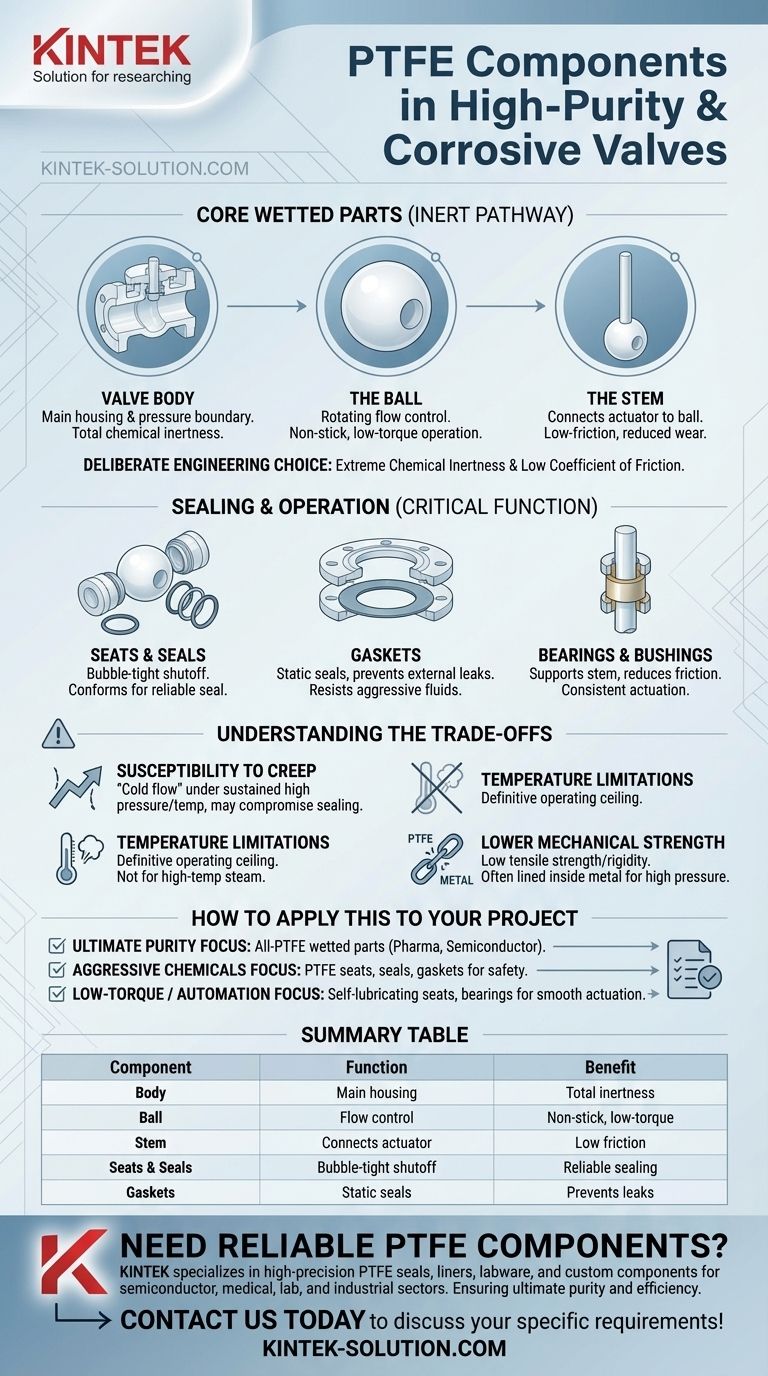

In valves designed for high-purity or corrosive applications, the main components constructed from Polytetrafluoroethylene (PTFE) are typically the parts that come into direct contact with the fluid medium. This includes the valve body, stem, ball, and ports, which form the primary flow path. PTFE is also essential for critical sealing components like seats, gaskets, and various rings that ensure leak-free operation.

The use of PTFE in valve construction is a deliberate engineering choice. Its value lies not just in a single component, but in how its unique properties—extreme chemical inertness and a very low coefficient of friction—solve critical challenges in both the valve's main structure and its internal sealing mechanisms.

The Role of PTFE in Core Wetted Parts

When a valve is described as a "PTFE valve," it often means the key components that touch the internal fluid (the "wetted parts") are made entirely of PTFE. This provides a completely inert pathway.

Valve Body

The valve body is the main housing that contains all other components. Making it from PTFE ensures that the entire external pressure boundary is resistant to virtually all industrial chemicals.

The Ball

The ball is the rotating element that controls the flow. A PTFE ball provides a non-stick surface, preventing media from adhering to it and ensuring clean operation. Its low friction also allows for smooth, low-torque turning.

The Stem

The stem connects the actuator or handle to the ball. A PTFE stem moves with minimal friction against the valve's seals, reducing wear and the force needed to operate the valve.

PTFE's Critical Function in Sealing and Operation

Beyond the main structural parts, PTFE is the material of choice for components that must seal, flex, or slide. Its combination of chemical resistance and self-lubricating properties is unmatched in these roles.

Seats and Seals

Valve seats are the seals that press against the ball to create a bubble-tight shutoff in the closed position. PTFE's flexibility allows it to conform perfectly to the ball, ensuring a reliable seal. Other common sealing components include O-rings and V-rings.

Gaskets

Gaskets are used to create static seals between fixed parts of the valve, such as between the body and bonnet. PTFE gaskets prevent external leaks, especially when handling aggressive fluids that would destroy typical elastomer seals.

Bearings and Bushings

In many valve designs, bearings or bushings are used to support the stem and reduce rotational friction. PTFE is ideal for this as a self-lubricating material, ensuring consistent and easy actuation over the valve's life.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not without limitations. Understanding these is key to proper application.

Susceptibility to Creep

PTFE is a relatively soft material and can be prone to "cold flow," or creep. Under sustained high pressure and temperature, it can slowly deform, which may compromise sealing integrity over time.

Temperature Limitations

While stable at high temperatures compared to many plastics, PTFE has a definitive operating ceiling. It is not suitable for high-temperature steam or other applications that exceed its material limits, where metals would be required.

Lower Mechanical Strength

Compared to metals, PTFE has low tensile strength and rigidity. For this reason, it is often used as a liner inside a stronger metal body for high-pressure applications, combining the strength of metal with the chemical resistance of PTFE.

How to Apply This to Your Project

Your choice of valve material should be driven entirely by the demands of your specific application.

- If your primary focus is ultimate purity: A valve with all-PTFE wetted parts (body, ball, stem) is the correct choice for industries like pharmaceuticals or semiconductor manufacturing.

- If your primary focus is handling aggressive chemicals: PTFE's near-total chemical inertness makes it the safest and most reliable option for components like seats, seals, and gaskets.

- If your primary focus is low-torque or automated operation: The self-lubricating, low-friction nature of PTFE seats, bearings, and stem seals is critical for ensuring smooth and efficient actuation.

By understanding which components are made of PTFE and why, you can better select a valve that ensures the safety, purity, and efficiency of your system.

Summary Table:

| PTFE Component | Primary Function | Key Benefit |

|---|---|---|

| Body | Main housing and pressure boundary | Total chemical inertness for the fluid path |

| Ball | Rotating element controlling flow | Non-stick surface and smooth, low-torque operation |

| Stem | Connects actuator to the ball | Low friction movement, reducing wear and operating force |

| Seats & Seals | Creates a bubble-tight shutoff | Reliable sealing against aggressive media |

| Gaskets | Creates static seals between parts | Prevents external leaks in corrosive environments |

Need a reliable PTFE component for your critical application? KINTEK specializes in manufacturing high-precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. We ensure your systems operate with ultimate purity, chemical resistance, and efficiency—from prototype to high-volume production. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE an ideal material for bellows applications? Achieve Superior Sealing & Flexibility

- How is structured PTFE manufactured? The Process Behind High-Performance PTFE Components

- What additional safety feature do PTFE compensators provide? Prevent Electrical Sparks in Hazardous Environments

- What is the temperature range for PTFE spacer rings? A Guide to Extreme Thermal Stability

- What special requirements do aerospace applications have for PTFE O-ring seals? Ensuring Reliability in Extreme Environments

- What is the temperature rating for PTFE gaskets? Maximize Performance from -200°C to 260°C

- What are the drawbacks of using PTFE for sealing needs? The Critical Trade-offs in Chemical vs. Mechanical Performance

- Why are PTFE washers advantageous in mechanical assemblies? Enhance Performance & Durability