of a PTFE expansion bellow can be higher than that of a basic rubber alternative. However, its vastly superior chemical resistance and longer service life in aggressive environments result in a lower total cost of ownership over the system's lifespan.

Making the Right Choice for Your Application

Selecting the right component depends entirely on the primary challenge you need to solve.

- If your primary focus is handling aggressive chemicals: PTFE's near-universal chemical inertness makes it the default and safest choice to prevent corrosion.

- If your primary focus is ensuring process purity and hygiene: The non-stick, FDA-compliant nature of PTFE is non-negotiable for food, beverage, and pharmaceutical applications.

- If your primary focus is maximizing system uptime and mechanical reliability: The ability of a PTFE bellow to absorb thermal movement, vibration, and misalignment is the most direct way to prevent stress-induced failures.

Ultimately, integrating PTFE expansion bellows is a strategic decision to build a more resilient, safe, and cost-effective industrial piping system.

Summary Table:

| Key Benefit | Description |

|---|---|

| Stress Absorption | Compensates for thermal expansion, vibration, and misalignment to prevent pipe damage. |

| Chemical Resistance | Inert to nearly all industrial chemicals, preventing corrosion and contamination. |

| High-Temperature Stability | Maintains performance from cryogenic to high-heat applications. |

| Hygienic & Non-Contaminating | FDA-compliant, non-stick surface ideal for sanitary industries. |

| Operational Value | Enhances safety, reduces unplanned downtime, and lowers total cost of ownership. |

Ready to build a more resilient and cost-effective piping system?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom expansion bellows. Our solutions are engineered to solve the specific challenges faced by the semiconductor, medical, laboratory, and industrial sectors.

Partner with us to:

- Prevent costly failures with bellows that absorb destructive thermal and mechanical stresses.

- Ensure process purity with chemically inert, non-contaminating PTFE.

- Reduce total cost of ownership through durable, long-lasting components that minimize downtime.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your application's demands.

Contact KINTEK today for a consultation and let our expertise protect your critical systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications