The primary role of gland packing is to create a robust, dynamic seal around a moving shaft or stem in industrial equipment like pumps and valves. It functions by being compressed within a housing (the stuffing box), forcing it against the moving components to control or prevent fluid leakage under demanding conditions of pressure, temperature, and chemical exposure.

Gland packing's core purpose is not just to seal, but to provide a controlled and adjustable seal. Its enduring value lies in its simplicity, versatility, and its function as a sacrificial element that protects more expensive equipment components.

How Gland Packing Fulfills Its Role

Gland packing is a deceptively simple technology, but its effectiveness comes from a precise mechanical principle. It is a workhorse in industries where reliability and serviceability are paramount.

The Principle of Controlled Compression

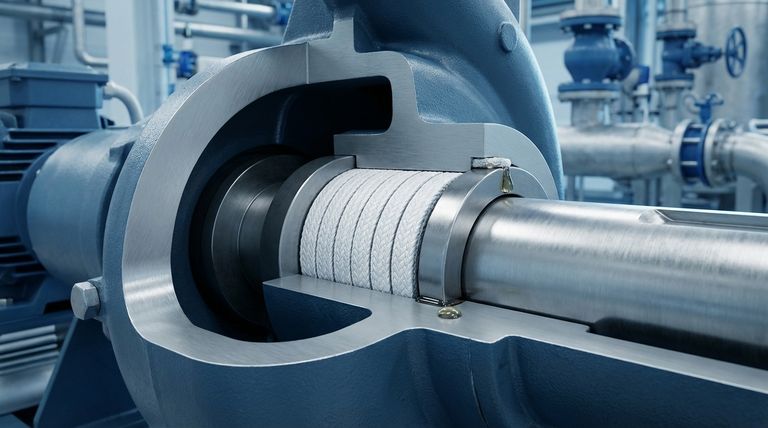

Gland packing is not a single component but a system. Braided rings of material are inserted into the space between the rotating shaft and the pump housing, known as the stuffing box.

A component called the gland follower is then tightened. This applies axial pressure to the rings, causing them to expand radially and press firmly against both the shaft and the stuffing box wall, creating a seal.

Creating a Dynamic, Sacrificial Seal

Unlike a static O-ring or gasket, gland packing is designed to seal against a moving surface. This is its most critical function.

The packing material itself is chosen to be a sacrificial wear surface. It is designed to wear down over time, protecting the far more expensive and difficult-to-replace pump shaft or valve stem from damage.

The Key Functions in Industrial Applications

Beyond simply stopping a leak, gland packing performs several vital jobs that ensure the safe and efficient operation of machinery.

Preventing Product Leakage and Contamination

The most obvious role is to keep the pumped fluid contained. This is critical for preventing the loss of valuable products, avoiding environmental contamination, and ensuring a safe work area by containing hazardous materials.

Protecting Equipment Bearings

By effectively sealing the "wet end" of a pump, gland packing prevents the process fluid from migrating along the shaft. This protects the motor bearings from contamination and corrosion, which is a common cause of premature equipment failure.

Accommodating Shaft and Stem Movement

Gland packing is specifically designed for dynamic applications. It maintains a consistent seal on a rotating pump shaft or a reciprocating valve stem, accommodating minor imperfections and movements without catastrophic failure.

Tolerating Demanding Operating Conditions

Modern packing materials are highly engineered. They are selected to provide chemical resistance, withstand extreme temperatures, and handle high pressures, making the method suitable for a vast range of industrial processes.

Understanding the Inherent Trade-offs

No sealing solution is perfect for every scenario. The effectiveness of gland packing is tied to understanding its operational characteristics and limitations.

Controlled Leakage vs. Zero Leakage

In many pump applications, gland packing is intentionally set to allow a very small, controlled leakage rate (e.g., a few drops per minute). This tiny flow of fluid acts as a lubricant and coolant for the packing and shaft, preventing overheating and premature wear. This is a fundamental difference from mechanical seals, which are designed for zero leakage.

Requirement for Regular Maintenance

Gland packing is not a "fit-and-forget" solution. As the material wears, the gland follower must be periodically tightened to maintain the correct compression and sealing pressure. Over-tightening can rapidly destroy both the packing and the shaft.

Potential for Shaft Wear

While packing is meant to be sacrificial, improper installation, incorrect material choice, or poor maintenance can lead to accelerated wear on the shaft itself. This negates one of its primary benefits and can lead to costly repairs.

Applying This to Your Sealing Strategy

The choice and application of gland packing depend entirely on the specific demands of your equipment and process.

- If your primary focus is containing aggressive chemicals: Prioritize packing materials like PTFE or graphite with certified chemical compatibility for your specific fluid.

- If your primary focus is high-speed rotating equipment: Select a packing with excellent heat dissipation properties and a low coefficient of friction to prevent overheating.

- If your primary focus is high-pressure valves: Choose a dense, resilient packing, often reinforced with carbon or metallic fibers, designed to resist extrusion under high pressure.

Gland packing remains a vital industrial tool because it provides a reliable, serviceable, and cost-effective sealing solution across an immense range of applications.

Summary Table:

| Key Role | Primary Function | Benefit |

|---|---|---|

| Dynamic Sealing | Creates a seal on rotating/reciprocating shafts | Prevents product loss & contamination |

| Equipment Protection | Seals the wet end of pumps | Protects bearings from corrosion & failure |

| Sacrificial Wear Surface | Designed to wear down over time | Protects expensive shafts and stems from damage |

| Tolerance for Conditions | Withstands high pressure, temperature, and chemicals | Ensures reliability in demanding processes |

Need a reliable sealing solution for your demanding application?

Gland packing is a workhorse, but its performance depends on precision manufacturing and the right material choice. At KINTEK, we specialize in high-performance PTFE components, including custom gland packing solutions. Our expertise in custom fabrication for the semiconductor, medical, laboratory, and industrial sectors ensures you get a seal that offers superior chemical resistance, low friction, and long-lasting performance—from prototypes to high-volume orders.

Let us help you protect your equipment and optimize your process. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency