For machining PTFE, the most recommended tools are extremely sharp, uncoated carbide or high-speed steel (HSS) cutters. These tools should feature polished cutting edges and large, positive rake angles. This specific combination is designed to shear the soft material cleanly rather than pushing it, which minimizes friction, heat generation, and material deformation.

The core challenge in machining Polytetrafluoroethylene (PTFE) is not its hardness, but its softness, low thermal conductivity, and high thermal expansion. Success depends less on the tool material alone and more on a complete system—tool geometry, sharpness, and machining parameters—all optimized to achieve a clean slicing action with minimal heat input.

Why Machining PTFE is a Unique Challenge

PTFE behaves very differently from metals and even other plastics during machining. Understanding its core properties is essential to understanding why specific tools and techniques are required.

It's Soft and "Gummy"

PTFE is a soft material that tends to deform or tear under pressure rather than chip cleanly like a metal. An incorrect tool will "plow" through the material, creating a poor surface finish and significant burrs.

It Has Poor Thermal Conductivity

The material does not dissipate heat well. Any friction from the cutting process causes heat to build up rapidly right at the tool edge, which can easily cause the PTFE to melt and foul the cutter.

It Expands Significantly with Heat

PTFE has a very high coefficient of thermal expansion. Even a small temperature increase during machining can cause the part to expand, making it impossible to hold tight dimensional tolerances. The part may be within spec while warm but out of spec once it cools.

Selecting the Right Cutting Tool: A Deeper Look

The ideal cutting tool for PTFE is designed to counteract the challenges mentioned above. The focus is entirely on reducing friction and cutting forces.

Tool Material: Carbide and HSS

Carbide-tipped or solid carbide tools are often preferred. Their primary advantage is the ability to be ground to a very sharp, long-lasting edge, which is critical for a clean shearing action.

High-Speed Steel (HSS) is also an excellent and widely used option. Like carbide, it can be honed to the necessary sharpness for PTFE.

The Critical Role of Tool Geometry

The shape and condition of the tool are more important than the material it's made from.

Extreme Sharpness and Polished Edges are non-negotiable. A razor-sharp, polished or lapped edge slices through the material with minimal force, reducing friction and heat. Dull tools will immediately cause problems.

Positive Rake Angles are essential. A large, positive rake angle (often in the 0–15 degree range) helps lift the PTFE chip and guide it away from the workpiece efficiently. This drastically reduces cutting pressure and heat generation.

The Uncoated Advantage is a key insight. While coatings like Titanium Nitride (TiN) are beneficial for machining hard metals, they can increase friction when cutting soft PTFE. A simple, uncoated but highly polished tool surface is superior for this application.

Mastering the Machining Parameters

The right tool is only effective when paired with the right process parameters. Your goal is to get the tool in and out of the cut before heat has a chance to build up in the part.

High Speeds and Moderate Feeds

High cutting speeds (e.g., 200–500 m/min or 656–1640 ft/min) are recommended. This allows the sharp edge to perform a clean shear before significant heat can be transferred to the workpiece.

Pair this with a moderate feed rate (e.g., 0.1–0.2 mm/rev). This ensures consistent material removal without dwelling in one spot, which would generate excess heat.

Shallow Depth of Cut

Use a shallow depth of cut (e.g., 0.5–1.5 mm). Taking light passes minimizes the stress on the material, preventing it from distorting, flexing away from the cutter, or building up excessive heat.

The Importance of Cooling

Using a coolant or lubricant can be very effective in managing the small amount of heat that is generated. This helps stabilize the part's temperature and improve dimensional accuracy.

Common Pitfalls to Avoid

Even with the right setup, mistakes are common due to PTFE's unique nature.

Material Deformation, Not Cutting

If you see heavy burring or a "smeared" surface finish, it is a clear sign that your tool is dull or has the wrong geometry. The tool is pushing the material aside instead of cutting it.

Heat Buildup and Melting

Visible melting or chips sticking to the tool indicates too much friction. This is typically caused by a dull tool, the wrong coating, or incorrect parameters (e.g., speed too low or feed rate too high).

Failing to Hold Tolerances

Remember that PTFE moves with temperature. A good rule of thumb for standard PTFE is a tolerance of +/- 0.001 inch per inch of dimension. Achieving anything tighter requires exceptional process control and a stable environment.

Making the Right Choice for Your Goal

Your specific tooling and process choices should align with your desired outcome.

- If your primary focus is high precision and tight tolerances: Use extremely sharp, uncoated carbide tools in a CNC machine and apply coolant to maintain thermal stability.

- If your primary focus is good surface finish and general fabrication: Emphasize a razor-sharp HSS or carbide tool with a high positive rake and ensure your cutting speeds are high.

- If you are experiencing melting or heavy burring: Your first step should always be to inspect the tool for sharpness and ensure it is uncoated, then verify your speeds and feeds.

Ultimately, successful PTFE machining is a process of finesse that prioritizes sharpness and heat management over force.

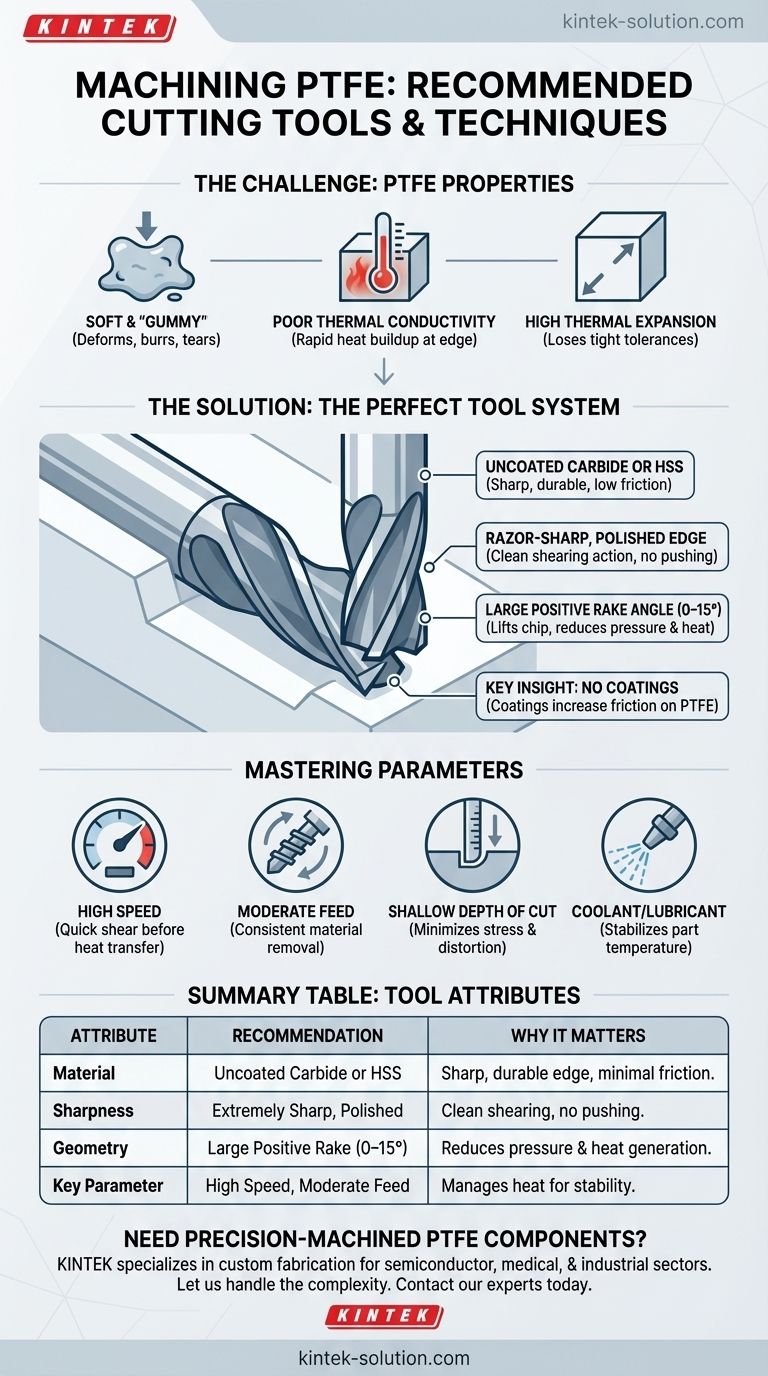

Summary Table:

| Tool Attribute | Recommendation for PTFE | Why It Matters |

|---|---|---|

| Material | Uncoated Carbide or HSS | Provides a sharp, durable edge with minimal friction. |

| Sharpness | Extremely Sharp, Polished Edge | Ensures a clean shearing action instead of pushing the material. |

| Geometry | Large Positive Rake Angle (0–15°) | Reduces cutting pressure and heat generation by efficiently lifting the chip. |

| Key Parameter | High Speed, Moderate Feed, Shallow Cut | Manages heat buildup to maintain dimensional stability. |

Need Precision-Machined PTFE Components?

Machining PTFE to exact specifications requires expertise and the right tools. KINTEK specializes in the custom fabrication of high-quality PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We leverage our deep material knowledge and precision production capabilities to deliver parts that meet your tightest tolerances, from prototypes to high-volume orders.

Let us handle the complexity. Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability