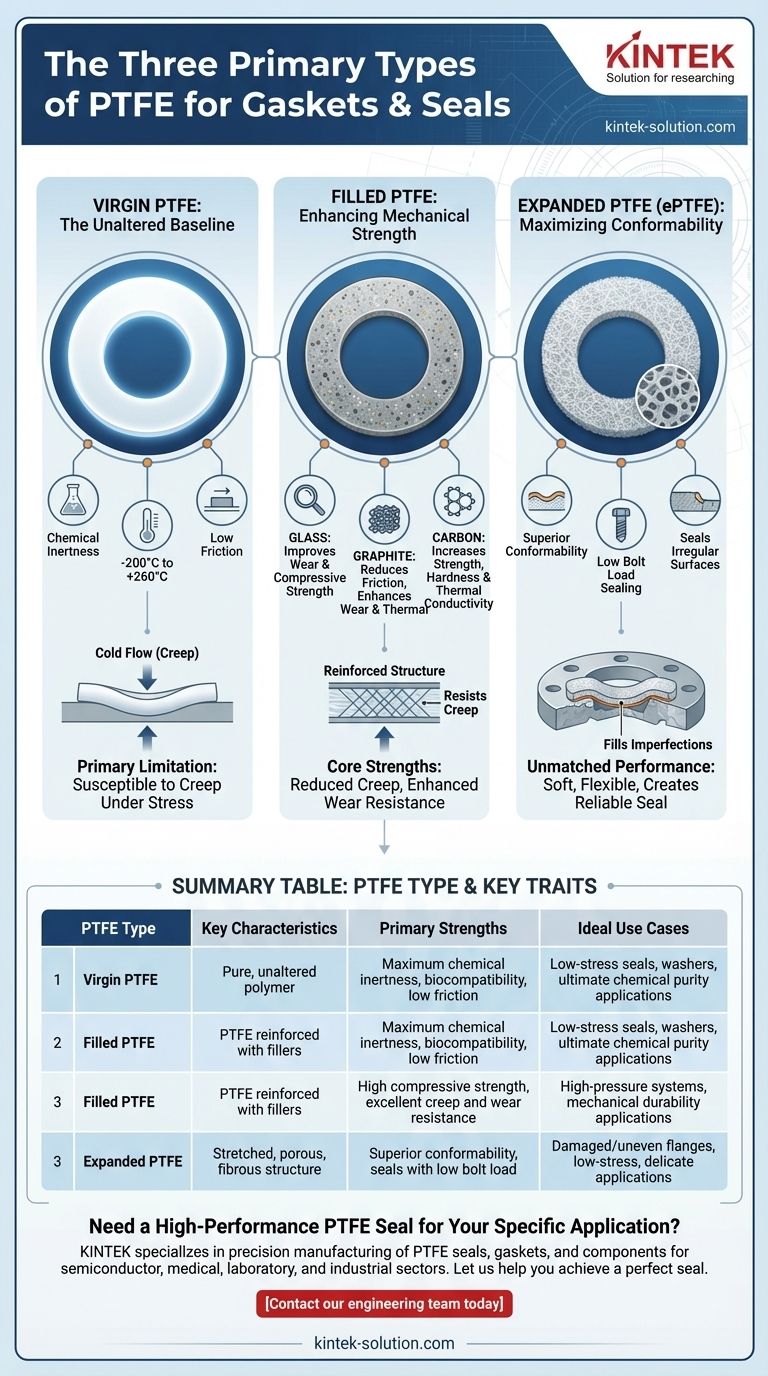

For gaskets and seals, the three primary types of Polytetrafluoroethylene (PTFE) are Virgin PTFE, Filled PTFE, and Expanded PTFE. Each type starts with the same base material but is engineered to solve different mechanical challenges, from improving strength to sealing irregular surfaces.

The choice between PTFE types is not about finding the "best" material, but about matching the specific mechanical demands of your application. While all three share PTFE's exceptional chemical and thermal resistance, their structural differences determine their suitability for handling pressure, creep, and surface imperfections.

Understanding the Foundation: Virgin PTFE

The Unaltered Baseline

Virgin PTFE is the pure, unaltered form of the polymer. It is created directly from PTFE resin without any added filler materials.

This purity makes it the most chemically inert and biocompatible of the three types, establishing the baseline properties for which PTFE is known.

Core Strengths

Virgin PTFE offers an outstanding combination of resistances. It is virtually indestructible against harsh chemicals, stable across extreme temperatures (-200°C to +260°C), and has an extremely low coefficient of friction.

The Primary Limitation: Cold Flow (Creep)

The most significant drawback of Virgin PTFE is its tendency to creep, or "cold flow," under mechanical stress. When compressed, the material can slowly deform and lose its sealing force over time, especially at higher temperatures.

Enhancing Mechanical Strength: Filled PTFE

How Fillers Change the Game

Filled PTFE is a composite material created by adding specific filler agents to the base PTFE resin. The goal is to improve the mechanical properties that Virgin PTFE lacks.

These fillers act as a reinforcing matrix within the PTFE, significantly reducing its tendency to creep under load and enhancing its wear resistance.

Common Fillers and Their Benefits

The properties of Filled PTFE are determined by the type and percentage of filler used. Common fillers include:

- Glass: Improves wear resistance and compressive strength.

- Graphite: Reduces friction, enhances wear properties, and improves thermal conductivity.

- Carbon: Increases compressive strength and hardness while providing good thermal conductivity.

Maximizing Conformability: Expanded PTFE (ePTFE)

A Unique Molecular Structure

Expanded PTFE (ePTFE) is created through a special process that physically stretches and expands the material. This rearranges the molecular structure into a strong, yet highly porous and soft, multi-directional fibrous material.

Unmatched Sealing Performance

The primary advantage of ePTFE is its exceptional compressibility and conformability. It is soft and flexible, allowing it to create a tight seal with very little compressive force (bolt load).

This makes it ideal for sealing delicate, damaged, or uneven flange surfaces where a rigid gasket would fail. It effectively fills in imperfections to create a reliable, long-lasting seal.

Understanding the Trade-offs

Virgin PTFE: Purity vs. Performance

While offering the highest chemical purity, Virgin PTFE's susceptibility to creep makes it unsuitable for high-pressure applications or those involving significant temperature cycling. It is best used for washers or in low-stress sealing environments.

Filled PTFE: Strength vs. Chemical Compatibility

Adding fillers dramatically improves mechanical strength and creep resistance. However, the filler material itself may not share the same universal chemical resistance as pure PTFE, which must be considered when selecting a gasket for aggressive media.

Expanded PTFE: Conformability vs. Rigidity

ePTFE is the ultimate solution for imperfect flanges and low-stress sealing. While it resists creep far better than Virgin PTFE, it may not be the ideal choice for extremely high-pressure systems that require the rigidity and high compressive strength of a heavily filled PTFE gasket.

How to Select the Right PTFE Gasket

The correct choice depends entirely on your application's specific mechanical and chemical demands.

- If your primary focus is chemical purity in low-stress applications: Virgin PTFE provides the essential properties without compromise.

- If your primary focus is resisting high pressure, wear, and creep: Filled PTFE offers the necessary mechanical strength and dimensional stability.

- If your primary focus is sealing irregular, damaged, or low-pressure flanges: Expanded PTFE delivers a superior, conformable seal with minimal bolt load.

Choosing the right PTFE variant ensures you leverage its core chemical strengths while perfectly matching its mechanical properties to the task at hand.

Summary Table:

| PTFE Type | Key Characteristics | Primary Strengths | Ideal Use Cases |

|---|---|---|---|

| Virgin PTFE | Pure, unaltered polymer | Maximum chemical inertness, biocompatibility, low friction | Low-stress seals, washers, applications requiring ultimate chemical purity |

| Filled PTFE | PTFE reinforced with fillers (glass, carbon, graphite) | High compressive strength, excellent creep and wear resistance | High-pressure systems, applications needing mechanical durability |

| Expanded PTFE (ePTFE) | Stretched, porous, fibrous structure | Superior conformability, seals with low bolt load, seals irregular surfaces | Damaged or uneven flanges, low-stress sealing, delicate applications |

Need a High-Performance PTFE Seal for Your Specific Application?

Choosing the right PTFE material is critical for the reliability and longevity of your components. At KINTEK, we specialize in the precision manufacturing of PTFE seals, gaskets, and custom components for the semiconductor, medical, laboratory, and industrial sectors.

We don't just supply parts; we provide solutions. Our experts will help you navigate the trade-offs between Virgin, Filled, and Expanded PTFE to select or fabricate the perfect seal for your unique requirements, whether you need a prototype or a high-volume order.

Let us help you achieve a perfect seal. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability