At their core, the installation advantages of PTFE lined butterfly valves stem directly from their simple, compact, and lightweight design. This allows them to be installed easily in tight spaces with minimal equipment and offers significant flexibility in the layout of piping systems.

The primary advantage isn't just the ease of the physical installation itself, but how that simplicity translates into lower project costs, faster commissioning, and greater freedom for system designers.

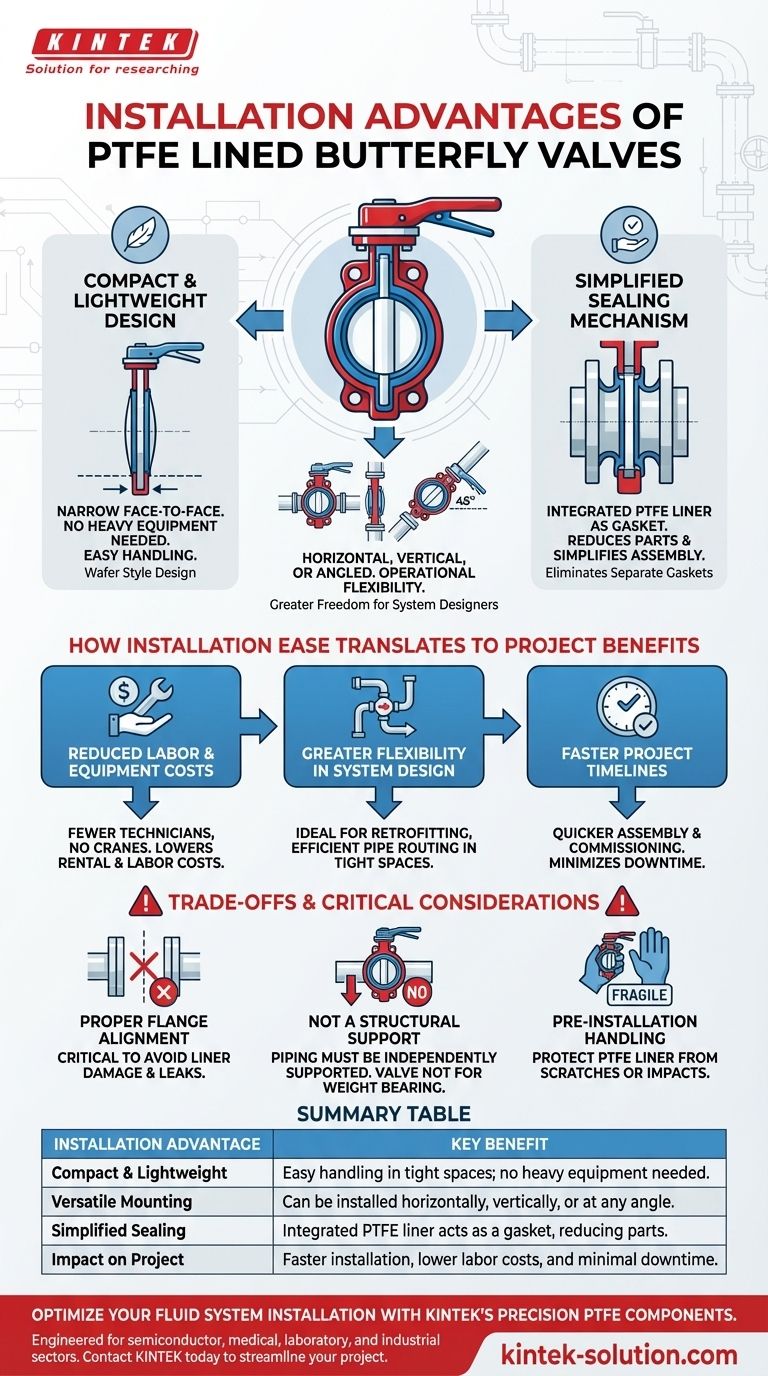

The Core Installation Advantages Explained

The physical characteristics of PTFE lined butterfly valves directly contribute to a simplified installation process compared to heavier, more complex valve types like gate or globe valves.

Compact and Lightweight Design

PTFE lined butterfly valves have a very narrow face-to-face dimension, meaning they take up minimal space in the pipeline. This is often referred to as a "wafer" style design.

Their construction is inherently lighter than other valve types designed for the same pipe diameter, making them easier for technicians to handle and position without requiring heavy lifting equipment.

Versatile Mounting Orientation

A key benefit is their operational flexibility regardless of position. These valves can be installed horizontally, vertically, or at any angle without compromising their function.

This versatility gives engineers and designers significant freedom when laying out complex piping runs, as they are not constrained by valve orientation requirements.

Simplified Sealing Mechanism

The valve is designed to be clamped between two pipe flanges. The PTFE liner often extends over the face of the valve body, creating its own gasket.

This integrated sealing surface can eliminate the need for separate gaskets, reducing the number of components required and simplifying the assembly process.

How Installation Ease Translates to Project Benefits

The practical advantages of a straightforward installation process have a direct and positive impact on project timelines, budgets, and overall system design.

Reduced Labor and Equipment Costs

The lightweight nature of these valves means fewer technicians are needed for installation, and the need for cranes or heavy machinery is often eliminated, especially in smaller pipe sizes. This directly lowers labor and equipment rental costs.

Greater Flexibility in System Design

Because the valves are compact and can be mounted in any orientation, they are ideal for retrofitting existing systems or for new projects where space is at a premium. This allows for more efficient and less complex pipe routing.

Faster Project Timelines

A simpler, quicker installation process means systems can be assembled and commissioned faster. During maintenance cycles, this ease of replacement minimizes costly system downtime.

Understanding the Trade-offs and Considerations

While installation is straightforward, achieving a reliable, leak-free seal depends on proper procedure and an understanding of the valve's limitations.

Critical Need for Proper Flange Alignment

The most crucial factor for a successful installation is ensuring the pipe flanges are perfectly parallel and aligned. Misalignment can cause the liner to be pinched or unevenly compressed, leading to premature failure and leaks.

Not a Structural Support

The valve's lightweight body is not designed to bear the weight of the piping. The piping system must be independently and adequately supported on both sides of the valve to prevent stress on the valve body and connections.

Pre-Installation Handling

The PTFE liner, especially the sealing faces, can be damaged by scratches or impacts. Careful handling is required before and during installation to protect the integrity of these critical surfaces.

Making the Right Choice for Your System

Selecting a valve based on its installation advantages is a valid engineering decision, especially when certain project constraints are a priority.

- If your primary focus is retrofitting a system with limited space: The compact, wafer-style design of a PTFE lined butterfly valve is its most significant advantage.

- If your primary focus is minimizing installation time and labor costs: The valve's lightweight construction and simple handling requirements will deliver the most value.

- If your primary focus is designing a complex new piping system: The ability to mount the valve in any orientation provides unmatched flexibility and simplifies the overall design.

By understanding how these practical installation benefits align with your project goals, you can design a more efficient, cost-effective, and reliable fluid control system.

Summary Table:

| Installation Advantage | Key Benefit |

|---|---|

| Compact & Lightweight | Easy handling in tight spaces; no heavy equipment needed. |

| Versatile Mounting | Can be installed horizontally, vertically, or at any angle. |

| Simplified Sealing | Integrated PTFE liner acts as a gasket, reducing parts. |

| Impact on Project | Faster installation, lower labor costs, and minimal downtime. |

Optimize your fluid system installation with KINTEK's precision PTFE components.

Our PTFE lined butterfly valves are engineered for the semiconductor, medical, laboratory, and industrial sectors, where ease of installation, reliability, and cost-effectiveness are critical. Whether you need standard parts or custom-fabricated prototypes and high-volume orders, our focus on precision ensures a perfect fit and long-lasting performance.

Contact KINTEK today to discuss how our valves can streamline your project and reduce total cost of ownership.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the benefits of annealing PTFE after machining? Ensure Dimensional Stability & Prevent Failure

- What are the main components constructed from PTFE in these valves? Ensure Ultimate Purity and Chemical Resistance

- What types of cutting tools are recommended for machining PTFE? Achieve Clean Cuts and Tight Tolerances

- What are the key roles of gland packing in industrial applications? Achieve Robust, Controllable Sealing

- What are the characteristics of Polytetrafluoroethylene (PTFE) with Carbon-Graphite Fill for aqueous fluid media? Enhance Sealing Performance

- What makes ePTFE suitable for filtration applications? Unlock Superior Performance for Demanding Environments

- When should RPTFE not be used? Avoid Component Failure with HF and Caustics

- Why do expanded PTFE gaskets have excellent creep resistance? Unlock Long-Term Sealing Reliability