Teflon (PTFE) machined parts are mission-critical components in a specific set of high-stakes industries, most notably aerospace, medical, semiconductor manufacturing, and chemical processing. These fields rely on custom-machined Teflon for its unique combination of properties that allow components to function reliably in extreme and demanding environments where other materials would fail.

The widespread adoption of Teflon is not due to a single trait, but its unique combination of extreme chemical inertness, high-temperature tolerance, and an exceptionally low coefficient of friction. This trifecta makes it the default material for engineered parts in environments where performance and purity are non-negotiable.

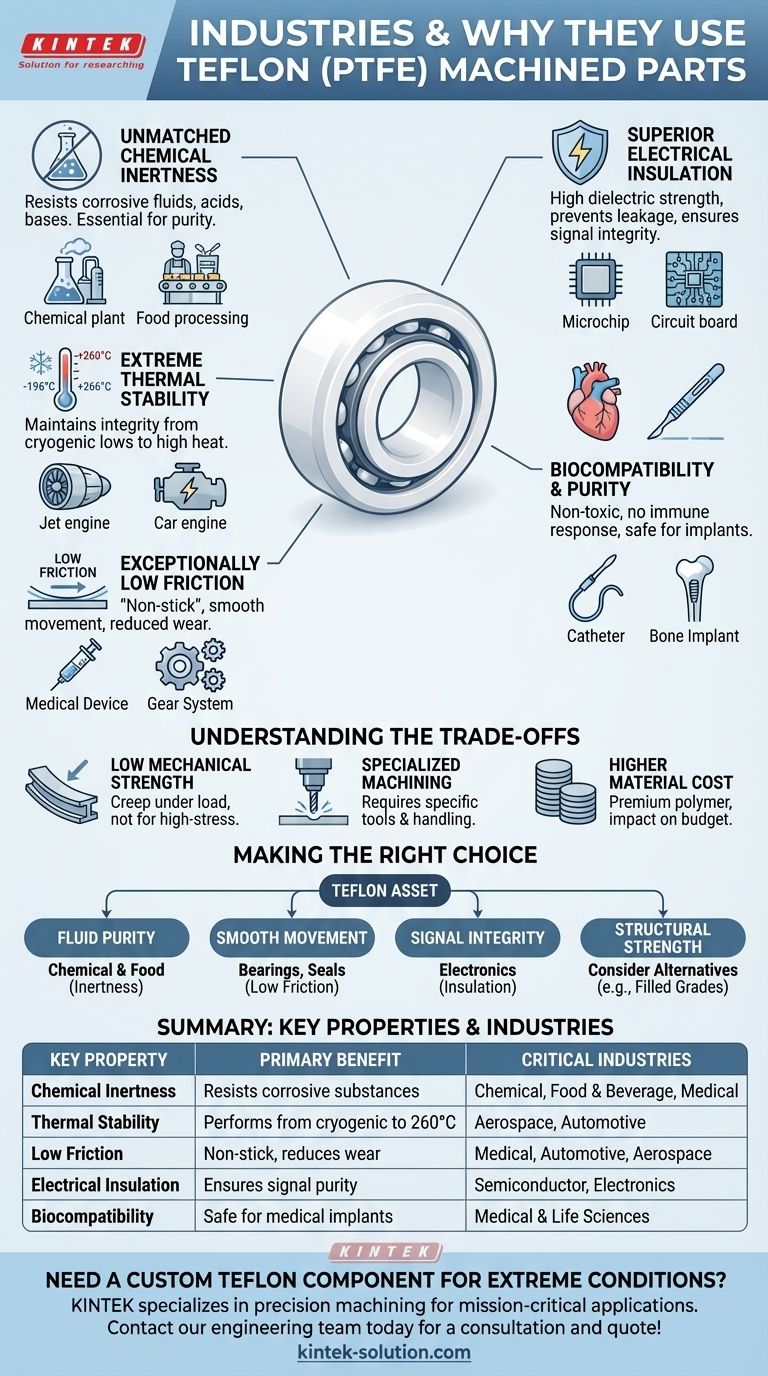

Why These Industries Depend on Teflon

The selection of a material for a critical component is a decision driven by performance requirements. Teflon (polytetrafluoroethylene or PTFE) offers a cluster of high-performance characteristics that align perfectly with the needs of advanced industries.

Unmatched Chemical Inertness

Teflon is famously non-reactive and resistant to nearly all industrial chemicals, acids, and bases. This makes it an essential material for applications involving corrosive fluids.

The chemical processing and food manufacturing industries use Teflon for seals, gaskets, and machinery components that come into direct contact with reactive substances, ensuring product purity and preventing equipment degradation.

Extreme Thermal Stability

Teflon components maintain their structural integrity and performance characteristics across a very wide temperature range, from cryogenic lows to highs of 260°C (500°F).

This property is vital in the aerospace and automotive industries, where parts are exposed to significant temperature fluctuations in engines, fuel systems, and hydraulic applications.

Exceptionally Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, giving it a unique "non-stick" quality. This is ideal for applications requiring smooth, repeatable movement with minimal wear.

It is frequently used for high-performance bearings, gears, and valve components in the medical, automotive, and aerospace sectors.

Superior Electrical Insulation

As an excellent electrical insulator with a high dielectric strength, Teflon is crucial for preventing electrical leakage and ensuring signal integrity.

The semiconductor and electronics industries depend on machined Teflon for insulators, connectors, and components used in the fabrication of microchips, where electrical purity is paramount.

Biocompatibility and Purity

Teflon is biocompatible, meaning it is non-toxic and does not produce an immune response when introduced to the human body.

This makes it a cornerstone of the medical industry, used for surgical instruments, catheters, and even permanent implants like heart valves and artificial ligaments.

Understanding the Trade-offs

While Teflon's benefits are significant, it is not a universally perfect material. An objective assessment requires understanding its limitations.

Relatively Low Mechanical Strength

Compared to engineering plastics like PEEK or metals, Teflon is a soft material. It is susceptible to "creep" under sustained load and is not suitable for high-stress structural applications.

Specialized Machining Requirements

The softness that makes Teflon easy to machine also presents challenges. It requires specialized tools, techniques, and handling to hold tight tolerances and prevent the material from deforming or creating burrs during the CNC machining process.

Higher Material Cost

Teflon is a premium performance polymer. Its cost is higher than that of more common plastics like nylon or Delrin (acetal), which must be factored into any project's budget.

Making the Right Choice for Your Goal

The decision to use Teflon should be based on a clear understanding of its strengths in the context of your primary engineering challenge.

- If your primary focus is fluid purity and corrosion resistance: Teflon's chemical inertness is its greatest asset, making it the clear choice for the chemical, food, and medical industries.

- If your primary focus is smooth movement and reduced wear: Teflon's exceptionally low coefficient of friction is the deciding factor for bearings, seals, and dynamic components.

- If your primary focus is electrical signal integrity: Teflon's high dielectric strength makes it an ideal and often necessary insulator for advanced electronics and semiconductors.

- If your primary focus is high structural strength: Be aware of Teflon's limitations and consider either filled grades of PTFE or alternative materials designed for high-load applications.

Ultimately, Teflon's value is defined by its ability to operate with unparalleled reliability where conventional materials would invariably fail.

Summary Table:

| Key Property | Primary Benefit | Critical Industries |

|---|---|---|

| Chemical Inertness | Resists nearly all corrosive substances | Chemical Processing, Food & Beverage, Medical |

| Thermal Stability | Performs from cryogenic to 260°C (500°F) | Aerospace, Automotive |

| Low Friction | Non-stick, reduces wear in moving parts | Medical, Automotive, Aerospace |

| Electrical Insulation | High dielectric strength, ensures signal purity | Semiconductor, Electronics |

| Biocompatibility | Non-toxic, safe for medical implants | Medical & Life Sciences |

Need a custom Teflon (PTFE) component that can withstand extreme conditions?

KINTEK specializes in precision machining of high-performance PTFE components like seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we deliver the reliability and purity your application demands.

We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet the tightest tolerances. Let us help you solve your most challenging material problems.

Contact our engineering team today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech