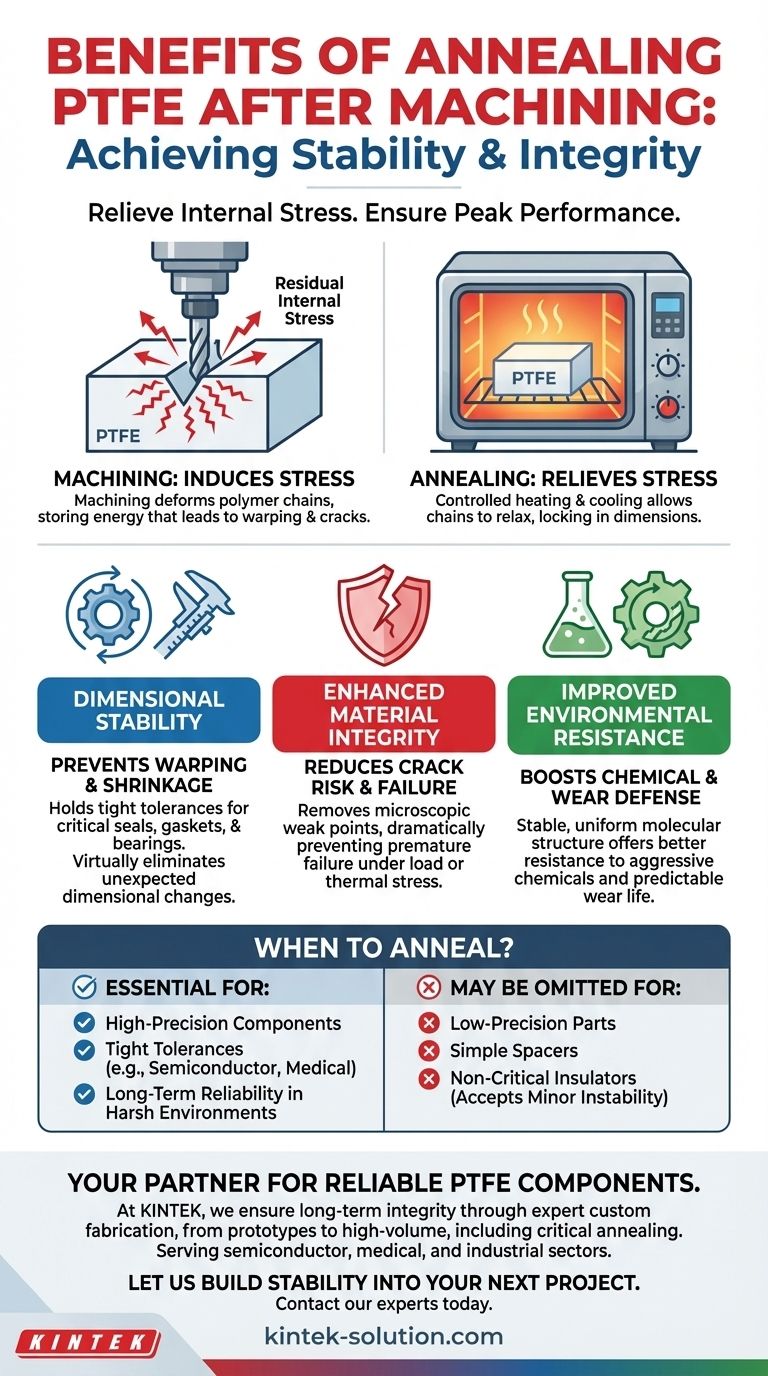

In short, annealing PTFE after machining is a critical step for stabilizing the material and ensuring the finished part performs as designed. This thermal treatment relieves internal stresses induced during the machining process, which reduces the risk of surface cracks, minimizes post-machining shrinkage, and improves overall chemical and wear resistance.

The core reason for annealing machined PTFE is to achieve dimensional stability and material integrity. Machining introduces stress that can cause a part to warp, crack, or fail prematurely; annealing removes that stress, locking in the part's final dimensions and maximizing its lifespan.

The Core Problem: Stress Induced During Machining

Polytetrafluoroethylene (PTFE) is a relatively soft polymer. The energy imparted by cutting tools during machining doesn't just remove material; it also deforms the polymer chains at and below the surface, creating residual internal stresses.

Why Internal Stress is a Problem

These stored stresses are invisible but represent a significant risk. Over time, or when exposed to thermal cycles, this stored energy will try to release itself.

This release manifests as dimensional changes (warping or shrinking) or even material failure through stress cracking, compromising the part's function.

Key Benefits of Post-Machining Annealing

Annealing is a controlled heating and cooling process that allows the polymer chains to relax into a more stable, lower-energy state. This systematically removes the residual stress created during machining.

Achieving True Dimensional Stability

The most immediate benefit of annealing is preventing the part from changing shape after it's been measured and approved.

By relieving stress, annealing virtually eliminates unexpected shrinkage or warping. This is the key to holding tight tolerances on critical components like seals, gaskets, and bearings.

Enhancing Material Integrity

Internal stress creates microscopic points of weakness within the PTFE. These can grow into larger surface cracks over time, especially when the part is under mechanical load or thermal stress.

Annealing removes these weak points, dramatically reducing the likelihood of cracking and preventing premature failure in the field.

Improving Environmental Resistance

A stable, unstressed molecular structure is inherently more robust. Annealed PTFE exhibits improved resistance to both chemical attack and physical wear.

The more uniform, relaxed structure presents a more formidable barrier to aggressive chemicals and wears more predictably over its service life.

Understanding the Trade-offs

While highly beneficial, annealing is an additional process step that adds time and cost to production. It requires access to a calibrated oven and a well-documented procedure for heating, soaking, and cooling.

When is Annealing Not Necessary?

For low-precision components where dimensional stability is not a primary concern—such as simple spacers or non-critical insulators—the added cost of annealing may not be justified.

However, forgoing this step on a high-performance part is a significant risk that often leads to costly failures and rework down the line.

Making the Right Choice for Your Application

Ultimately, the decision to anneal should be based on the demands of the final application.

- If your primary focus is tight tolerances: Annealing is essential to prevent the part from moving out of spec after final inspection.

- If your primary focus is long-term reliability in a harsh environment: Annealing is critical for preventing stress-related failure and improving chemical and wear resistance.

- If your primary focus is a simple, low-cost component: You may be able to omit annealing, but you must accept the risk of minor dimensional instability.

Investing in a proper annealing process is the most effective way to ensure your machined PTFE components deliver the stability and performance they were designed for.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Dimensional Stability | Prevents warping & post-machining shrinkage to hold tight tolerances. |

| Enhanced Material Integrity | Reduces risk of surface cracks and premature part failure. |

| Improved Environmental Resistance | Boosts performance against chemical attack and physical wear. |

Need dimensionally stable and reliable PTFE components?

At KINTEK, we understand that the final performance of a PTFE part depends on precise machining and proper post-processing like annealing. We don't just manufacture PTFE seals, liners, and labware—we ensure their long-term integrity. Our expertise in custom fabrication, from prototypes to high-volume orders, includes critical steps like annealing to guarantee your components for the semiconductor, medical, and industrial sectors perform as designed.

Let us build stability into your next project. Contact our experts today to discuss your requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications