In dry-running applications, PTFE piston rings and guide rings provide significant advantages by eliminating the need for traditional lubrication. Their inherent self-lubricating properties and extremely low coefficient of friction dramatically reduce wear, lower energy consumption, and prevent product contamination from lubricants, leading to lower operating costs and improved system reliability.

The fundamental advantage of PTFE rings in dry-running systems is their ability to provide their own lubrication. This single characteristic simplifies machine design, reduces maintenance, and ensures operational purity, making it an ideal choice for industries where contamination is not an option.

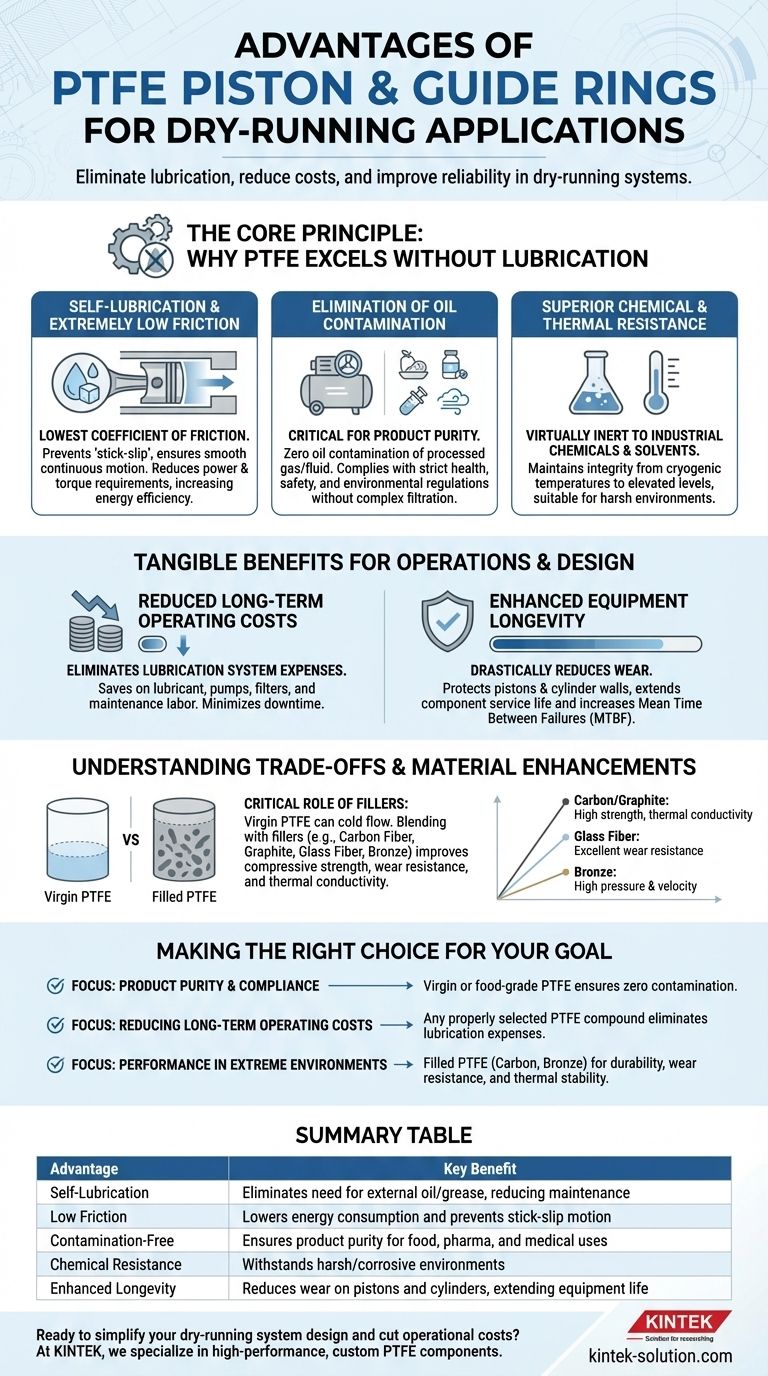

The Core Principle: Why PTFE Excels Without Lubrication

PTFE (Polytetrafluoroethylene) possesses a unique molecular structure that gives it properties perfectly suited for applications where external lubricants are impractical or forbidden. Understanding these core characteristics explains its superior performance.

Self-Lubrication and Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This is an inherent property, meaning it does not require oil or grease to operate smoothly.

This self-lubricating nature prevents the "stick-slip" phenomenon common in unlubricated systems, ensuring smooth, continuous motion. This directly translates to lower power and torque requirements, increasing the overall energy efficiency of the compressor or actuator.

Elimination of Oil Contamination

For many industries, the purity of the end product is non-negotiable. Dry-running compressors are essential in food processing, pharmaceutical manufacturing, and medical applications.

Using PTFE rings ensures that no lubricating oil can contaminate the gas or fluid being processed. This helps operators comply with strict health, safety, and environmental regulations without the need for complex and costly downstream filtration systems.

Superior Chemical and Thermal Resistance

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it an ideal material for piston and guide rings in equipment that handles corrosive gases or operates in harsh chemical environments.

Furthermore, it maintains its integrity and performance across a wide temperature range, from cryogenic conditions to elevated temperatures found in engine compartments, ensuring reliable sealing and guidance under thermal stress.

Tangible Benefits for Operations and Design

Choosing PTFE rings moves beyond theoretical material science and delivers concrete advantages in cost, maintenance, and equipment performance.

Reduced Long-Term Operating Costs

The most immediate benefit is the elimination of expenses related to lubrication systems. This includes the cost of the lubricant itself, as well as the pumps, filters, reservoirs, and piping required to manage it.

Maintenance is also simplified, as there is no need for oil changes, filter replacements, or lubricant disposal, which significantly reduces operational downtime and labor costs over the life of the machine.

Enhanced Equipment Longevity

Friction is a primary cause of wear in mechanical systems. By drastically reducing friction, PTFE rings protect both the piston and the cylinder wall from scoring and premature failure.

This extends the service life of critical components and increases the mean time between failures (MTBF), leading to more reliable and predictable machine operation.

Understanding the Trade-offs and Material Enhancements

While standard PTFE is highly effective, it's not a universal solution for every high-performance demand. Its effectiveness is often enhanced through strategic material engineering.

The Critical Role of Fillers

Pure, or "virgin," PTFE can be susceptible to cold flow (deformation under load) and has relatively low wear resistance under high pressure and velocity conditions.

To counteract this, PTFE is commonly blended with fillers like carbon fiber, graphite, glass fiber, or bronze. These reinforcing materials significantly improve the compound's compressive strength, wear resistance, and thermal conductivity, tailoring the ring's properties to the specific demands of the application.

Matching the Material to the Application

The choice of filler is critical. For instance, a carbon-filled PTFE might be used for its high strength and thermal conductivity, while a glass-filled compound might be chosen for its excellent wear resistance in non-corrosive environments.

A thorough analysis of the operating pressures, temperatures, speeds, and chemical environment is necessary to select the optimal PTFE compound for maximum performance and service life.

Making the Right Choice for Your Goal

Selecting the appropriate PTFE ring is about aligning the material's properties with your primary operational objective.

- If your primary focus is product purity and regulatory compliance: Virgin or specially-filled food-grade PTFE ensures zero oil contamination for sensitive applications in the food, medical, or pharmaceutical industries.

- If your primary focus is reducing long-term operating costs: Any properly selected PTFE compound will eliminate lubrication expenses, reduce energy consumption, and lower maintenance requirements.

- If your primary focus is performance in an extreme environment: A filled PTFE compound, such as one reinforced with carbon or bronze, will provide the necessary durability, wear resistance, and thermal stability for high-pressure or corrosive applications.

Ultimately, leveraging PTFE piston and guide rings allows you to build simpler, more efficient, and more reliable dry-running systems.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Self-Lubrication | Eliminates need for external oil/grease, reducing maintenance |

| Low Friction | Lowers energy consumption and prevents stick-slip motion |

| Contamination-Free | Ensures product purity for food, pharma, and medical uses |

| Chemical Resistance | Withstands harsh/corrosive environments |

| Enhanced Longevity | Reduces wear on pistons and cylinders, extending equipment life |

Ready to simplify your dry-running system design and cut operational costs?

At KINTEK, we specialize in manufacturing high-performance, custom PTFE components—including piston rings, guide rings, seals, and liners—for the semiconductor, medical, laboratory, and industrial sectors. Our precision-engineered PTFE solutions are tailored to your specific application requirements, from prototypes to high-volume orders, ensuring optimal performance, purity, and reliability.

Contact us today to discuss how our PTFE components can enhance your equipment's efficiency and longevity!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs