Expanded PTFE (ePTFE) gaskets derive their exceptional creep resistance from their unique, multi-directional fibrous structure created during the expansion process. This internal network of interconnected fibers and nodes provides mechanical strength, preventing the material from flowing or thinning out under the sustained compressive load required for a reliable, long-term seal.

The superior creep resistance of ePTFE is not inherent to the base PTFE material alone; it is a direct result of the expansion process. This process creates a strong, interlocking fibrous web that mechanically locks the material in place, ensuring dimensional stability under pressure and temperature.

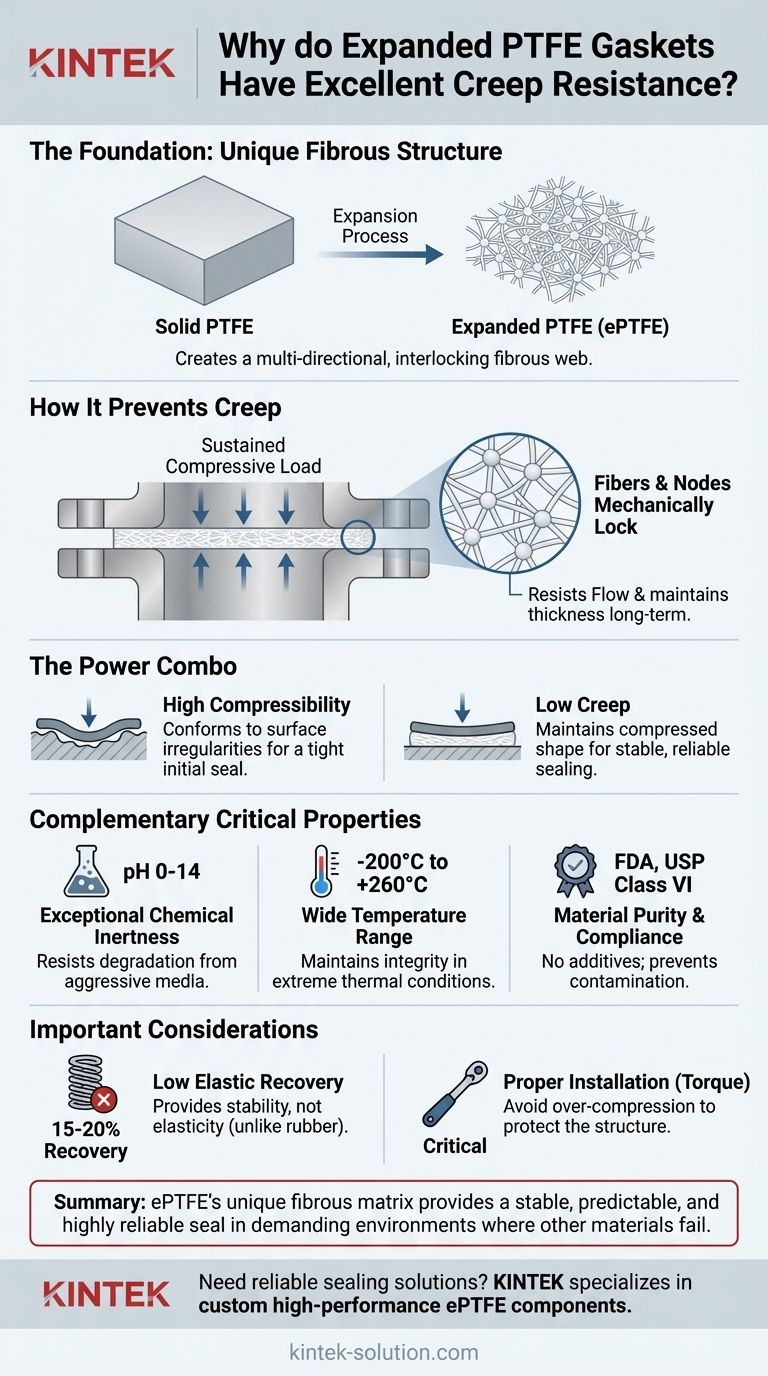

The Foundation of ePTFE's Stability: A Unique Fibrous Structure

To understand why ePTFE resists creep, we must first look at how its structure differs from standard, solid PTFE.

From Solid Block to Interlocking Web

Standard PTFE is a solid polymer. Expanded PTFE is created by physically stretching this material under specific conditions. This action transforms the solid block into a microporous structure composed of strong, crystalline fibers interconnected by solid nodes.

This resulting material is not a uniform solid but an intricate, web-like matrix.

How This Structure Prevents Creep

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress. For a gasket, this means thinning out over time, which reduces bolt load and can lead to leaks.

The fibrous web of ePTFE directly counters this. When compressed between two flanges, the fibers and nodes lock against each other. This creates a mechanically stable structure that resists the tendency to flow outward and away from the applied load.

High Compressibility, Low Creep

ePTFE exhibits a powerful combination of two distinct properties. Its high compressibility allows it to conform easily to fill surface irregularities, scratches, and voids on a flange face, creating a tight initial seal.

Once compressed, however, its low creep characteristic takes over. The locked fibrous structure ensures the gasket maintains its compressed thickness and shape, providing a stable and reliable seal for the long term.

Critical Properties That Complement Creep Resistance

Creep resistance alone is not enough to make a great gasket. ePTFE's reliability comes from a combination of elite properties that work in concert.

Exceptional Chemical Inertness

ePTFE is resistant to nearly all chemicals across the entire 0-14 pH range. It is only affected by rare substances like molten alkali metals and elemental fluorine.

This means the gasket material itself will not degrade when exposed to aggressive media, a common cause of seal failure in other materials.

Wide Operational Temperature Range

The material maintains its integrity and sealing capability in extreme temperatures, performing reliably for long durations from -200℃ to +260℃ (-328°F to +500°F).

Since high temperatures accelerate creep in most polymers, ePTFE's thermal stability is crucial to maintaining its creep resistance in demanding applications.

Material Purity and Compliance

Because the expansion process requires no additives, ePTFE maintains the purity of virgin PTFE. This makes it compliant with stringent FDA and USP Class VI standards for food, beverage, and pharmaceutical use.

This purity prevents contamination of process media and ensures the material's properties remain consistent and predictable.

Understanding the Trade-offs and Material Behavior

While powerful, ePTFE is not a universal solution. Understanding its specific behavior is key to using it correctly.

Creep Resistance vs. Elastic Recovery

ePTFE's strength is its ability to maintain its compressed shape, not to spring back. It has a relatively low elastic recovery rate (typically 15-20%) compared to rubber or other elastomers.

Its primary function is to conform and hold that shape with minimal deformation over time. It provides stability, not elasticity.

Importance of Proper Installation

The high compressibility that makes ePTFE so effective at sealing also makes it susceptible to over-compression during installation. Applying excessive torque can damage the delicate fibrous structure, permanently compromising its ability to resist creep and maintain a seal.

Following manufacturer-specified torque values is absolutely critical to leveraging the material's benefits.

Making the Right Choice for Your Sealing Application

Based on these properties, ePTFE excels in specific scenarios where long-term stability is the primary concern.

- If your primary focus is long-term reliability in high-temperature or corrosive chemical service: ePTFE's combination of thermal stability, chemical inertness, and elite creep resistance makes it an ideal choice.

- If your application involves irregular or damaged flange surfaces: The high compressibility of ePTFE allows it to conform perfectly, creating an effective initial seal that its creep resistance will maintain over time.

- If your system requires high elastic recovery for frequent dynamic movement: You might consider an elastomeric material, as ePTFE's strength lies in dimensional stability under a constant load, not spring-back.

Ultimately, the unique fibrous matrix of expanded PTFE provides a stable, predictable, and highly reliable seal in demanding environments where other materials would quickly creep and fail.

Summary Table:

| Key Property | Benefit for Creep Resistance & Sealing |

|---|---|

| Multi-Directional Fibrous Structure | Mechanically locks the material in place, preventing flow under load. |

| High Compressibility | Conforms to irregular flange surfaces for a perfect initial seal. |

| Wide Temperature Range (-200°C to +260°C) | Maintains integrity and stability in extreme thermal conditions. |

| Exceptional Chemical Inertness | Resists degradation from aggressive media, preserving the structure. |

Need a gasket that won't fail under pressure?

KINTEK specializes in manufacturing high-performance, custom-expanded PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production ensures your ePTFE gaskets deliver the superior creep resistance and long-term reliability detailed in this article.

We offer custom fabrication from prototypes to high-volume orders, tailoring the solution to your specific application's demands.

Contact KINTEK today to discuss your sealing challenges and discover how our PTFE solutions can enhance your system's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does gland packing function in sealing systems? Achieve Reliable, Controlled Sealing

- What are the advantages of machining Teflon? Unlock Superior Precision and Complex Designs

- What are the uses of Micro Powder PTFE? The Ultimate Additive for Friction & Wear Reduction

- What is the hardness rating of Teflon balls? Understanding PTFE's Softness for Optimal Use

- How does CNC turning work for PTFE, and what precautions are necessary? Achieve Precision Machining

- What is the pH range for both PTFE and graphite packing? Selecting the Right Material for Extreme Conditions

- How do PTFE coated fasteners perform in marine and offshore environments? Superior Corrosion Protection for Critical Assets

- Why are PTFE liners ideal for handling sticky materials? Maximize Yield and Simplify Cleaning