At its core, Polytetrafluoroethylene (PTFE) is a material of last resort and first choice. It excels where conventional materials fail, making it indispensable across a wide range of demanding industries. PTFE seals and rings are critical components in sectors like aerospace, automotive, oil and gas, chemical processing, medical, and food production due to their unique ability to withstand extreme conditions.

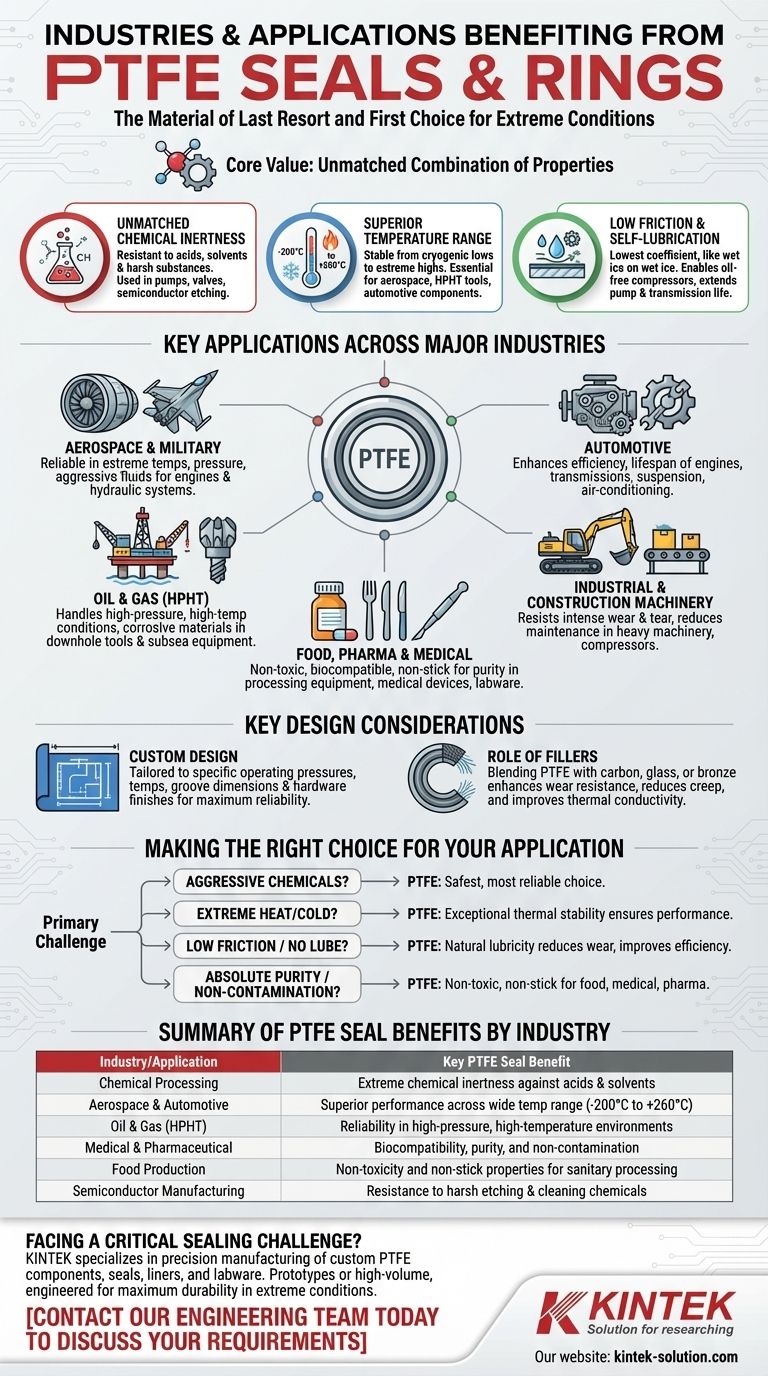

The widespread adoption of PTFE isn't about a single feature, but its rare combination of three key properties: extreme chemical inertness, a vast operating temperature range, and an inherently low coefficient of friction. This makes it a unique problem-solver for the most challenging sealing applications.

Why PTFE Is the Go-To for Extreme Environments

The value of PTFE is best understood by looking at its fundamental material properties. These characteristics directly address common points of failure in mechanical systems, from chemical corrosion to heat degradation and excessive wear.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, acids, and solvents. This makes it the default choice for equipment that handles aggressive or corrosive substances.

This property is critical in the chemical and petrochemical industries for pumps and valves, and in semiconductor manufacturing where harsh chemicals are used for etching and cleaning.

Superior Performance Across a Wide Temperature Range

PTFE seals maintain their integrity and performance in conditions ranging from cryogenic lows to extreme highs, a range that causes most other polymers to become brittle or melt.

This thermal stability is essential for aerospace applications like engines and hydraulic systems, as well as for automotive components and oil and gas equipment in high-pressure, high-temperature (HPHT) downhole tools.

Inherent Low Friction and Self-Lubrication

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This natural lubricity reduces wear and tear on moving parts and improves system efficiency.

This allows for the design of oil-free or low-lube compressors used in food processing, pharmaceutical, and dental applications where contamination is not an option. It also extends the life of components in automotive transmissions and industrial pumps.

Purity and Safety for Sensitive Applications

Because it is non-toxic, biocompatible, and has non-stick properties, PTFE is perfectly suited for environments where purity is paramount. It prevents residue buildup and does not react with the materials it contacts.

This is why it's heavily used in the food and pharmaceutical industries for processing equipment and in medical devices such as surgical tools, hematology analyzers, and autoclaves.

Key Applications Across Major Industries

Understanding the core properties of PTFE makes it clear why it has been adopted so broadly. Each industry leverages a specific combination of its benefits.

Aerospace and Military

In this sector, reliability is non-negotiable. PTFE seals are used in aircraft engines, hydraulic systems, pumps, and brakes where they must withstand extreme temperatures, high pressures, and aggressive fluids.

Automotive

PTFE's durability and low friction are vital for improving the efficiency and lifespan of automotive components. Common uses include seals for engines and transmissions, suspension components, and air-conditioning systems.

Oil and Gas

From subsea equipment to downhole drilling tools, the oil and gas industry relies on PTFE to handle HPHT conditions and corrosive materials, ensuring operational integrity in some of the world's harshest environments.

Industrial and Construction Machinery

Heavy machinery like excavators, loaders, conveyors, and industrial compressors require seals that can resist intense wear and tear. PTFE's durability and temperature resistance reduce maintenance frequency and costly downtime.

Key Design Considerations for PTFE Seals

While incredibly versatile, PTFE is not a universal plug-and-play solution. Maximum performance is achieved when the seal design is tailored to the specific application's demands.

The Importance of Custom Design

The effectiveness of a PTFE seal depends on a design that accounts for the precise operating pressures, temperatures, and media involved. Factors like groove dimensions and hardware finishes are critical for ensuring a reliable, long-lasting seal.

The Role of Fillers

Base PTFE can be blended with fillers like carbon, glass fiber, or bronze to enhance specific properties. Adding fillers can significantly increase wear resistance, reduce creep (the tendency to deform under load), and improve thermal conductivity for even more demanding applications.

Making the Right Choice for Your Application

Selecting the right seal material comes down to identifying the primary challenge you need to solve.

- If your primary focus is handling aggressive chemicals or solvents: PTFE's near-total chemical inertness makes it the safest and most reliable choice.

- If your application operates in extreme heat or cryogenic cold: PTFE's exceptional thermal stability ensures performance where other materials would fail.

- If your system requires low friction or cannot be lubricated: PTFE's natural lubricity is a critical advantage for reducing wear and improving efficiency.

- If your process demands absolute purity and non-contamination: PTFE's non-toxic and non-stick properties are essential for food, medical, and pharmaceutical uses.

By matching the unique strengths of PTFE to your specific operational challenge, you can engineer a more durable, efficient, and reliable system.

Summary Table:

| Industry/Application | Key PTFE Seal Benefit |

|---|---|

| Chemical Processing | Extreme chemical inertness against acids and solvents |

| Aerospace & Automotive | Superior performance across a wide temperature range (-200°C to +260°C) |

| Oil & Gas (HPHT) | Reliability in high-pressure, high-temperature environments |

| Medical & Pharmaceutical | Biocompatibility, purity, and non-contamination |

| Food Production | Non-toxicity and non-stick properties for sanitary processing |

| Semiconductor Manufacturing | Resistance to harsh etching and cleaning chemicals |

Facing a critical sealing challenge? KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your components are engineered for maximum durability and performance in extreme conditions.

Contact our engineering team today to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the two main methods for producing PTFE? Choose the Right Path for Your Application

- What benefits do PTFE expansion bellows offer in water treatment facilities? Enhance System Reliability & Reduce Costs

- What are the temperature resistance capabilities of PTFE with fillers? Select the Right High-Performance Material

- How do PTFE gaskets contribute to electrical insulation? Ensuring Reliability in Harsh Environments

- What are the benefits of PTFE packing? Superior Sealing for Harsh Chemicals and High Purity

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- How does PTFE's high-temperature tolerance benefit shaft seals? Ensure Reliability in Extreme Heat

- What are spring-energized PTFE seals and why are they used? Solve Demanding Sealing Challenges