In short, PTFE gaskets are essential in systems with varying temperatures because of their exceptional thermal stability. They maintain a reliable, leak-proof seal across an extremely wide temperature range, from cryogenic lows to high-heat industrial processes, without deforming, degrading, or losing their core properties.

The true value of PTFE in fluctuating thermal conditions isn't just its high melting point, but the powerful combination of thermal stability, chemical inertness, and consistent sealing performance that ensures system integrity when other materials would fail.

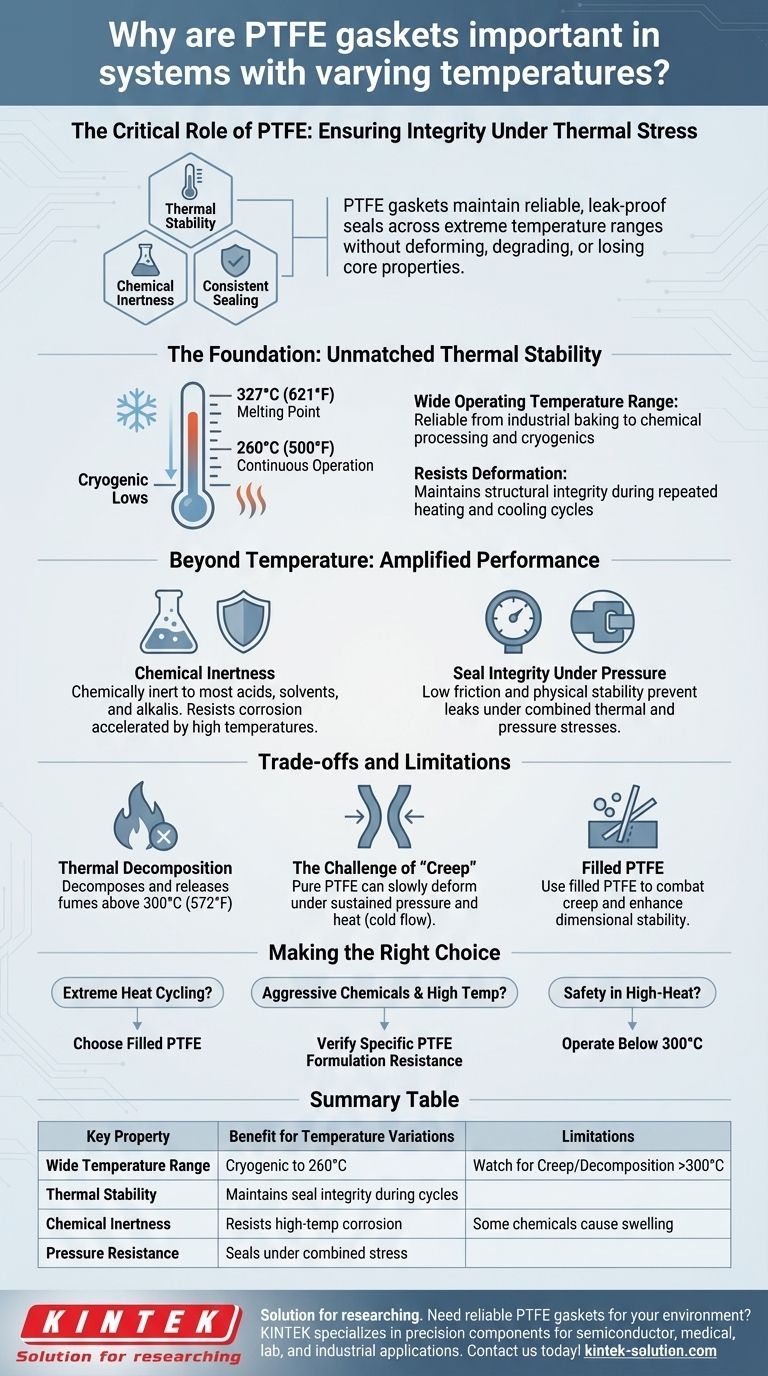

The Foundation of PTFE's Performance: Unmatched Thermal Stability

Polytetrafluoroethylene (PTFE) possesses unique material properties that make it uniquely suited for environments where temperature is not a constant.

A Wide Operating Temperature Range

PTFE has a very high melting point of 327°C (621°F) and can be used continuously at temperatures up to 260°C (500°F) without significant degradation. This makes it reliable for applications ranging from industrial baking to chemical processing.

This stability also extends to extremely low temperatures, making it a viable choice for cryogenic applications where other materials would become brittle and crack.

Resisting Deformation and Degradation

Unlike many materials that soften, deform, or lose their sealing ability when heated, PTFE maintains its structural integrity. This ensures the gasket continues to provide a tight seal even as the system heats up and cools down repeatedly.

Why Stability is More Than Just Temperature

PTFE's effectiveness in varying temperatures is amplified by its other core properties. Temperature fluctuations often occur in environments that are also chemically aggressive or under high pressure.

The Critical Role of Chemical Inertness

PTFE is one of the most chemically inert materials known. It does not react with the vast majority of acids, solvents, and alkalis.

This is crucial because higher temperatures can accelerate corrosion and chemical attacks. A PTFE gasket resists this breakdown, ensuring a longer service life and preventing contamination of the media it contains.

Maintaining Seal Integrity Under Pressure

PTFE's low friction coefficient and physical stability allow it to maintain a better seal, especially as temperatures and pressures rise. It effectively prevents leaks where less stable materials might fail, ensuring reliable performance in demanding energy and processing industries.

Understanding the Trade-offs and Limitations

While highly effective, PTFE is not without its operational boundaries. Understanding these is key to using it safely and effectively.

The Risk of Thermal Decomposition

When heated above 300°C (572°F), PTFE can begin to decompose and release fumes that can cause respiratory irritation. It is critical to ensure that operating conditions remain well below this threshold.

The Challenge of "Creep"

In its pure form, PTFE can be susceptible to "creep" or "cold flow," where the material slowly deforms under sustained pressure. This is especially true in high-temperature applications.

To counteract this, gaskets are often made with filled PTFE, which includes materials like glass or carbon. These fillers significantly improve the gasket's resistance to creep and enhance its dimensional stability under heat and load.

Matching the Gasket to the Media

While chemically inert to most substances, certain specific chemicals can cause PTFE to swell or become brittle. It is essential to consider the complete operating environment—temperature, pressure, and media—to select the correct grade of PTFE gasket.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's properties to the system's demands.

- If your primary focus is extreme heat cycling: Choose a filled PTFE gasket to combat creep and ensure the gasket maintains its shape and seal integrity over time.

- If your primary focus is handling aggressive chemicals at high temperatures: Verify the specific PTFE formulation's resistance to the media, as its properties can be affected by certain compounds.

- If your primary focus is safety in high-heat processes: Always operate well below the decomposition temperature of 300°C and ensure system designs account for this critical safety limit.

By understanding these properties and limitations, you can leverage PTFE's strengths to ensure uncompromising system integrity in demanding thermal environments.

Summary Table:

| Key Property | Benefit for Temperature Variations |

|---|---|

| Wide Temperature Range | Operates from cryogenic to 260°C (500°F) without degradation |

| Thermal Stability | Maintains seal integrity during repeated heating/cooling cycles |

| Chemical Inertness | Resists corrosion from acids/solvents, especially at high temperatures |

| Pressure Resistance | Maintains seal under combined thermal and pressure stresses |

| Limitations | Watch for creep (use filled PTFE) and thermal decomposition above 300°C |

Need a PTFE gasket that performs reliably in your specific temperature environment? At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for semiconductor, medical, laboratory, and industrial applications. Whether you require custom prototypes or high-volume orders, our expertise ensures your gaskets deliver leak-proof integrity under thermal stress. Contact us today to discuss your application requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials