At its core, the durability of PTFE plugs stems from the material’s unique molecular structure. Polytetrafluoroethylene (PTFE) is engineered to be exceptionally non-reactive and stable, giving it a powerful combination of chemical inertness, resistance to extreme temperatures, and resilience against physical and environmental degradation. These properties ensure the plugs maintain their structural integrity and sealing capability in demanding conditions where other materials would quickly fail.

The true durability of a PTFE plug is not just about its strength, but its profound ability to resist degradation. It excels by remaining unchanged when exposed to chemicals, UV light, moisture, and temperature fluctuations that compromise lesser materials.

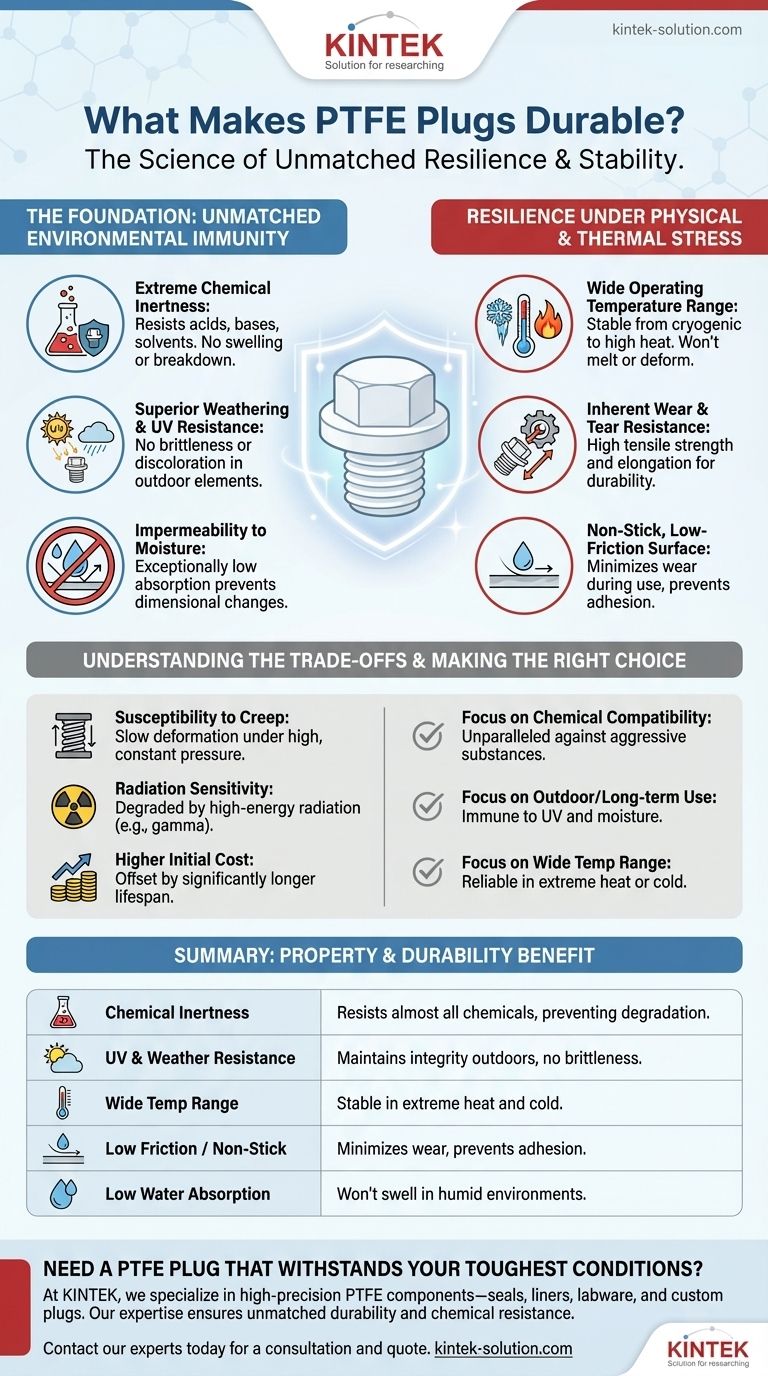

The Foundation: Unmatched Environmental Immunity

The first layer of PTFE's durability is its near-total immunity to chemical and environmental attack. This makes it a default choice for applications involving harsh substances or long-term exposure.

Extreme Chemical Inertness

PTFE is resistant to almost all common chemicals, acids, and solvents. This chemical stability means the plug will not swell, soften, or break down when in contact with aggressive fluids, ensuring a reliable seal and preventing contamination.

Superior Weathering and UV Resistance

Unlike many plastics that become brittle and discolor with sun exposure, PTFE is highly resistant to weathering, oxidation, and UV light. This allows PTFE plugs to be used in outdoor applications for years without degrading or losing their essential properties.

Impermeability to Moisture

The material has exceptionally low water absorption and permeability. PTFE plugs will not absorb moisture from the environment, which prevents them from swelling, changing dimensions, or losing their mechanical integrity over time.

Resilience Under Physical and Thermal Stress

Beyond its chemical resistance, PTFE is built to withstand significant physical and thermal challenges, which contributes directly to its long service life.

Wide Operating Temperature Range

PTFE maintains its performance across an extremely broad temperature range. With a high melting point and stability at low temperatures, it will not melt, deform, or become brittle in environments that cause other polymers to fail.

Inherent Wear and Tear Resistance

PTFE exhibits good tensile strength and high elongation (the ability to stretch without breaking). This combination means it can resist physical wear and tearing during installation, removal, and use, maintaining its shape and function.

Non-Stick, Low-Friction Surface

The famous non-stick surface of PTFE is a key durability feature. This low coefficient of friction minimizes wear during insertion or dynamic use and prevents other materials from adhering to the plug, which could otherwise cause damage upon removal.

Understanding the Trade-offs

No material is perfect. Acknowledging the trade-offs of PTFE is critical for making an informed decision and avoiding misapplication.

Susceptibility to Creep

While durable, PTFE is a relatively soft material. Under a constant, high-pressure load, it can be susceptible to "creep," a slow, permanent deformation over time. This is a critical consideration for high-pressure static sealing applications.

Radiation Sensitivity

While resistant to UV light, PTFE can be degraded by high-energy radiation, such as gamma or electron-beam radiation. This exposure can break down the molecular structure and compromise its physical properties.

Higher Initial Cost

The advanced properties and complex manufacturing process of PTFE often result in a higher upfront cost compared to conventional plastics or rubbers. However, this is frequently offset by its significantly longer lifespan and reduced need for replacement, making it cost-effective over the long term.

Making the Right Choice for Your Application

To determine if PTFE plugs are the correct solution, you must match their specific strengths to the primary challenges of your environment.

- If your primary focus is chemical compatibility: PTFE is an unparalleled choice for sealing against aggressive acids, bases, and organic solvents.

- If your primary focus is outdoor or long-term use: Its immunity to UV radiation and moisture ensures it will not degrade, crack, or become brittle over time.

- If your primary focus is a wide temperature range: PTFE's stability in both high heat and cryogenic conditions makes it exceptionally reliable where other materials would fail.

- If your primary focus is a high-pressure mechanical seal: Carefully evaluate the potential for creep and consider if a harder material or a filled-PTFE composite is more appropriate.

Ultimately, understanding these distinct properties empowers you to deploy PTFE plugs where their unique durability offers the greatest advantage.

Summary Table:

| Property | Benefit for Durability |

|---|---|

| Chemical Inertness | Resists almost all acids, bases, and solvents, preventing degradation. |

| UV & Weather Resistance | Maintains integrity outdoors without becoming brittle or discoloring. |

| Wide Temperature Range | Stable from cryogenic to high-heat environments without deforming. |

| Low Friction / Non-Stick | Minimizes wear during insertion/removal and prevents material adhesion. |

| Low Water Absorption | Won't swell or change dimensions in humid or wet environments. |

Need a PTFE Plug That Withstands Your Toughest Conditions?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, labware, and custom plugs—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components deliver the unmatched durability and chemical resistance detailed above.

We provide custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications. Let us help you solve your most challenging sealing problems.

Contact our experts today for a consultation to discuss your application needs and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments