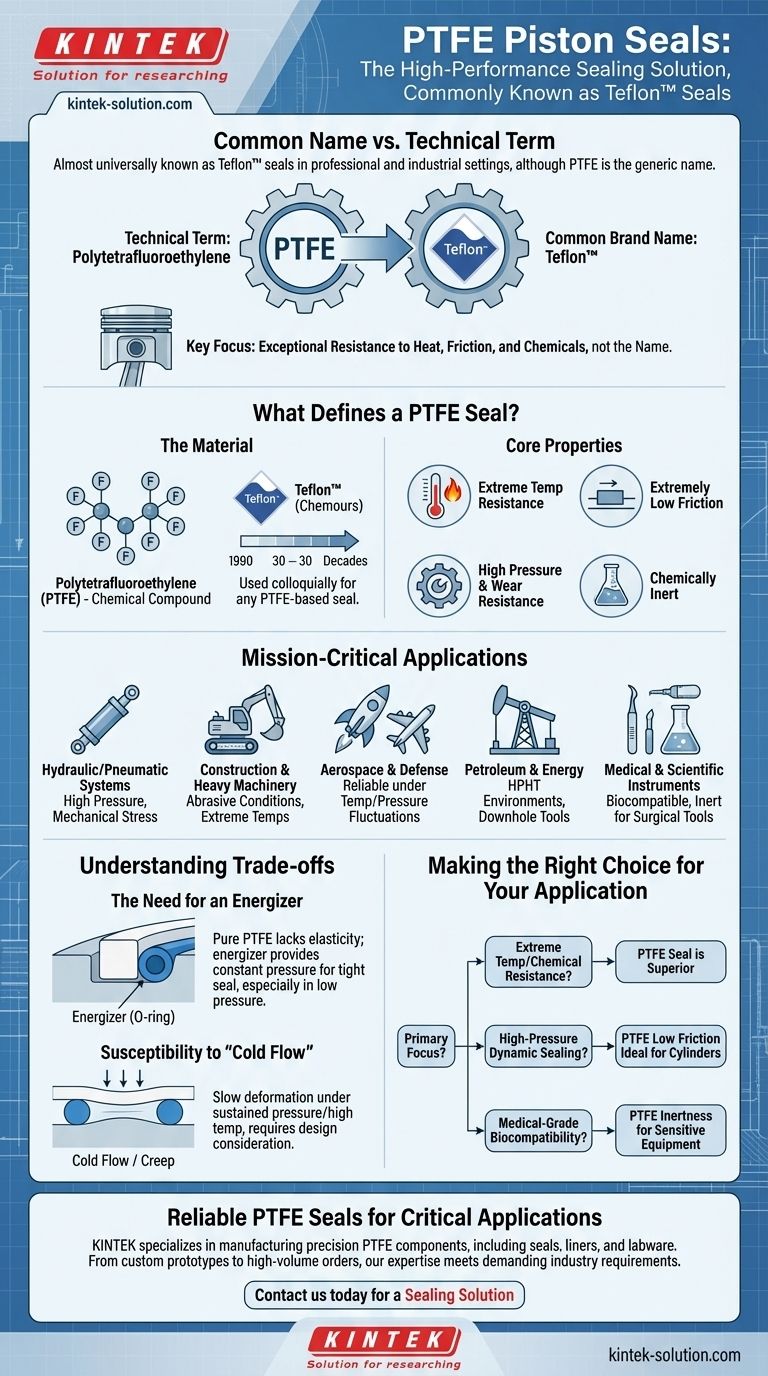

In professional and industrial settings, PTFE piston seals are almost universally known by the well-known brand name Teflon™ seals. Polytetrafluoroethylene (PTFE) is the generic name for the high-performance fluoropolymer, while Teflon™ is the registered trademark for that material. This distinction is similar to how we refer to adhesive bandages as Band-Aids.

While the technical term is a PTFE seal, the common name is a Teflon seal. The real importance, however, lies not in the name but in the material's exceptional resistance to heat, friction, and chemicals, making it indispensable in high-stress industrial, aerospace, and medical applications.

What Defines a PTFE (Teflon) Seal?

The name is just the beginning. The reason these seals are specified in critical applications is due to the inherent properties of the PTFE material itself.

The Material vs. The Brand

Polytetrafluoroethylene (PTFE) is the specific chemical compound. Teflon™ is the brand name first created by the DuPont company (now Chemours).

Over decades, the brand name became so dominant in the market that it is now used colloquially to refer to any PTFE-based seal, regardless of the manufacturer.

Core Properties

PTFE seals are chosen for their unique combination of characteristics, which outperform standard elastomers in certain conditions.

Key properties include exceptional wear and temperature resistance, making them ideal for high-pressure and high-stress operations. They also exhibit extremely low friction and are chemically inert.

Where Are These Seals Mission-Critical?

The unique advantages of PTFE make these seals the default choice in environments where failure is not an option. Their reliability under duress is paramount.

Hydraulic and Pneumatic Systems

These seals are workhorses in hydraulic cylinders and pneumatic actuators, especially where high pressure and mechanical stress are constant factors.

Construction and Heavy Machinery

In equipment like excavators and loaders, PTFE seals provide the durability needed to withstand abrasive conditions and extreme operating temperatures without degrading.

Aerospace and Defense

From aircraft hydraulic systems and engines to pumps and brakes, the reliability of PTFE seals under extreme temperature fluctuations and pressures is essential for safety and performance.

Petroleum and Energy

PTFE seals are critical in downhole tools and subsea equipment, especially in High-Pressure High-Temperature (HPHT) environments where lesser materials would fail catastrophically.

Medical and Scientific Instruments

Due to its biocompatibility and inert nature, PTFE is used for seals in surgical tools, autoclaves, and sensitive analytical equipment like hematology analyzers.

Understanding the Trade-offs

No single material is perfect for every situation. While PTFE is a superior performer, it has distinct characteristics that engineers must account for in their designs.

The Need for an Energizer

Pure PTFE is a relatively rigid material and lacks the "memory" or elasticity of rubber. Because of this, PTFE seals are almost always designed with an energizer.

This energizer, typically a rubber O-ring, sits in a groove behind the PTFE ring. It provides the constant, light pressure needed to ensure the PTFE element maintains a tight seal, especially in low-pressure situations.

Susceptibility to "Cold Flow"

Under sustained pressure and high temperatures, PTFE can slowly deform over time. This phenomenon, known as creep or cold flow, is a critical design consideration for engineers to ensure long-term seal integrity.

Making the Right Choice for Your Application

Selecting a PTFE seal is a decision driven by the demands of the operating environment.

- If your primary focus is extreme temperature and chemical resistance: PTFE is the superior choice for environments where other elastomers would quickly degrade.

- If your primary focus is high-pressure dynamic sealing: The extremely low friction of PTFE makes it ideal for piston and rod seals in demanding hydraulic or pneumatic cylinders.

- If your primary focus is medical-grade biocompatibility: The inert nature of PTFE makes it a default material for surgical tools and sensitive analytical equipment.

Recognizing that "Teflon seal" refers to the high-performance material PTFE empowers you to specify the correct component for the most demanding engineering challenges.

Summary Table:

| Common Name | Technical Name | Key Property | Primary Application |

|---|---|---|---|

| Teflon™ Seal | PTFE Seal | Extreme Chemical & Temperature Resistance | Hydraulic/Pneumatic Systems |

| Teflon™ Seal | PTFE Seal | Low Friction & High Wear Resistance | Aerospace & Defense |

| Teflon™ Seal | PTFE Seal | Biocompatibility & Inertness | Medical & Scientific Instruments |

Need reliable, high-performance PTFE seals for your critical application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need custom prototypes or high-volume orders, our expertise ensures your seals meet the demanding requirements of your industry.

Contact us today to discuss your specific needs and let us provide you with a sealing solution that delivers unmatched durability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the standard sheet sizes for PTFE? Optimize Your Material Selection

- How do PTFE lip seals perform in turbocharger applications? Superior Sealing for Extreme High-Speed Environments

- What are the standard gasket choices for PTFE rotary lip seals? Ensure Total System Reliability

- What industrial applications commonly use PTFE gaskets? Solve Your Toughest Sealing Challenges

- What industries commonly use PTFE valves and components? Essential for Chemical & Purity Applications

- What additional properties do PTFE O-rings require besides thermal resistance? Master Chemical and Mechanical Sealing

- What are the non-stick properties of PTFE plugs useful for? Ensuring Purity & Easy Maintenance

- What are the benefits of PTFE sealed ball bearings? Achieve Peak Performance with Low Friction & Zero Maintenance