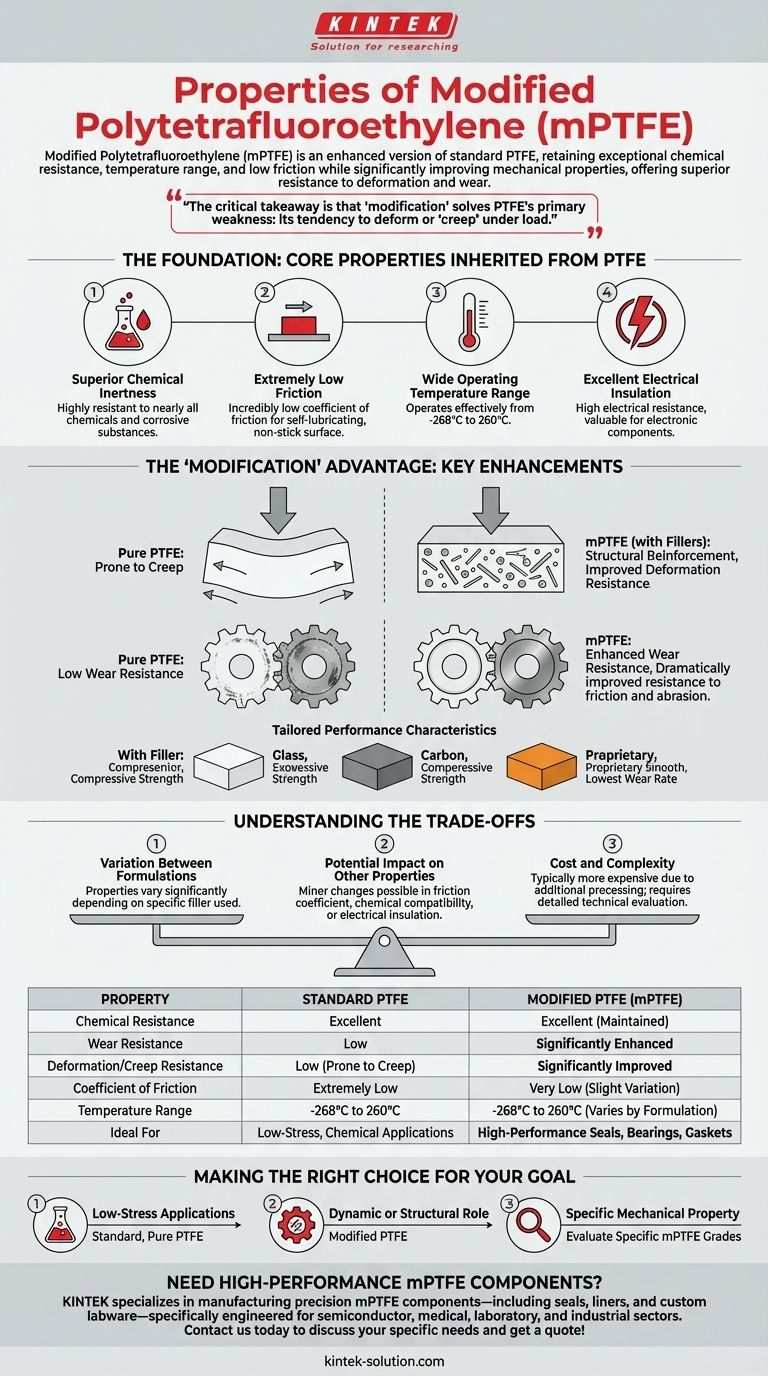

In essence, Modified Polytetrafluoroethylene (mPTFE) is an enhanced version of standard PTFE that retains its exceptional chemical resistance, temperature range, and low friction while significantly improving its mechanical properties. Specifically, it offers superior resistance to deformation and wear, making it suitable for more demanding physical applications where pure PTFE might fail.

The critical takeaway is that "modification" solves PTFE's primary weakness: its tendency to deform or "creep" under load. By adding fillers to the PTFE base, manufacturers create a material ideal for high-performance seals, bearings, and structural components that require both chemical resilience and mechanical integrity.

The Foundation: Core Properties Inherited from PTFE

Modified PTFE begins with the remarkable characteristics of standard Polytetrafluoroethylene, often known by the trade name Teflon. These foundational properties are what make the material family so versatile.

Superior Chemical Inertness

Both standard and modified PTFE are highly resistant to nearly all chemicals and corrosive substances. This makes them ideal for use in aggressive chemical environments where other materials would quickly degrade.

Extremely Low Friction

A defining feature is its incredibly low coefficient of friction, resulting in a self-lubricating, non-stick surface. This is critical for applications involving sliding parts, such as bearings or low-friction seals.

Wide Operating Temperature Range

mPTFE operates effectively across an exceptionally broad temperature spectrum, from cryogenic conditions (-450°F / -268°C) up to high temperatures (500°F / 260°C), while remaining flexible and stable.

Excellent Electrical Insulation

With high electrical resistance, PTFE and its variants are excellent insulators. This property is valuable in a wide range of electrical and electronic components.

The "Modification" Advantage: Key Enhancements

The term "modified" refers to the inclusion of specific fillers in the PTFE matrix. These additives are engineered to overcome the inherent mechanical softness of pure PTFE without compromising its core benefits.

Improved Deformation Resistance

This is the primary reason for choosing mPTFE. Pure PTFE can deform under sustained pressure, a phenomenon known as creep. The fillers in mPTFE provide structural reinforcement, giving it significantly higher resistance to deformation under load.

Enhanced Wear Resistance

The addition of fillers also hardens the material, dramatically improving its resistance to wear from friction and abrasion. Formulations are often rated for wear resistance and are designed to cause very low wear on mating metal surfaces, extending the life of the entire assembly.

Tailored Performance Characteristics

"Modified PTFE" is not a single material but a category. Different fillers (such as glass, carbon, or proprietary organic compounds) create versions with distinct properties. For example, some formulations prioritize compressive strength, while others might be optimized for the lowest possible wear rate.

Understanding the Trade-offs

While modification provides clear mechanical benefits, it's important to recognize the associated trade-offs that come with altering the pure PTFE base.

Variation Between Formulations

The properties of mPTFE can vary significantly depending on the specific filler used. A white-colored formulation may have a wear rating of 3, while an orange, organic-filled version could have a rating of 4 and a different temperature range. You must evaluate the data sheet for the specific grade you are considering.

Potential Impact on Other Properties

Adding a filler can slightly alter other properties. While the goal is to maintain PTFE's core benefits, there could be minor changes to its coefficient of friction, chemical compatibility in very specific scenarios, or its electrical insulating capabilities.

Cost and Complexity

Modified grades are typically more expensive than pure PTFE due to the additional processing and proprietary filler materials involved. The wide variety also means that material selection requires a more detailed technical evaluation.

Making the Right Choice for Your Goal

Selecting the correct material requires matching its properties to the demands of your application.

- If your primary focus is low-stress applications requiring chemical inertness and a non-stick surface: Standard, pure PTFE is often the most suitable and cost-effective choice.

- If your primary focus is performance in a dynamic or structural role like seals, bearings, or gaskets: Modified PTFE is the superior choice due to its critical resistance to deformation and wear.

- If your primary focus is a specific mechanical property like compressive strength or wear rate: You must evaluate specific grades of modified PTFE, as their performance is tailored by the type and amount of filler used.

Ultimately, choosing modified PTFE is a decision to invest in mechanical durability for applications where standard PTFE would be physically inadequate.

Summary Table:

| Property | Standard PTFE | Modified PTFE (mPTFE) |

|---|---|---|

| Chemical Resistance | Excellent | Excellent (Maintained) |

| Wear Resistance | Low | Significantly Enhanced |

| Deformation/Creep Resistance | Low (Prone to Creep) | Significantly Improved |

| Coefficient of Friction | Extremely Low | Very Low (Slight Variation) |

| Temperature Range | -268°C to 260°C | -268°C to 260°C (Varies by Formulation) |

| Ideal For | Low-Stress, Chemical Applications | High-Performance Seals, Bearings, Gaskets |

Need High-Performance mPTFE Components?

Your application demands a material that can handle both harsh chemicals and significant mechanical stress. KINTEK specializes in manufacturing precision mPTFE components—including seals, liners, and custom labware—specifically engineered for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact formulation and performance your project requires.

Contact us today to discuss your specific needs and get a quote! #ContactForm

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications