In piping systems, PTFE serves as a critical vibration dampener and stress reducer. It achieves this primarily by acting as a liner or pad that absorbs shock and cushions the impact between pipes and their support structures. Key components like PTFE expansion bellows are also installed directly into piping to absorb larger-scale vibrations and accommodate thermal movement.

The core function of PTFE in piping extends beyond simple vibration dampening. It addresses a trio of interconnected problems—vibration, friction, and thermal expansion—by providing a low-friction, absorbent barrier that protects the entire system from mechanical stress and premature wear.

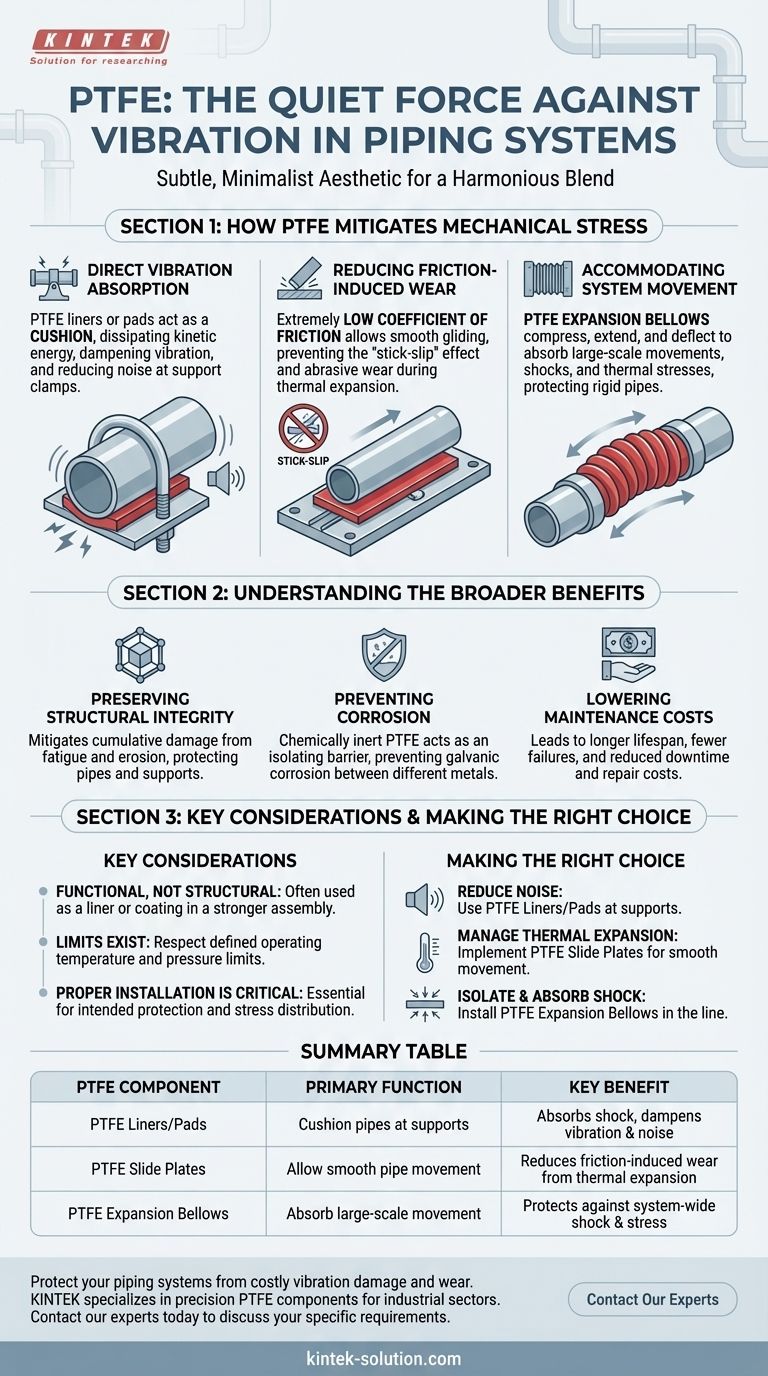

How PTFE Mitigates Mechanical Stress

PTFE's effectiveness comes from a unique combination of physical properties. These properties are leveraged in different components to solve distinct but related problems within a piping system.

Direct Vibration Absorption

Vibrations from pumps, fluid turbulence, or external sources cause pipes to move and chatter against their supports. When a PTFE liner or pad is placed between the pipe and the support clamp, it acts as a cushion. This soft, absorbent layer dissipates the kinetic energy of the impact, dampening the vibration and reducing associated noise.

Reducing Friction-Induced Wear

Pipes don't just vibrate; they also expand and contract with temperature changes. PTFE has an extremely low coefficient of friction, allowing pipes to glide smoothly across support structures. This prevents the "stick-slip" effect, where friction causes the pipe to catch and release, inducing stress and abrasive wear.

Accommodating System Movement

For larger-scale movements and system-wide vibrations, PTFE expansion bellows are integrated into the pipeline. These flexible, accordion-like components are designed to compress, extend, and deflect, absorbing mechanical shocks and thermal stresses that would otherwise fatigue and damage rigid pipe sections and equipment nozzles.

Understanding the Broader Benefits

By addressing the root causes of mechanical stress, PTFE delivers benefits that enhance the entire system's performance and longevity.

Preserving Structural Integrity

Constant vibration and friction lead to metal fatigue, surface erosion, and weakened connections. By mitigating these forces at every contact point, PTFE prevents cumulative damage, preserving the structural integrity of both the pipes and their supports over the long term.

Preventing Corrosion

PTFE is chemically inert and acts as an isolating barrier. By preventing direct metal-on-metal contact between a pipe and its support structure (which may be made of a different metal), it helps reduce the risk of galvanic corrosion.

Lowering Maintenance Costs

The direct result of reduced wear, vibration damage, and corrosion is a more reliable system. This translates to a longer operational lifespan, fewer unexpected failures, and a significant reduction in costly repairs and maintenance downtime.

Key Considerations and Trade-offs

While highly effective, it is crucial to understand the context in which PTFE is used. Its value is in its properties, not its structural strength.

PTFE is a Functional Component, Not a Structural One

PTFE is almost always used as a liner, coating, or flexible element within a stronger assembly. For example, a PTFE slide plate consists of a PTFE layer bonded to a steel backing plate. The steel provides the structural support, while the PTFE provides the low-friction, vibration-dampening surface.

Temperature and Pressure Limitations

PTFE has excellent temperature tolerance, but it is not limitless. The specific grade of PTFE and the design of the component (e.g., expansion bellow) will have clearly defined operating temperature and pressure limits that must be respected during the system design phase.

Proper Installation is Critical

The performance of PTFE components is highly dependent on their installation. Improperly fitted liners or poorly seated slide plates can fail to provide the intended protection, concentrating stress in unintended areas and undermining their purpose.

Making the Right Choice for Your Goal

To apply PTFE effectively, match the component to the primary problem you need to solve.

- If your primary focus is reducing noise and high-frequency chatter: Use PTFE liners and pads at all pipe-to-support contact points to cushion impacts.

- If your primary focus is managing thermal expansion and contraction: Implement PTFE slide plates that leverage its low-friction properties to allow for smooth axial movement.

- If your primary focus is isolating equipment or absorbing major system shock: Install PTFE expansion bellows or flexible joints directly into the pipe line.

Ultimately, integrating the correct PTFE components is a strategic investment in the long-term health and operational reliability of your piping system.

Summary Table:

| PTFE Component | Primary Function | Key Benefit |

|---|---|---|

| PTFE Liners/Pads | Cushion pipes at supports | Absorbs shock, dampens vibration & noise |

| PTFE Slide Plates | Allow smooth pipe movement | Reduces friction-induced wear from thermal expansion |

| PTFE Expansion Bellows | Absorb large-scale movement | Protects against system-wide shock & stress |

Protect your piping systems from costly vibration damage and wear. KINTEK specializes in manufacturing precision PTFE components—including custom seals, liners, slide plates, and bellows—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our custom fabrication ensures optimal performance and longevity for your critical applications. Contact our experts today to discuss your specific requirements and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance