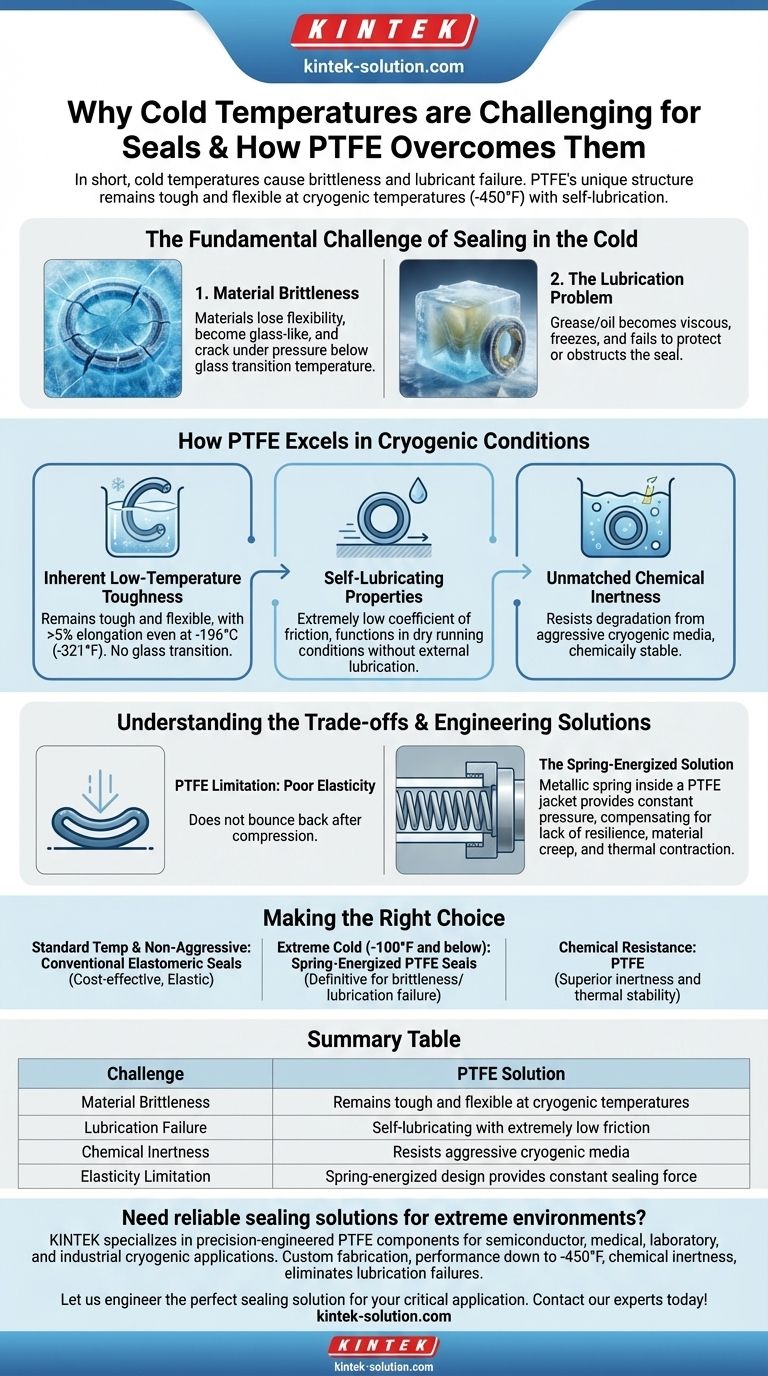

In short, cold temperatures are challenging for seals because they cause most materials to become brittle and crack, while also freezing the lubricants required for their operation. Polytetrafluoroethylene (PTFE) overcomes these issues due to its unique molecular structure, which allows it to remain tough and flexible at cryogenic temperatures down to -450°F and function without lubrication due to its extremely low friction.

The core problem in cold-temperature sealing isn't just the cold itself, but its dual effect on materials: it induces brittleness in the seal and solidifies its lubricant. PTFE is a superior solution because its inherent properties directly counteract both of these fundamental failure modes.

The Fundamental Challenge of Sealing in the Cold

To understand why PTFE is so effective, we must first analyze the two primary ways cold temperatures cause conventional seals to fail.

Material Brittleness: The Primary Failure Point

Most polymer materials, like standard elastomers, have a "glass transition temperature." Below this point, their molecular structure becomes rigid and glass-like.

A seal operating below this temperature loses its flexibility, can no longer conform to mating surfaces, and is highly susceptible to cracking under pressure or vibration.

The Lubrication Problem

Many sealing systems rely on grease or oil to reduce friction and wear. As temperatures drop, these lubricants become increasingly viscous.

Eventually, they freeze solid. A frozen lubricant not only fails to protect the seal but can also act as an abrasive or completely obstruct the sealing mechanism, leading to catastrophic failure.

How PTFE Excels in Cryogenic Conditions

PTFE's material properties are uniquely suited to solve the dual challenges of brittleness and lubrication in extreme cold.

Inherent Low-Temperature Toughness

PTFE does not have a true glass transition temperature and remains remarkably tough and flexible in extreme cold. It can maintain meaningful mechanical properties, such as 5% elongation, even at temperatures as low as -196°C (-321°F).

This allows a PTFE seal to maintain its shape and sealing force even when exposed to cryogenic fluids like liquid nitrogen.

Self-Lubricating Properties

PTFE has one of the lowest coefficients of friction of any solid material. This allows it to function in "dry running" conditions without any external liquid or grease lubricants.

This property completely bypasses the problem of frozen lubricants, ensuring consistent, low-friction performance regardless of the temperature.

Unmatched Chemical Inertness

Beyond its thermal stability, PTFE is almost universally chemically inert. This is critical when sealing aggressive cryogenic media, ensuring the seal material itself does not degrade upon contact with the process fluid.

Understanding the Trade-offs and Engineering Solutions

While highly effective, PTFE is not a perfect material. Its limitations are addressed through intelligent seal design.

The Elasticity Challenge

A primary drawback of raw PTFE is its poor elasticity, or "memory." Unlike a rubber O-ring, it does not readily spring back to its original shape after being compressed.

The Spring-Energized Solution

To overcome this, high-performance PTFE seals are typically spring-energized. A metallic spring is placed inside a precisely machined PTFE "jacket."

This spring provides constant, uniform pressure, forcing the seal lips against the hardware. It effectively compensates for PTFE's lack of resilience, material creep, and thermal contraction at low temperatures, ensuring a tight seal.

Cost vs. Performance

PTFE seals are more costly than standard elastomeric seals. However, this cost is justified in critical applications where seal failure is not an option and extreme temperatures make conventional solutions obsolete.

Making the Right Choice for Your Application

Selecting a sealing material requires matching its properties to the specific demands of the environment.

- If your primary focus is on standard operating temperatures without aggressive chemicals: Conventional elastomeric seals are often more cost-effective and provide superior elasticity.

- If your primary focus is extreme cold or cryogenic service (-100°F and below): Spring-energized PTFE seals are the definitive choice, engineered specifically to overcome material brittleness and lubrication failure.

- If your primary focus is chemical resistance across a wide temperature range: PTFE's chemical inertness and broad thermal stability make it a superior choice for sealing aggressive media.

Ultimately, choosing the right seal is about understanding the fundamental physics of your operating environment and selecting the material engineered to master it.

Summary Table:

| Challenge | PTFE Solution |

|---|---|

| Material Brittleness | Remains tough and flexible at cryogenic temperatures |

| Lubrication Failure | Self-lubricating with extremely low friction |

| Chemical Inertness | Resists aggressive cryogenic media |

| Elasticity Limitation | Spring-energized design provides constant sealing force |

Need reliable sealing solutions for extreme environments?

KINTEK specializes in precision-engineered PTFE components that excel where conventional seals fail. Our spring-energized PTFE seals are designed specifically for cryogenic applications in semiconductor, medical, laboratory, and industrial settings.

We provide:

- Custom fabrication from prototypes to high-volume orders

- Seals that maintain performance down to -450°F

- Chemical inertness for aggressive media

- Solutions that eliminate lubrication failures

Let us engineer the perfect sealing solution for your critical application. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating