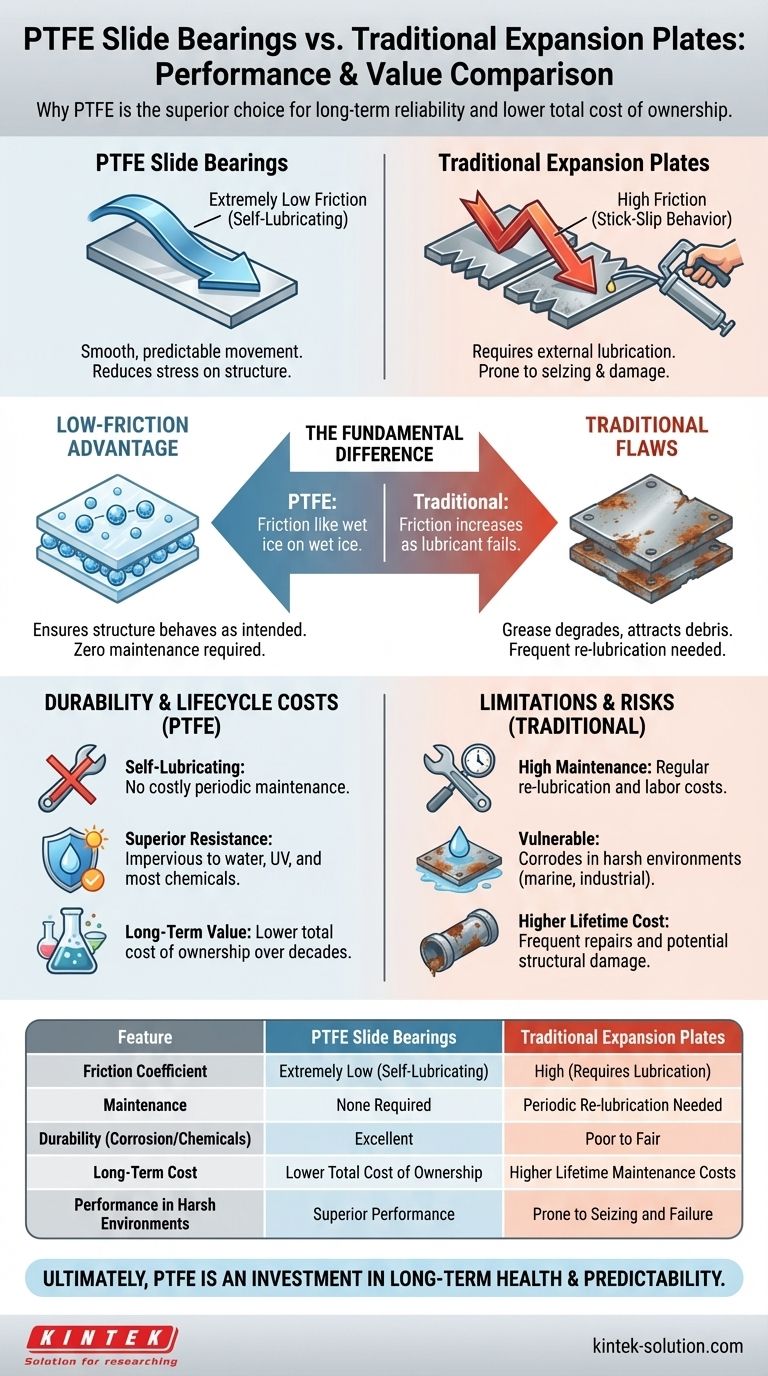

In a direct comparison, PTFE slide bearings significantly outperform traditional expansion plates by offering substantially lower friction, eliminating the need for maintenance, and providing superior durability in harsh environmental conditions. They are engineered for consistent, reliable performance where older technologies often fail over time.

The core difference isn't just about better materials; it's a fundamental shift from a high-maintenance, friction-prone system to a self-lubricating, highly resilient solution. Choosing PTFE is a decision for long-term reliability and a lower total cost of ownership.

The Fundamental Difference: Friction and Movement

The primary purpose of an expansion bearing is to accommodate movement—caused by thermal changes, load deflection, or seismic activity—while transferring vertical loads. How each technology handles this movement is the key differentiator.

The Low-Friction Advantage of PTFE

Polytetrafluoroethylene (PTFE) has one of the lowest coefficients of friction of any solid material, comparable to wet ice on wet ice.

This extremely low friction ensures that movement occurs smoothly and predictably, without building up damaging stress in the supporting structure. It allows the structure to behave exactly as the design intended.

The Problem with Traditional Plates

Traditional expansion plates, often consisting of two metal plates (like steel or bronze) sliding against each other, rely on external lubrication like grease.

This system is inherently flawed. The lubricant degrades over time, attracts dust and debris, and can be washed away, causing friction to increase dramatically. This leads to a "stick-slip" behavior, where stress builds up until it overcomes the friction, resulting in a sudden, jarring movement that can damage the structure.

Beyond Mechanics: Durability and Lifecycle Costs

An effective bearing must perform reliably for decades. This is where the material science of PTFE creates a significant advantage in total cost of ownership.

Self-Lubrication: The End of Maintenance

PTFE is inherently self-lubricating. Its low-friction properties are an integral part of the material itself and do not degrade.

This completely eliminates the costly and often difficult requirement for periodic re-lubrication. For bearings in inaccessible locations, such as deep within a bridge or a large building, this is a critical advantage.

Superior Resistance to Harsh Environments

Traditional metal plates are vulnerable to corrosion, especially in marine or industrial settings. Rust and pitting increase friction and can eventually cause the bearing to seize completely.

PTFE, on the other hand, is impervious to water and resistant to UV degradation. It maintains its performance characteristics across a very wide range of temperatures, from cryogenic lows to extreme highs, without becoming brittle or soft.

Unmatched Chemical Inertness

PTFE is one of the most chemically inert substances known. It is unaffected by nearly all industrial chemicals, solvents, and acids.

This makes PTFE slide bearings the default choice for chemical processing plants, coastal structures, and any environment where chemical exposure would quickly destroy a traditional metal bearing.

Understanding the Trade-offs

While PTFE offers clear advantages, a full technical assessment requires acknowledging its specific design considerations.

Potential for Creep Under Load

Like many polymers, PTFE can exhibit "creep," a slow deformation under sustained, heavy loads.

Modern slide bearings manage this by using filled or woven PTFE and by confining the PTFE element within a steel backing plate. This ensures that the material maintains its shape and performance under specified design loads.

Initial Cost vs. Total Cost of Ownership

The upfront material and fabrication cost of a PTFE slide bearing may be higher than a simple metal expansion plate.

However, when you factor in the elimination of all future maintenance costs (labor, equipment, lubricants) and the reduced risk of structural damage from a seized bearing, the total cost of ownership for PTFE is almost always significantly lower.

The Critical Role of Installation

The ultra-low friction of PTFE bearings is dependent on clean, flat mating surfaces. Proper installation, alignment, and surface preparation are critical to achieving design performance.

This is less a weakness and more a requirement for precision. Reputable manufacturers provide clear installation guidelines to ensure long-term success.

Making the Right Choice for Your Application

Selecting the correct bearing technology depends on prioritizing the long-term goals of your project.

- If your primary focus is minimizing long-term maintenance and operational costs: Choose PTFE slide bearings for their "install and forget" reliability.

- If your primary focus is predictable performance in a corrosive or extreme environment: The chemical and thermal stability of PTFE makes it the only viable choice.

- If your primary focus is the absolute lowest initial cost for a non-critical application: A traditional plate might be considered, but you must budget for its inevitable maintenance lifecycle and accept the higher risk of failure.

Ultimately, adopting PTFE slide bearings is an investment in your structure's long-term health and predictability.

Summary Table:

| Feature | PTFE Slide Bearings | Traditional Expansion Plates |

|---|---|---|

| Friction Coefficient | Extremely Low (Self-Lubricating) | High (Requires External Lubrication) |

| Maintenance | None Required | Periodic Re-lubrication Needed |

| Durability (Corrosion/Chemicals) | Excellent | Poor to Fair |

| Long-Term Cost | Lower Total Cost of Ownership | Higher Lifetime Maintenance Costs |

| Performance in Harsh Environments | Superior Performance | Prone to Seizing and Failure |

Invest in the long-term reliability of your structure with precision-engineered PTFE components from KINTEK.

For over 40 years, KINTEK has been a trusted manufacturer of high-performance PTFE seals, liners, slide bearings, and custom labware. We serve demanding industries—including semiconductor, medical, and industrial processing—where failure is not an option.

Our expertise in custom fabrication ensures you get a solution tailored to your exact specifications, from prototypes to high-volume production, all while prioritizing the precision and durability your application requires.

Ready to eliminate maintenance and ensure predictable performance? Contact our engineering team today to discuss your project needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability