At their core, PTFE guide strips serve a critical role in dynamic systems by guiding moving components and preventing damaging metal-to-metal contact. Their primary application is within hydraulic and pneumatic cylinders, where they act as bearing elements for pistons and rods, absorbing side loads and protecting the integrity of the system's seals.

The essential purpose of a PTFE guide strip is not to seal, but to bear radial loads and guide components with minimal friction. This protects more delicate sealing elements and expensive metal parts, ultimately extending the service life and improving the performance of the entire assembly.

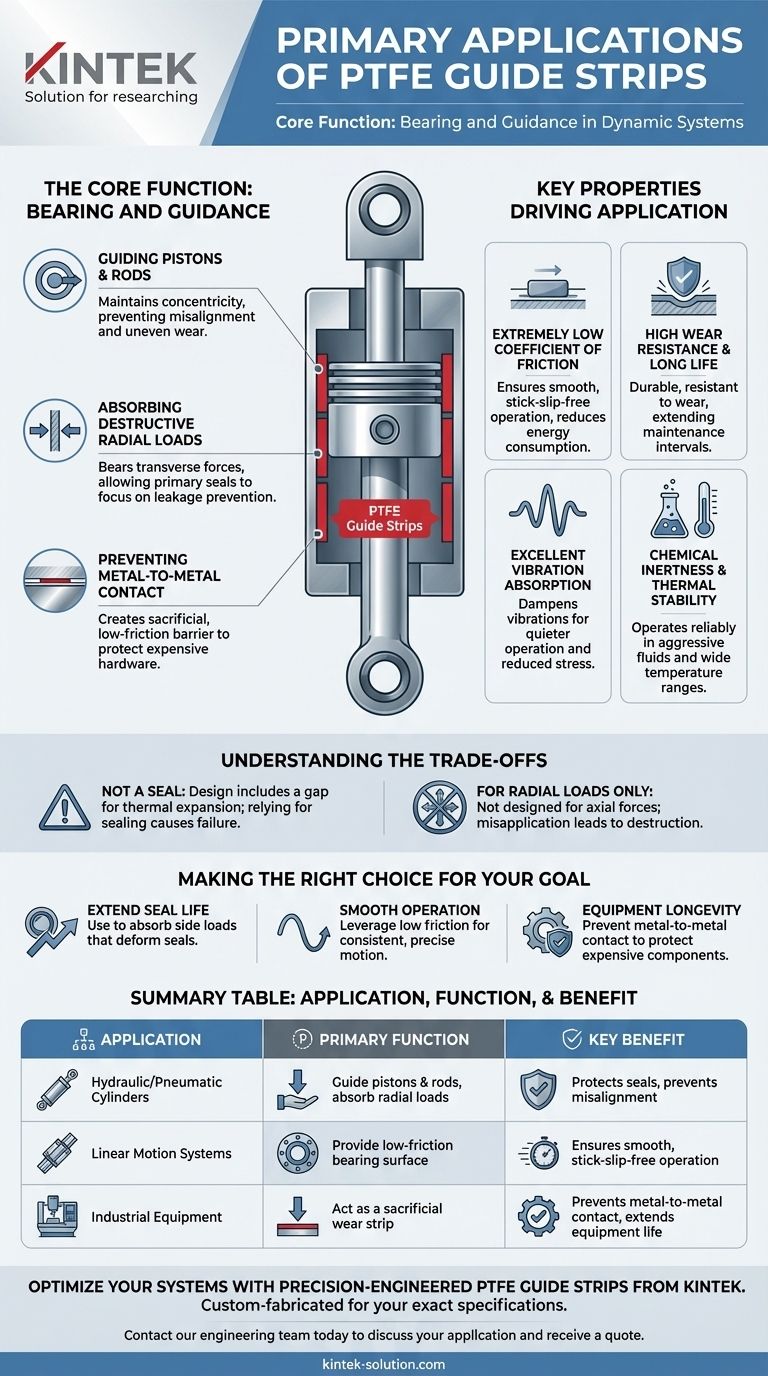

The Core Function: Bearing and Guidance

PTFE guide strips are fundamental components for ensuring the reliability and longevity of linear motion systems. Their function is precise and protective.

Guiding Pistons and Piston Rods

In hydraulic and pneumatic systems, guide strips are installed on pistons and in rod glands. They maintain the concentricity of the piston within the cylinder bore and the rod within the gland.

This precise guidance is crucial for preventing misalignment, which can lead to uneven wear and catastrophic failure.

Absorbing Destructive Radial Loads

The primary mechanical job of a guide strip is to absorb transverse forces, also known as radial loads. These side loads are common in industrial equipment and can quickly destroy a primary seal if not managed.

By bearing these forces, the guide strip allows the main seal (like a U-cup or O-ring) to focus exclusively on its job: preventing fluid or gas leakage.

Preventing Metal-to-Metal Contact

Without guide strips, the metal piston head would rub directly against the metal cylinder bore. This contact leads to scoring, galling, and the generation of damaging metal particles within the system.

PTFE strips create a sacrificial, low-friction barrier that prevents this deterioration, protecting the most expensive and critical hardware components.

Key Properties Driving Application

The choice of PTFE for guide strips is not arbitrary; it is driven by a unique combination of material properties that make it exceptionally well-suited for this role.

Extremely Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any solid material. This ensures smooth, stick-slip-free operation, even at very low speeds or after long periods of standstill.

This property reduces the energy required to move the component and ensures predictable, consistent motion.

High Wear Resistance and Long Life

The material is inherently durable and resistant to wear, which translates directly to a long service life. This reduces maintenance intervals and equipment downtime.

Excellent Vibration Absorption

PTFE guide strips can dampen vibrations within the system. This leads to quieter operation and reduces mechanical stress on other components.

Chemical Inertness and Thermal Stability

Made from virgin PTFE resin, these strips are chemically inert. They can operate reliably in systems with aggressive hydraulic fluids or in corrosive industrial environments without degrading. They also maintain their properties across a wide range of temperatures.

Understanding the Trade-offs

While highly effective, it is critical to understand the specific role and limitations of PTFE guide strips to apply them correctly.

A Guide, Not a Primary Seal

A common misconception is that guide strips contribute to sealing. They do not. Their design includes a gap to allow for thermal expansion and prevent pressure trapping.

Relying on a guide strip for any sealing function will result in system failure. They are purely a bearing and guidance element that protects the seal.

Designed for Radial Loads Only

These components are engineered exclusively to handle forces perpendicular to the direction of motion (radial loads). They are not designed to withstand forces along the axis of motion (axial loads).

Misapplying them in a thrust-bearing capacity will lead to their rapid destruction.

Making the Right Choice for Your Goal

When integrating PTFE guide strips, align your choice with your primary engineering objective.

- If your primary focus is extending seal life: Use guide strips to absorb side loads that would otherwise deform and destroy your primary sealing elements.

- If your primary focus is smooth, stick-slip-free operation: The exceptionally low friction of PTFE ensures consistent motion and eliminates jerky movements, enhancing system precision.

- If your primary focus is equipment longevity: Implementing guide strips is a cost-effective strategy to prevent direct metal-to-metal contact, protecting expensive cylinder bores and rods from wear.

By correctly applying PTFE guide strips, you are investing in the stability, efficiency, and durability of your entire mechanical system.

Summary Table:

| Application | Primary Function | Key Benefit |

|---|---|---|

| Hydraulic/Pneumatic Cylinders | Guide pistons & rods, absorb radial loads | Protects seals, prevents misalignment |

| Linear Motion Systems | Provide low-friction bearing surface | Ensures smooth, stick-slip-free operation |

| Industrial Equipment | Act as a sacrificial wear strip | Prevents metal-to-metal contact, extends equipment life |

Optimize your hydraulic, pneumatic, or linear motion systems with precision-engineered PTFE guide strips from KINTEK.

Our custom-fabricated PTFE components are designed to:

- Protect critical seals by absorbing destructive radial loads.

- Ensure smooth, reliable operation with extremely low friction.

- Extend equipment service life by preventing costly metal-to-metal wear.

Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, KINTEK prioritizes precision production to meet your exact specifications.

Contact our engineering team today to discuss your application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability