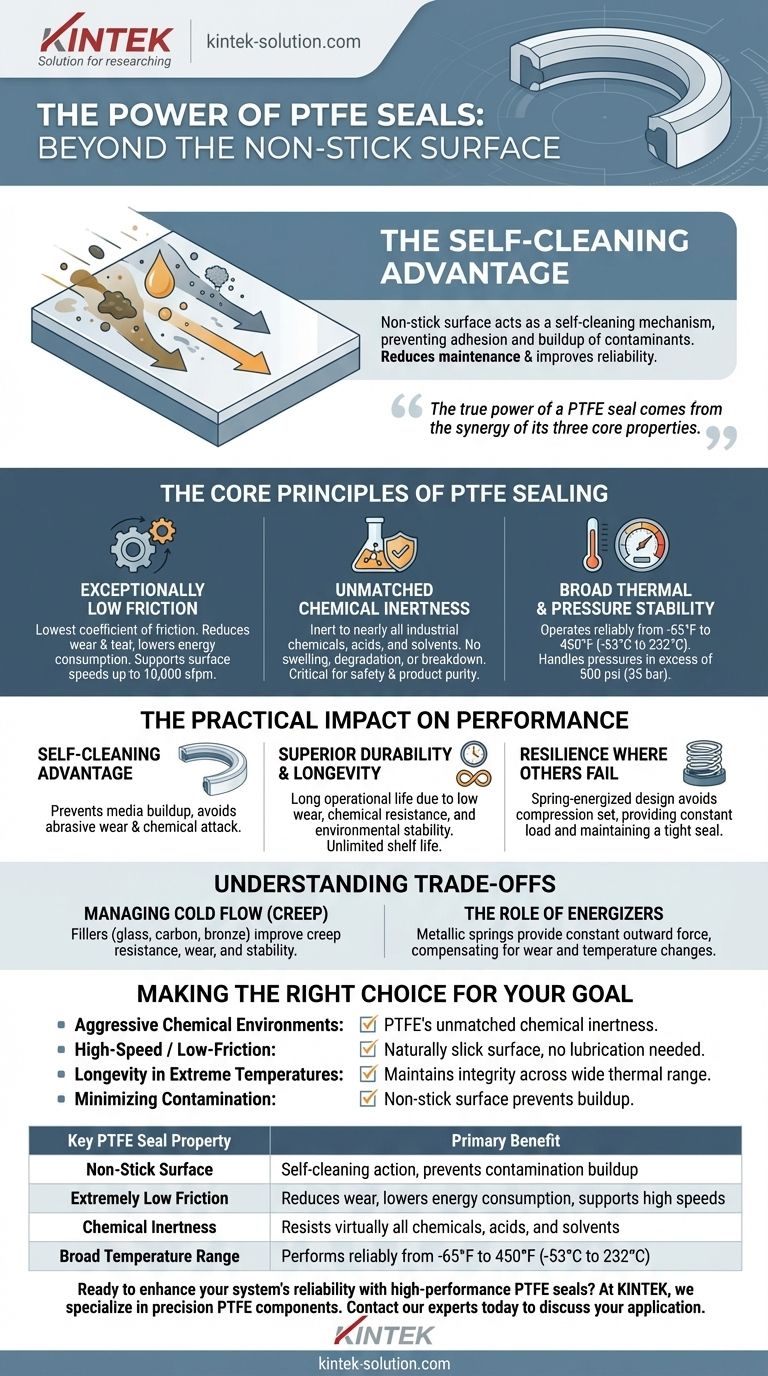

In short, the non-stick surface of PTFE acts as a self-cleaning mechanism for the seal. This property prevents the adhesion and buildup of contaminants like oils, grease, and particulate matter. As a result, the seal remains free from debris that could otherwise cause it to fail, which in turn reduces maintenance and improves operational reliability.

While its non-stick quality is a significant benefit, the true power of a PTFE seal comes from the synergy of its three core properties: extremely low friction, chemical inertness, and a wide operational temperature range.

The Core Principles of PTFE Sealing

To fully grasp the value of PTFE, it's essential to look beyond the non-stick surface and understand the material's fundamental characteristics. These properties work in concert to deliver exceptional performance in demanding conditions.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This is not just a minor benefit; it fundamentally changes how the seal performs.

This low friction reduces wear and tear on both the seal and the mating hardware, significantly extending the service life of the entire assembly. It also reduces the energy required to operate the system, improving overall efficiency, and can support surface speeds of up to 10,000 sfpm.

Unmatched Chemical Inertness

The unique molecular structure of PTFE, defined by powerful carbon-fluorine bonds, makes it inert to nearly all industrial chemicals, acids, and solvents.

This means a PTFE seal will not swell, degrade, or break down when exposed to aggressive media. This property is critical in industries like pharmaceuticals, chemical processing, and semiconductor manufacturing, where seal integrity is paramount for safety and product purity.

Broad Thermal and Pressure Stability

PTFE seals maintain their integrity and performance across an exceptionally wide range of conditions.

They can operate reliably in temperatures from -65°F to 450°F (-53°C to 232°C). Furthermore, they can be designed to handle pressures well in excess of 500 psi (35 bar), making them suitable for aerospace, automotive, and oil and gas applications.

The Practical Impact on Performance

These core properties translate directly into tangible, real-world advantages for sealed systems.

The Self-Cleaning Advantage

Returning to the initial question, the non-stick surface is a direct result of PTFE's low-energy molecular structure.

By preventing process media from building up, the seal avoids contamination that can lead to abrasive wear or chemical attack. This feature is invaluable in applications where cleanliness and consistency are critical.

Superior Durability and Longevity

The combination of low wear, chemical resistance, and environmental stability (including resistance to moisture and UV rays) gives PTFE seals a very long operational life.

This reduces the frequency of maintenance cycles and lowers the total cost of ownership. Unlike many elastomeric seals, PTFE does not degrade over time and has an unlimited shelf life.

Resilience Where Other Materials Fail

Many traditional sealing materials, like rubber elastomers, can suffer from "compression set," where they permanently deform under pressure and lose their sealing force.

Spring-energized PTFE seals are specifically designed to avoid this issue. The spring provides a constant load, ensuring the seal remains engaged even as the PTFE lip wears, providing a far more resilient solution in harsh conditions.

Understanding the Trade-offs

No material is perfect, and objectivity requires acknowledging design considerations. Understanding these factors is key to successful implementation.

Managing Cold Flow (Creep)

Unfilled, or "virgin," PTFE can be susceptible to creep—a slow deformation under sustained load. This is a well-understood characteristic of the material.

However, this is effectively managed by incorporating fillers (such as glass, carbon, or bronze) into the PTFE. These fillers dramatically improve creep resistance, wear resistance, and dimensional stability without compromising the material's core benefits.

The Role of Energizers

PTFE is a rigid plastic, not a flexible rubber. On its own, it lacks the "memory" to rebound after being compressed.

This is why high-performance PTFE seals are often spring-energized. A metallic spring inside the seal jacket provides the constant outward force needed to maintain a tight seal against the hardware, compensating for wear, pressure fluctuations, and temperature changes.

Making the Right Choice for Your Goal

Selecting a PTFE seal means choosing a material engineered for reliability in conditions where others would fail.

- If your primary focus is reliability in aggressive chemical environments: PTFE's chemical inertness is virtually unmatched, preventing seal degradation and protecting your equipment.

- If your primary focus is high-speed or low-friction performance: The naturally slick surface reduces energy loss and wear, often eliminating the need for separate lubrication.

- If your primary focus is longevity in extreme temperatures: PTFE maintains its integrity and sealing force across a wide thermal range where most elastomers would become brittle or break down.

- If your primary focus is minimizing contamination: The non-stick surface prevents media buildup, ensuring clean and consistent operation in sensitive food, medical, or pharmaceutical applications.

Ultimately, understanding PTFE's complete material profile is the key to deploying it effectively for maximum system reliability and performance.

Summary Table:

| Key PTFE Seal Property | Primary Benefit |

|---|---|

| Non-Stick Surface | Self-cleaning action prevents contamination buildup |

| Extremely Low Friction | Reduces wear, lowers energy consumption, supports high speeds |

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and solvents |

| Broad Temperature Range | Performs reliably from -65°F to 450°F (-53°C to 232°C) |

Ready to enhance your system's reliability with high-performance PTFE seals?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a sealing solution perfectly tailored to your specific chemical, thermal, and mechanical requirements.

Contact our experts today to discuss your application and discover how our PTFE seals can improve your operational efficiency and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications