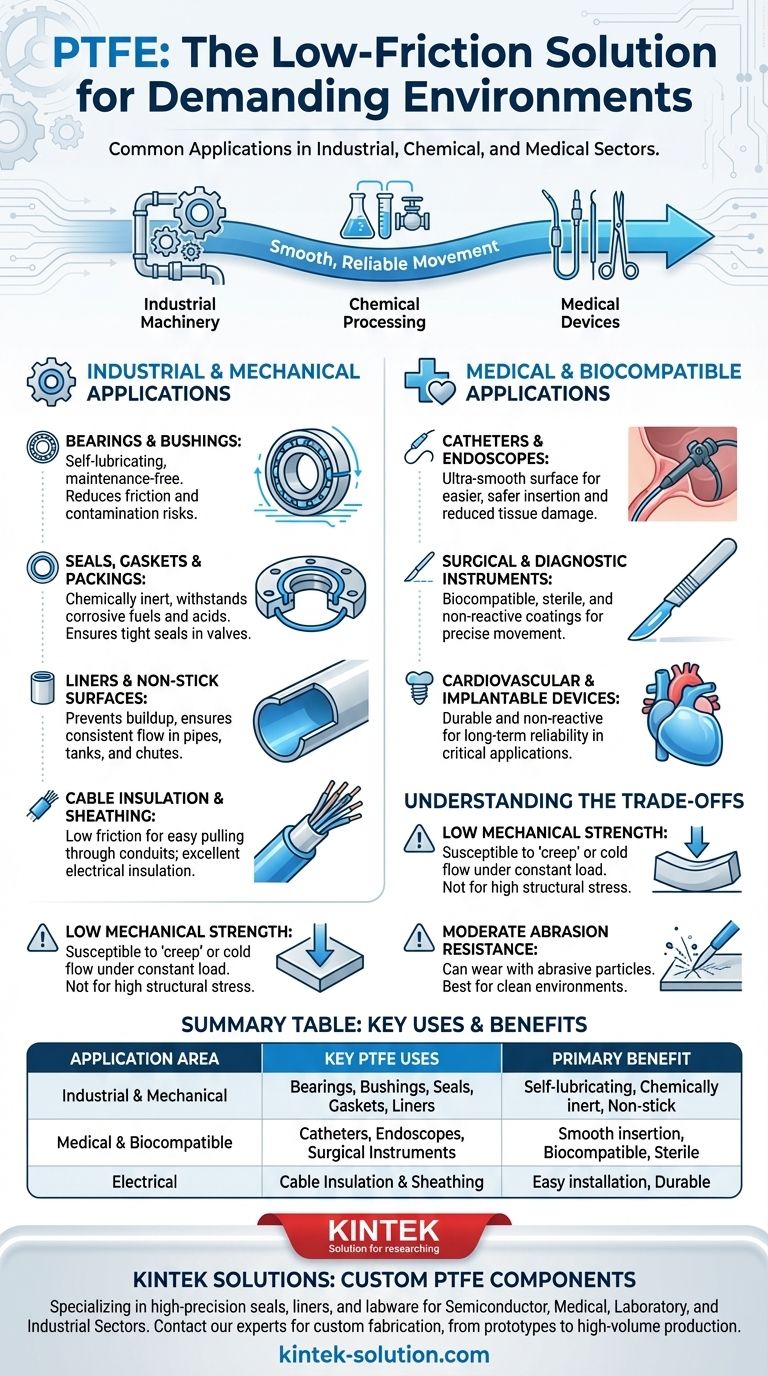

At its core, Polytetrafluoroethylene (PTFE) is most commonly applied where smooth, reliable movement is required in demanding environments. Its signature low-friction surface is used everywhere from industrial machinery and chemical processing to advanced medical devices. Key applications include self-lubricating bearings and bushings, chemically resistant seals and gaskets, non-stick coatings, and liners for catheters and surgical tools.

The true value of PTFE is not just its slipperiness, but its unique combination of near-zero friction with extreme chemical inertness and thermal stability. This makes it the default material choice for components that must move freely and reliably in harsh conditions where traditional lubrication is impossible or undesirable.

Industrial & Mechanical Applications: Where Movement Meets Hostility

The majority of PTFE applications are found in industrial settings where its properties solve critical engineering challenges related to friction, corrosion, and temperature.

Bearings, Bushings, and Wear Strips

PTFE is a premier material for components that slide against each other. Its extremely low coefficient of friction allows for the creation of self-lubricating bearings and bushings.

This eliminates the need for grease or oil, reducing maintenance and removing a potential point of contamination. Wear strips made of PTFE protect surfaces and ensure heavy equipment can move smoothly with minimal force.

Seals, Gaskets, and Packings

In chemical processing, aerospace, and hydraulic systems, effective sealing is non-negotiable. PTFE's near-total chemical inertness makes it ideal for gaskets, O-rings, and V-rings that handle corrosive fuels, acids, and industrial effluents.

Its low friction ensures a tight seal can be achieved without the components sticking or seizing, even under pressure. This is critical in valves, where PTFE packing allows for low-torque, reliable operation.

Liners and Non-Stick Surfaces

While famous for its use in non-stick cookware, this principle is applied heavily in industry. Liners for pipes, tanks, and chutes prevent viscous or sticky materials from building up, ensuring consistent flow in manufacturing plants.

In the chemical and pharmaceutical industries, PTFE stirrers and vessel liners provide a non-reactive, easy-to-clean surface.

Cable Insulation and Sheathing

The low-friction surface of PTFE makes it an excellent insulator for wiring. Its "slipperiness" is a major advantage during installation, allowing complex wire bundles to be pulled through tight conduits with minimal force and without damaging the sheathing.

Medical & Biocompatible Applications: The Hygienic Choice

In the medical field, performance must be paired with safety and sterility. PTFE’s inherent properties make it a trusted material for devices that interact with the human body.

Catheters and Endoscopes

The primary challenge for any invasive device is minimizing tissue damage. Medical-grade PTFE liners provide an incredibly smooth surface on catheters and endoscopes, allowing for easier, safer insertion into the body.

Surgical and Diagnostic Instruments

PTFE's biocompatibility ensures it does not cause adverse reactions within the body. It is frequently used to coat surgical instruments or as a liner in diagnostic equipment where frictionless, sterile movement is essential for precision.

Cardiovascular and Implantable Devices

For critical applications like cardiovascular surgery, PTFE's reliability is paramount. Its durability and non-reactive nature make it suitable for components used in minimally invasive procedures and other specialized medical devices.

Understanding the Trade-offs

Despite its remarkable advantages, PTFE is not a universal solution. An expert advisor must acknowledge its limitations to ensure it is used correctly.

Low Mechanical Strength

PTFE is a relatively soft material. It is susceptible to "creep" or cold flow, meaning it can deform over time when subjected to a constant load. It is not suitable for high-load structural components on its own.

Moderate Abrasion Resistance

While it has low friction, PTFE is not exceptionally hard. It can be worn away by abrasive particles, making it less suitable for environments with significant grit or particulate contamination unless it is filled with other materials to enhance its durability.

Making the Right Choice for Your Goal

To apply PTFE effectively, align its strengths with the primary challenge you need to solve.

- If your primary focus is self-lubricating motion: PTFE is the ideal choice for bearings, wear strips, and sliding pads where external lubricants are impractical.

- If your primary focus is sealing in a corrosive environment: Its chemical inertness makes PTFE the standard for gaskets and valve packing in the chemical, fuel, and aerospace industries.

- If your primary focus is biocompatibility and smooth insertion: Medical-grade PTFE is the definitive material for liners in catheters, endoscopes, and other invasive instruments.

- If your primary focus is supporting a high structural load: Use PTFE as a low-friction liner or coating on a stronger metal substrate rather than as a standalone part.

By understanding these applications and their underlying principles, you can confidently leverage PTFE's unique properties to solve complex engineering challenges.

Summary Table:

| Application Area | Key PTFE Uses | Primary Benefit |

|---|---|---|

| Industrial & Mechanical | Bearings, Bushings, Seals, Gaskets, Liners | Self-lubricating, Chemically inert, Non-stick |

| Medical & Biocompatible | Catheters, Endoscopes, Surgical Instruments | Smooth insertion, Biocompatible, Sterile |

| Electrical | Cable Insulation & Sheathing | Easy installation, Durable |

Need a custom PTFE component for your demanding application?

KINTEK specializes in manufacturing high-precision PTFE components like seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We combine the superior low-friction and chemical resistance of PTFE with expert custom fabrication—from prototypes to high-volume production.

Contact our PTFE experts today to discuss your specific requirements and get a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the installation methods for PTFE slide bearings? Bolting, Welding & Mortar Embedment

- How should bonded PTFE be maintained to preserve bond strength? Protect Your Critical Components from Degradation

- What are some modern applications of PTFE due to its electrical insulative properties? | High-Frequency & Extreme Environment Solutions

- What is the difference between single-acting and double-acting piston seals? Choose the Right Seal for Your Hydraulic System

- Why are PTFE-lined diaphragm valves preferred in the pharmaceutical industry? Ensure Sterility & Product Purity

- What challenges are associated with CNC milling of PTFE? Overcome Softness and Thermal Expansion

- What may be required to help PTFE seals dissipate heat more quickly? Use Conductive Fillers for High-Temp Reliability

- How should the right PTFE washer thickness be selected? Balance Sealing, Creep, and Pressure