The choice between spiral and split PTFE backup rings hinges on a critical trade-off between absolute sealing performance and practical installation requirements. Spiral rings offer superior protection in high-pressure, dynamic environments due to their continuous design, while split rings provide good performance with the significant advantage of easier installation and maintenance, especially in equipment that cannot be fully disassembled.

Your decision ultimately comes down to a simple question: Is your application's demand for maximum extrusion resistance high enough to justify a more complex installation process? If not, the convenience of a split ring is often the more practical choice.

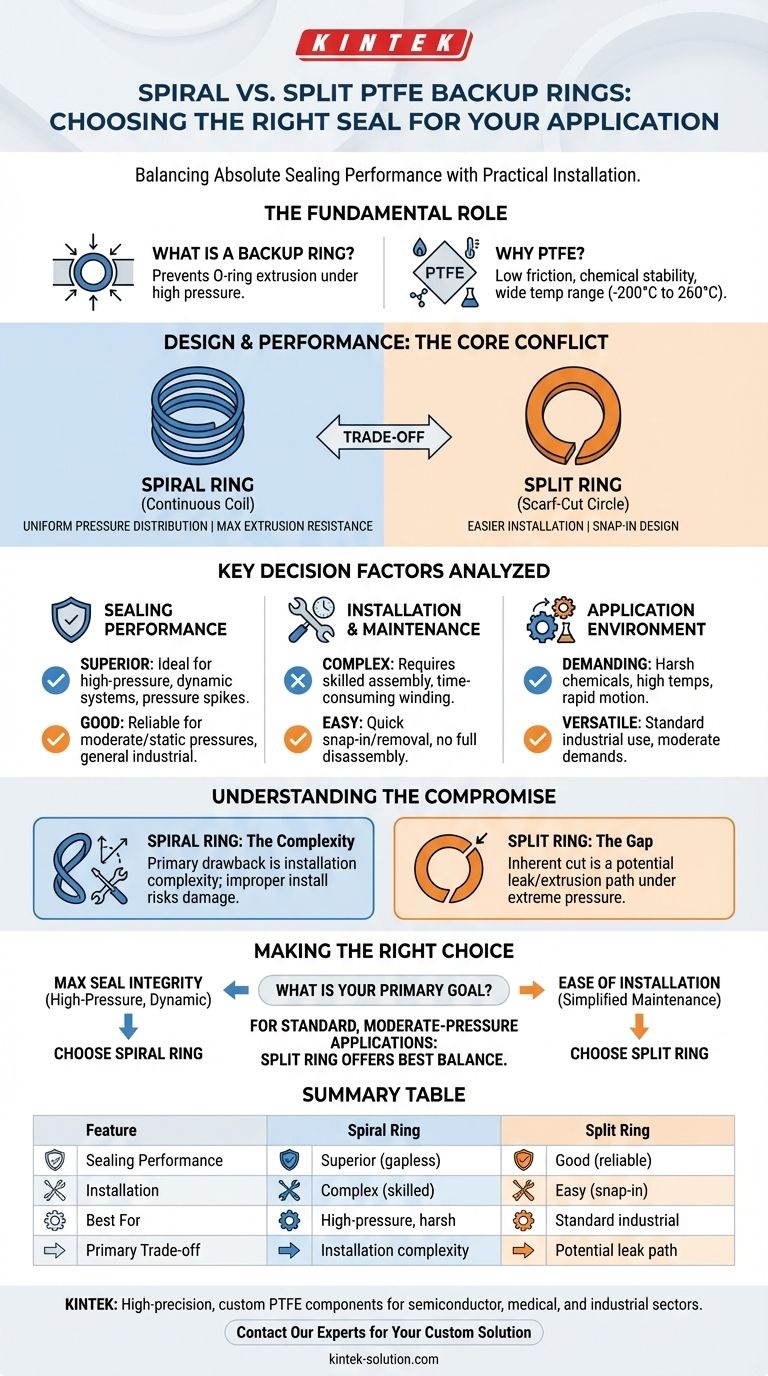

The Fundamental Role of a PTFE Backup Ring

To choose correctly, you must first understand the core function of a backup ring and why Polytetrafluoroethylene (PTFE) is the material of choice.

What is a Backup Ring?

A backup ring is a rigid, supportive device used in conjunction with a softer elastomeric seal, like an O-ring.

Its primary job is to prevent the O-ring from extruding into the clearance gap between mating metal surfaces when subjected to high pressure. This extrusion is a common cause of seal failure.

Why PTFE?

PTFE is an ideal material for this task due to its unique combination of properties.

It has an extremely low coefficient of friction, reducing wear and drag in dynamic applications. It also exhibits outstanding chemical stability and a wide operating temperature range (from -200°C to 260°C), making it suitable for aggressive and demanding environments.

Design and Performance: Spiral vs. Split Rings

The primary difference between the two styles lies entirely in their physical construction, which directly impacts their performance and usability.

The Spiral Ring: A Continuous Coil

A spiral backup ring is constructed from a continuous coil of PTFE wound into a helical shape, similar to a spring.

This continuous, gapless design provides the most uniform pressure distribution against the O-ring. It offers maximum resistance to extrusion because there is no inherent cut or path for the O-ring to squeeze through under pressure.

The Split Ring: A Scarf-Cut Circle

A split backup ring, often called a "scarf cut" ring, is a solid ring that has been cut through at a single point, typically at an angle.

This split allows the ring to be slightly expanded or twisted open. This design dramatically simplifies installation, as it can often be "snapped" into a groove without needing to disassemble the entire component.

Key Decision Factors Analyzed

Your choice will be guided by prioritizing one of the following factors over the other for your specific application.

Sealing Performance

Spiral rings offer excellent, superior sealing performance. They are the preferred choice for high-pressure systems, applications with pressure spikes, and dynamic environments where the risk of extrusion is highest.

Split rings provide good, reliable sealing performance suitable for most general-purpose hydraulic and pneumatic systems with moderate or static pressures. The scarf cut minimizes the gap, but it is still a potential extrusion point under extreme conditions.

Installation and Maintenance

Split rings are exceptionally easy to install and remove. This is their single greatest advantage, facilitating quick assembly, field repairs, and frequent inspections without requiring complete equipment disassembly.

Spiral rings require a more careful and often more difficult installation. The continuous coil must be wound into the groove, which can be time-consuming and requires a skilled technician to avoid twisting or damaging the ring.

Application Environment

Spiral rings are built for the most demanding environments. If your system involves harsh chemicals, high temperatures, or rapid, repetitive motion under high pressure, the robust design of a spiral ring provides the highest margin of safety.

Split rings are highly versatile and are a proven solution for a vast range of standard industrial applications. Their convenience makes them a default choice where extreme pressures are not a primary concern.

Understanding the Trade-offs

There is no universally "better" ring; each comes with a clear compromise.

The Spiral Ring's Compromise: Complexity

The primary drawback of the spiral ring is its installation complexity. An improperly installed ring can be damaged, compromising its ability to function correctly. This adds time and requires a higher skill level during assembly and maintenance.

The Split Ring's Compromise: The Gap

The split ring's inherent weakness is its cut. While the angled scarf cut is designed to ensure the gap closes tightly under pressure, it still represents a potential leak or extrusion path that a continuous spiral ring simply does not have. This risk is small but becomes more significant as system pressure and temperature increase.

Making the Right Choice for Your Application

Use your primary engineering goal to make a clear decision.

- If your primary focus is maximum seal integrity in a high-pressure, dynamic system: Choose the spiral ring for its superior, gapless extrusion resistance.

- If your primary focus is ease of installation and simplified maintenance: Choose the split ring for its convenient design that allows for quick replacement without full disassembly.

- If you are designing for a standard, moderate-pressure application: The split ring offers the best balance of reliable performance and practical convenience.

Ultimately, selecting the right backup ring is about matching the component's design to the true demands of your system.

Summary Table:

| Feature | Spiral Ring | Split Ring |

|---|---|---|

| Sealing Performance | Superior (gapless design) | Good (reliable for moderate pressure) |

| Installation/Maintenance | Complex (requires skilled assembly) | Easy (snap-in, no full disassembly) |

| Best For | High-pressure, dynamic, harsh environments | Standard industrial, moderate-pressure systems |

| Primary Trade-off | Installation complexity | Potential gap/leak path |

Need the Right PTFE Backup Ring for Your Application?

KINTEK specializes in manufacturing high-precision, custom PTFE components—including seals, backup rings, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need the superior performance of a spiral ring or the installation ease of a split ring, we deliver precision production from prototypes to high-volume orders.

Contact our experts today to discuss your requirements and get a solution tailored to your system's demands.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications