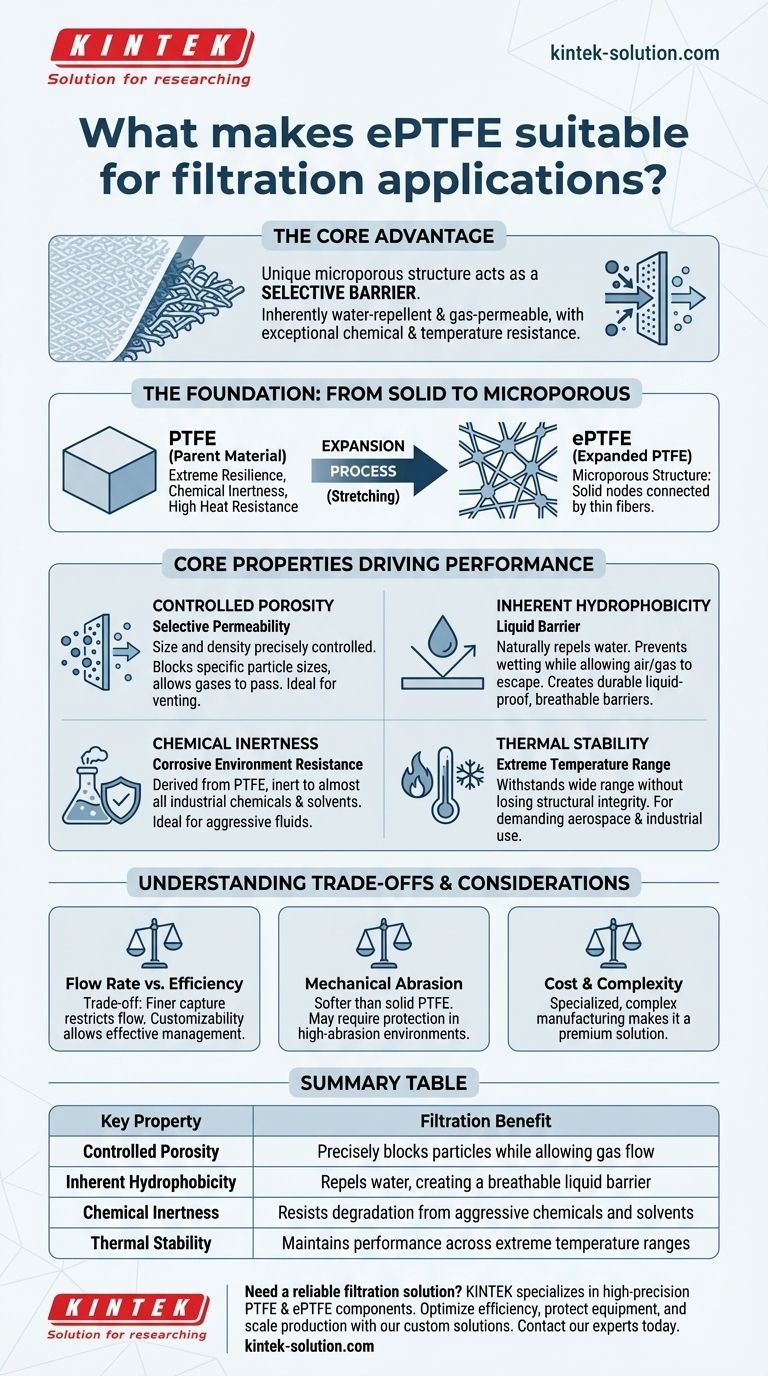

To put it directly, ePTFE is highly effective for filtration because its unique microporous structure acts as a selective barrier. This structure, created by expanding PTFE, is inherently water-repellent (hydrophobic) and permeable to gases, all while retaining the exceptional chemical and temperature resistance of its parent material.

The core advantage of ePTFE in filtration is not just one property, but the combination of its physical structure and chemical stability. It creates a filter media that can precisely control what passes through while remaining undamaged by harsh operating conditions.

The Foundation: From Solid Block to Microporous Filter

To understand ePTFE's capabilities, it’s essential to recognize how it's made. It begins with PTFE (Polytetrafluoroethylene), a material already known for its extreme resilience.

The Parent Material: PTFE's Inherent Strengths

Polytetrafluoroethylene, or PTFE, is the starting point. It provides a foundation of exceptional properties, including high heat resistance, tolerance for extremely low temperatures, and near-universal chemical inertness.

The "Expansion" Process: Creating a Fibrous Structure

ePTFE, or expanded Polytetrafluoroethylene, is created through a process that stretches PTFE under specific conditions. This transforms the solid material into a microporous structure composed of solid nodes connected by a web of thin fibers.

This multi-directional fibrous structure is the key to its filtration performance. The spaces between these fibers form microscopic pores.

Core Properties Driving Filtration Performance

The unique structure created during the expansion process gives ePTFE four critical properties that make it a superior filtration medium.

Controlled Porosity for Selective Permeability

The size and density of the pores can be precisely controlled during manufacturing. This allows ePTFE to be engineered to block particles of a specific size while allowing gases or smaller molecules to pass through freely.

This enables applications like vents that allow air to pass for pressure equalization but block water droplets and contaminants.

Inherent Hydrophobicity for Liquid Barriers

ePTFE is naturally hydrophobic, meaning it repels water. This property is crucial for applications where moisture must be kept out while allowing air or other gases to escape.

The material's surface tension prevents water from wetting the surface and passing through the pores, creating a durable liquid-proof yet breathable barrier.

Chemical Inertness for Corrosive Environments

Because it is derived from PTFE, ePTFE is chemically inert to almost all industrial chemicals and solvents. This makes it ideal for filtering aggressive fluids or for use in corrosive environments where other filter materials would degrade.

Thermal Stability for Extreme Temperatures

ePTFE can withstand an extremely wide range of temperatures without losing its structural integrity. This allows it to be used in demanding aerospace and industrial applications, from high-temperature sensor covers to seals in aircraft.

Understanding the Trade-offs and Considerations

While ePTFE is a high-performance material, it's important to understand its practical limitations to ensure it's the right choice for an application.

Flow Rate vs. Filtration Efficiency

There is a fundamental trade-off between how finely a filter can capture particles and how quickly a fluid or gas can pass through it. A smaller, denser pore structure will capture smaller particles but will also restrict flow.

The high customizability of ePTFE allows this trade-off to be managed effectively, but it requires careful specification.

Mechanical Abrasion Resistance

The expansion process that creates the valuable porous structure also makes the material softer and less resistant to high-abrasion environments compared to solid PTFE. In applications with significant mechanical wear, the filter membrane may need to be protected.

Cost and Manufacturing Complexity

ePTFE is a specialized material that requires a complex manufacturing process. As a result, it is typically a more premium solution compared to conventional filter media like paper or cloth.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the operational demands of your system.

- If your primary focus is protecting electronics from water ingress: ePTFE's hydrophobic and microporous nature creates an ideal venting membrane that equalizes pressure while blocking moisture.

- If your primary focus is filtering aggressive chemicals or high-temperature fluids: Its foundation in PTFE provides the necessary chemical inertness and thermal stability for long-term reliability.

- If your primary focus is achieving a specific flow rate and particle capture: The customizable density and pore structure of ePTFE allow you to precisely tune the filter media to your performance requirements.

Ultimately, ePTFE's unique structural properties provide a highly adaptable and durable solution for the most demanding filtration challenges.

Summary Table:

| Key Property | Filtration Benefit |

|---|---|

| Controlled Porosity | Precisely blocks particles while allowing gas flow |

| Inherent Hydrophobicity | Repels water, creating a breathable liquid barrier |

| Chemical Inertness | Resists degradation from aggressive chemicals and solvents |

| Thermal Stability | Maintains performance across extreme temperature ranges |

Need a reliable filtration solution for demanding applications?

At KINTEK, we specialize in manufacturing high-precision PTFE and ePTFE components—including custom filter membranes, seals, liners, and labware—for semiconductor, medical, laboratory, and industrial applications. Our expertise in custom fabrication ensures you get the exact pore structure, chemical resistance, and thermal stability your filtration system requires.

We can help you:

- Optimize filtration efficiency with precisely engineered ePTFE membranes

- Protect sensitive equipment from moisture, chemicals, and particulate contamination

- Scale from prototypes to high-volume production with consistent quality

Contact our filtration experts today to discuss your specific requirements and discover how our custom PTFE solutions can enhance your system's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does the non-stick surface of PTFE benefit seals? Unlock Self-Cleaning Performance and Reliability

- What are PTFE piston seals commonly known as? The Critical Role of Teflon™ Seals in High-Performance Applications

- What are the three primary types of PTFE available for gaskets and seals? Choose the Right Material for Your Application

- What are the advantages of PTFE piston rings and guide rings for dry-running applications? Boost Efficiency and Purity

- What role does PTFE play in vibration dampening in piping systems? | Reduce Stress & Wear

- How do PTFE slide bearings compare to traditional expansion plates? Superior Performance & Lower Lifetime Cost

- What are the primary applications of PTFE guide strips? Enhance Cylinder Performance and Longevity

- What are common applications of low-friction PTFE? Solve Friction & Corrosion Challenges